Content Menu

● Introduction to Room Type Drying Machines

>> Key Features of Room Type Drying Machines

● Traditional Drying Methods

● Comparison of Room Type Drying Machines and Traditional Drying Methods

● Benefits of Room Type Drying Machines

● Maintenance and Optimization of Room Type Drying Machines

● Future Innovations in Room Type Drying Machines

● Case Studies: Successful Implementation of Room Type Drying Machines

● Conclusion

● FAQ

>> 1. What are the primary benefits of using room type drying machines?

>> 2. How do room type drying machines contribute to environmental sustainability?

>> 3. What types of food products can be dried using room type drying machines?

>> 4. How do room type drying machines compare to traditional drying methods in terms of production capacity?

>> 5. What maintenance is required for room type drying machines to ensure optimal performance?

● Citations:

In the food processing industry, drying is a crucial step for preserving food products by removing moisture, thereby inhibiting the growth of microorganisms and extending shelf life. Traditional drying methods, such as sun drying, have been used for centuries, but they have limitations in terms of efficiency, consistency, and environmental impact. In contrast, modern room type drying machines offer a controlled environment that ensures uniform drying, energy efficiency, and superior product quality. This article will explore the advantages of room type drying machines over traditional drying methods, highlighting their benefits in food safety, production efficiency, and environmental sustainability.

Introduction to Room Type Drying Machines

Room type drying machines, also known as food dryer rooms or drying chambers, are large-scale industrial systems designed to dry food products in a controlled environment. These machines consist of a sealed room equipped with heating elements, air circulation systems, and humidity controls to create optimal drying conditions. They are highly versatile and can be used to dry a wide range of food products, including fruits, vegetables, meats, fish, grains, herbs, and spices.

Key Features of Room Type Drying Machines

1. Consistent Drying Results: The controlled environment ensures that all food products within the chamber receive equal exposure to heat and air circulation, resulting in evenly dried products.

2. Energy Efficiency: Modern room type drying machines are designed with energy efficiency in mind, incorporating heat recovery systems, insulation, and efficient air circulation mechanisms to minimize energy consumption.

3. Preservation of Nutritional Value: These machines operate at lower temperatures compared to traditional drying methods, which helps preserve the nutritional content and natural flavors of food products.

4. Year-Round Production: Unlike traditional sun drying methods, room type drying machines are not dependent on weather conditions, allowing for year-round production.

5. Advanced Control Systems: These machines often include touch screen interfaces, remote monitoring capabilities, data logging, and automated temperature and humidity controls, making them easy to operate and manage.

Traditional Drying Methods

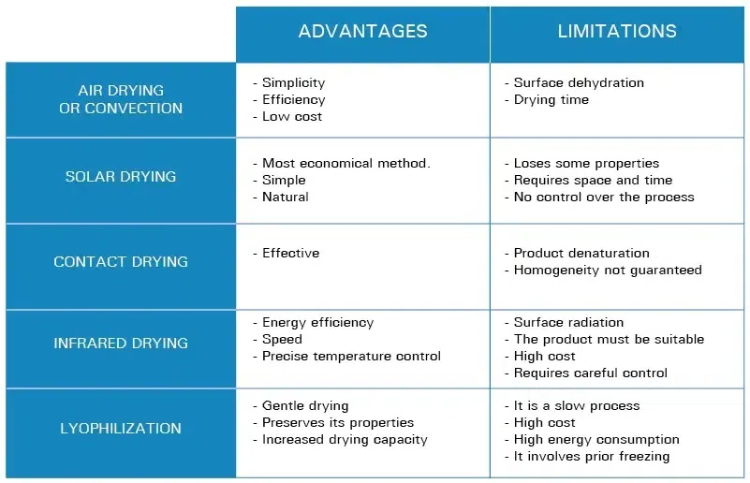

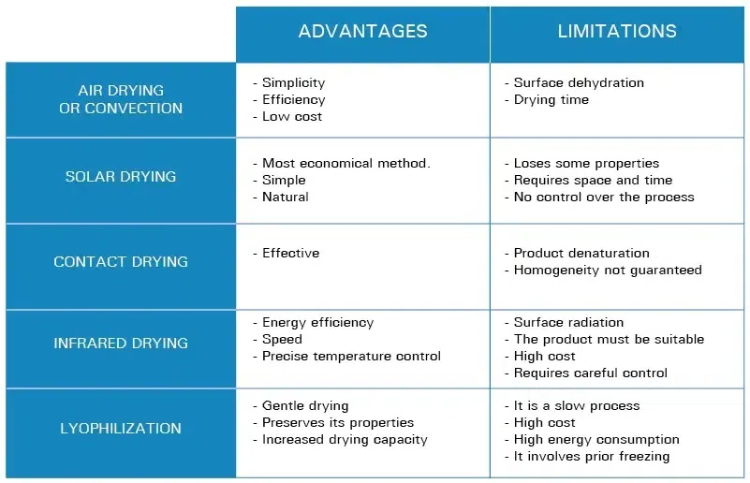

Traditional drying methods, such as sun drying, have been used for centuries. However, they have several drawbacks:

1. Dependence on Weather: Sun drying is heavily dependent on weather conditions, which can lead to inconsistent drying times and quality.

2. Risk of Contamination: Exposing food to the open environment increases the risk of contamination by dust, insects, and other external factors.

3. Limited Control Over Drying Conditions: It is difficult to control temperature and humidity levels, which can affect the quality and safety of the dried products.

Comparison of Room Type Drying Machines and Traditional Drying Methods

| Feature | Room Type Drying Machines | Traditional Drying Methods |

| Drying Consistency | Uniform drying due to controlled environment | Variable drying due to weather conditions |

| Energy Efficiency | Incorporates heat recovery systems for reduced energy consumption | Generally less efficient, especially in sun drying |

| Product Quality | Preserves nutritional value and flavor through gentle drying | Can lead to loss of nutrients and flavor due to high temperatures or prolonged exposure |

| Production Capacity | Can handle large volumes of food products | Limited by space and weather conditions |

| Environmental Impact | Reduces carbon footprint through energy efficiency | Can contribute to environmental degradation due to increased energy use or resource consumption |

Benefits of Room Type Drying Machines

1. Enhanced Food Safety: The controlled environment prevents external contamination and reduces the risk of microbial growth by removing moisture from food products.

2. Increased Production Efficiency: These machines can accommodate substantial volumes of food products, allowing manufacturers to increase their output and meet growing market demands.

3. Customization and Flexibility: Operators can adjust temperature, humidity, and airflow parameters to suit specific food products, ensuring optimal drying conditions for different types of foods.

4. Environmental Sustainability: By extending the shelf life of food products, room type drying machines help reduce food waste throughout the supply chain. Additionally, their energy efficiency translates to a lower carbon footprint compared to traditional drying methods.

5. Cost-Effectiveness: While the initial investment in room type drying machines may be higher, they offer long-term savings through reduced energy costs and increased productivity.

Maintenance and Optimization of Room Type Drying Machines

To ensure optimal performance of room type drying machines, regular maintenance is crucial:

- Cleaning and Sanitizing: Regularly clean and sanitize the drying chamber and trays to prevent contamination.

- Air Filter Inspection: Inspect and replace air filters as needed to maintain efficient air circulation.

- Sensor Calibration: Check and calibrate temperature and humidity sensors to ensure accurate readings.

- Lubrication of Moving Parts: Lubricate moving parts according to manufacturer specifications to reduce wear and tear.

- Professional Maintenance Checks: Schedule professional maintenance checks at recommended intervals to identify and address any issues promptly.

Future Innovations in Room Type Drying Machines

As technology continues to advance, we can expect several innovations in room type drying machines:

1. Artificial Intelligence Integration: AI-powered systems that can optimize drying parameters based on real-time data and product characteristics.

2. IoT Connectivity: Enhanced connectivity allowing for remote monitoring and control of multiple drying units across different locations.

3. Sustainable Energy Sources: Integration with renewable energy sources such as solar or wind power to further reduce environmental impact.

4. Advanced Sensor Technology: Implementation of more sophisticated sensors to monitor product quality throughout the drying process.

Case Studies: Successful Implementation of Room Type Drying Machines

Several companies have successfully integrated room type drying machines into their production lines, achieving significant improvements in product quality and production efficiency. For example, a leading fruit drying company in Europe reported a 30% increase in production capacity and a 25% reduction in energy costs after switching to room type drying machines. Similarly, a meat processing plant in the United States saw a notable decrease in product spoilage and an improvement in the overall quality of dried meats.

Conclusion

Room type drying machines offer significant advantages over traditional drying methods in terms of consistency, energy efficiency, product quality, and environmental sustainability. By providing a controlled environment for drying, these machines ensure uniform drying results, preserve nutritional value, and enhance food safety. As the food industry continues to evolve, the adoption of room type drying machines will play a crucial role in meeting the demands for high-quality dried food products while minimizing environmental impact.

FAQ

1. What are the primary benefits of using room type drying machines?

Room type drying machines provide consistent drying results, are energy-efficient, preserve nutritional value, and enhance food safety by controlling the drying environment.

2. How do room type drying machines contribute to environmental sustainability?

These machines reduce energy consumption through heat recovery systems, extend shelf life to reduce food waste, and decrease transportation costs by reducing the weight of dried products.

3. What types of food products can be dried using room type drying machines?

Room type drying machines are versatile and can be used to dry a wide range of food products, including fruits, vegetables, meats, fish, grains, herbs, and spices.

4. How do room type drying machines compare to traditional drying methods in terms of production capacity?

Room type drying machines can handle large volumes of food products, allowing for increased production capacity compared to traditional methods like sun drying.

5. What maintenance is required for room type drying machines to ensure optimal performance?

Regular cleaning, air filter inspection, sensor calibration, lubrication of moving parts, and professional maintenance checks are essential for maintaining optimal performance.

Citations:

[1] https://www.dryeratech.com/benefits-of-room-type-drying-machines.html

[2] https://www.dryeratech.com/hang-type-vs-traditional-dryers-which-is-better.html

[3] https://www.alamy.com/stock-photo/washer-dryer.html

[4] https://www.youtube.com/watch?v=SZ0vNsyQeBg

[5] https://www.alamy.com/stock-photo/sun-drying-food.html

[6] https://www.dryeratech.com/comparing-penetration-type-dryers-to-traditional-drying-methods.html

[7] https://www.youtube.com/watch?v=CpF80DuCzGs

[8] https://www.helperfoodmachine.com/food-drying-room/

[9] https://www.dryeratech.com/room-type-drying-machine.html

[10] https://airtekdehydrator.com/blog/how-to-create-a-drying-room/

[11] https://www.reddit.com/r/HomeImprovement/comments/jct5p0/washerdryer_combo_or_washing_machine_and_dryer/

[12] https://www.frigortec.com/en/know-how/technical-hay-drying-and-its-advantages

[13] https://www.istockphoto.com/photos/drying-machine

[14] https://www.shutterstock.com/search/food-preservation-drying

[15] https://stock.adobe.com/search?k=washer+dryer

[16] https://www.istockphoto.com/photos/drying-food

[17] https://www.istockphoto.com/photos/washer-dryer

[18] https://www.ginnos.com/blog/washer-combos-vs-laundry-pairs

[19] https://pmc.ncbi.nlm.nih.gov/articles/PMC7554907/

[20] https://www.youtube.com/watch?v=RMkfEdVdMGE