Content Menu

● Introduction to Room Type Drying Machines

>> Key Features of Room Type Drying Machines

● Industry Standards for Room Type Drying Machines

● Certifications and Compliance

● Benefits of Room Type Drying Machines

● Maintenance and Upkeep

● Customization and Flexibility

>> Customization Options

● Environmental Impact

>> Sustainable Practices

● Conclusion

● FAQs

>> 1. What are the main advantages of room type drying machines over traditional drying methods?

>> 2. What certifications are important for room type drying machines?

>> 3. How do room type drying machines improve product quality?

>> 4. What maintenance activities are necessary for room type drying machines?

>> 5. Can room type drying machines be used for a variety of food products?

● Citations:

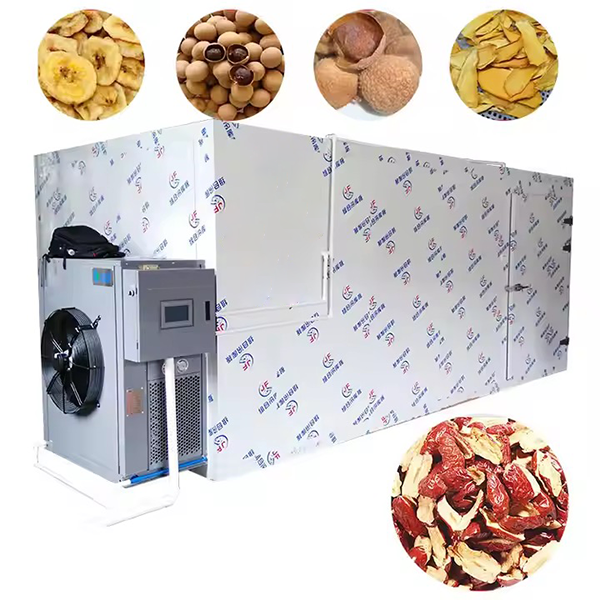

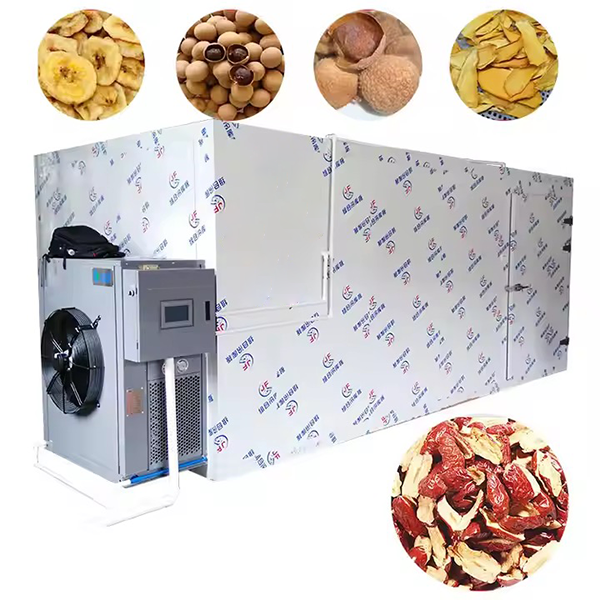

Room type drying machines, also known as food dryer rooms or drying chambers, are large-scale industrial systems designed to dry food products in a controlled environment. These machines consist of a sealed room equipped with heating elements, air circulation systems, and humidity controls to create optimal drying conditions. They are highly versatile and can be used to dry a wide range of food products, including fruits, vegetables, meats, fish, grains, herbs, and spices.

Introduction to Room Type Drying Machines

Room type drying machines offer significant advantages over traditional drying methods in terms of consistency, energy efficiency, product quality, and environmental sustainability. By providing a controlled environment for drying, these machines ensure uniform drying results, preserve nutritional value, and enhance food safety. As the food industry continues to evolve, the adoption of room type drying machines will play a crucial role in meeting the demands for high-quality dried food products while minimizing environmental impact.

Key Features of Room Type Drying Machines

1. Consistent Drying Results: The controlled environment ensures that all food products within the chamber receive equal exposure to heat and air circulation, resulting in evenly dried products.

2. Energy Efficiency: Modern room type drying machines are designed with energy efficiency in mind, incorporating heat recovery systems, insulation, and efficient air circulation mechanisms to minimize energy consumption.

3. Preservation of Nutritional Value: These machines operate at lower temperatures compared to traditional drying methods, which helps preserve the nutritional content and natural flavors of food products.

4. Year-Round Production: Unlike traditional sun drying methods, room type drying machines are not dependent on weather conditions, allowing for year-round production.

5. Advanced Control Systems: These machines often include touch screen interfaces, remote monitoring capabilities, data logging, and automated temperature and humidity controls, making them easy to operate and manage.

Industry Standards for Room Type Drying Machines

Industry standards play a crucial role in ensuring that room type drying machines meet the required safety, quality, and performance criteria. Some of the key certifications include:

- CE Certification: Ensures compliance with European Union health, safety, and environmental protection standards.

- ISO 22000: Focuses on food safety management systems, ensuring that the equipment meets international standards for food safety.

- HACCP (Hazard Analysis and Critical Control Points): A systematic approach to identifying and controlling hazards in the food production process.

- NSF Certification: Validates the ability of equipment to reduce microorganisms and prevent contamination.

Certifications and Compliance

Certifications are essential for room type drying machines as they provide assurance of quality, safety, and compliance with international regulations. Here are some key aspects of certification:

1. Design and Fabrication Standards: Manufacturers must adhere to specific design and fabrication standards to ensure that the equipment meets the required criteria for food processing.

2. Testing and Auditing: Rigorous testing and auditing processes are conducted to verify that the machines comply with the specified standards.

3. Documentation: Maintaining detailed documentation of the engineering design and technical construction file (EDTCF) is crucial for certification.

Benefits of Room Type Drying Machines

Room type drying machines offer several benefits over traditional drying methods:

- Improved Product Quality: By maintaining optimal drying conditions, these machines help preserve the nutritional content and natural flavors of food products.

- Increased Efficiency: They reduce drying time and energy consumption compared to other drying methods.

- Enhanced Safety: Advanced control systems and sanitization features ensure a safe and hygienic drying environment.

Maintenance and Upkeep

Regular maintenance is essential to ensure the optimal performance of room type drying machines. This includes:

- Cleaning: Regular cleaning of the chamber and components to prevent contamination.

- Air Filter Inspection: Ensuring that air filters are clean and functioning properly.

- Sensor Calibration: Regular calibration of temperature and humidity sensors.

- Lubrication: Lubricating moving parts to prevent wear and tear.

- Professional Maintenance Checks: Regular checks by professionals to identify and address any issues.

Customization and Flexibility

Room type drying machines can be customized to meet specific needs, offering flexibility in terms of size, temperature range, and humidity control. This allows manufacturers to tailor the drying process to the specific requirements of different food products, ensuring optimal drying conditions for each type of product.

Customization Options

1. Temperature Control: Adjustable temperature settings allow for precise control over the drying process, ensuring that products are dried at the optimal temperature.

2. Humidity Control: Advanced humidity management systems enable precise control over moisture levels, which is crucial for preventing over-drying or under-drying.

3. Air Circulation Systems: Customizable air circulation patterns ensure that air is evenly distributed throughout the chamber, promoting uniform drying.

Environmental Impact

Room type drying machines are designed with environmental sustainability in mind. By reducing energy consumption and minimizing waste, these machines contribute to a more sustainable food production process. Additionally, they help reduce the carbon footprint associated with traditional drying methods, such as sun drying, which can be affected by weather conditions and may require additional energy for processing.

Sustainable Practices

1. Energy Recovery Systems: Many modern room type drying machines incorporate energy recovery systems that reuse heat generated during the drying process, further reducing energy consumption.

2. Efficient Air Circulation: Optimized air circulation systems minimize the amount of energy needed to circulate air within the chamber.

3. Reduced Water Usage: By controlling humidity levels, these machines can reduce the need for additional water in the drying process.

Conclusion

Room type drying machines are a vital component in the food industry, offering consistent drying results, energy efficiency, and preservation of nutritional value. By adhering to industry standards and certifications, manufacturers can ensure that their equipment meets the highest quality and safety standards. As the demand for high-quality dried food products continues to grow, the adoption of room type drying machines will remain crucial for meeting these demands while minimizing environmental impact.

FAQs

1. What are the main advantages of room type drying machines over traditional drying methods?

- Room type drying machines offer consistent drying results, energy efficiency, preservation of nutritional value, and year-round production capabilities.

2. What certifications are important for room type drying machines?

- Key certifications include CE, ISO 22000, HACCP, and NSF, which ensure compliance with safety, quality, and performance standards.

3. How do room type drying machines improve product quality?

- These machines improve product quality by maintaining optimal drying conditions, preserving nutritional content, and enhancing food safety through advanced control systems and sanitization features.

4. What maintenance activities are necessary for room type drying machines?

- Regular activities include cleaning, air filter inspection, sensor calibration, lubrication of moving parts, and professional maintenance checks.

5. Can room type drying machines be used for a variety of food products?

- Yes, they are highly versatile and can be used to dry a wide range of food products, including fruits, vegetables, meats, fish, grains, herbs, and spices.

Citations:

[1] https://www.dryeratech.com/room-type-drying-machines-vs-traditional-drying-methods.html

[2] https://www.nsf.org/consumer-resources/articles/washer-dryer-certification

[3] https://workspace.oregonstate.edu/dried-dairy-products-certificate-osu-continuing-education

[4] http://pdf.dfcfw.com/pdf/H2_AN202306301591940897_1.pdf

[5] https://www.dryeratech.com/how-room-type-drying-machines-improve-product-quality.html

[6] https://www.ike.cn/certificate.html

[7] https://www.food-safety.com/articles/5008-certifying-process-equipment-whate28099s-involved

[8] http://static.cninfo.com.cn/finalpage/2004-06-11/14139912.PDF

[9] https://www.ok.org/article/spray-drying-and-kosher-certification-programs-how-to-make-them-work-together/