Content Menu

● Introduction to Fruit Dryer Machines

● The Importance of Fruit Dryer Machine Design

>> Key Components of Fruit Dryer Machine Design

● Types of Fruit Dryer Machines

>> 1. Hot Air Dryers

>> 2. Solar Dryers

>> 3. Freeze Dryers

>> 4. Heat Pump Dryers

● The Fruit Drying Process

● Benefits of Using Fruit Dryer Machines

● Applications of Fruit Dryer Machines

● Innovations in Fruit Dryer Machine Design

● Choosing the Right Fruit Dryer Machine

● Maintenance and Care of Fruit Dryer Machines

● Future Trends in Fruit Dryer Machine Design

● Conclusion

● Frequently Asked Questions

>> 1. What is the optimal temperature for drying fruits?

>> 2. How long does it take to dry fruits in a fruit dryer machine?

>> 3. Can I use a fruit dryer machine for other foods?

>> 4. How do I prevent fruits from browning during the drying process?

>> 5. Are solar fruit dryers as effective as electric ones?

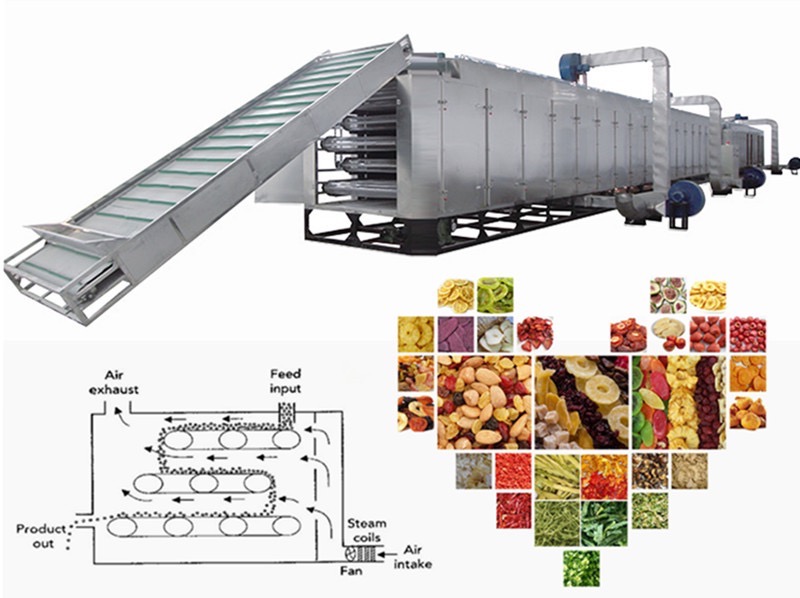

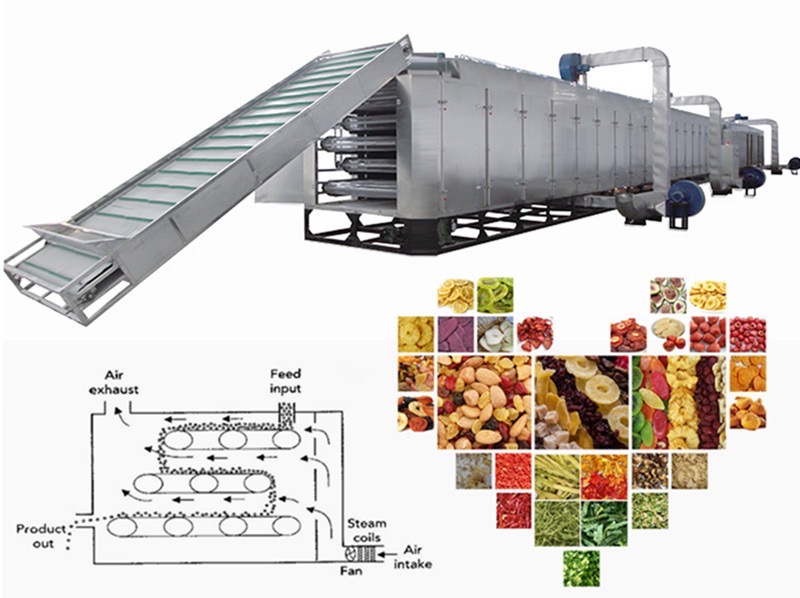

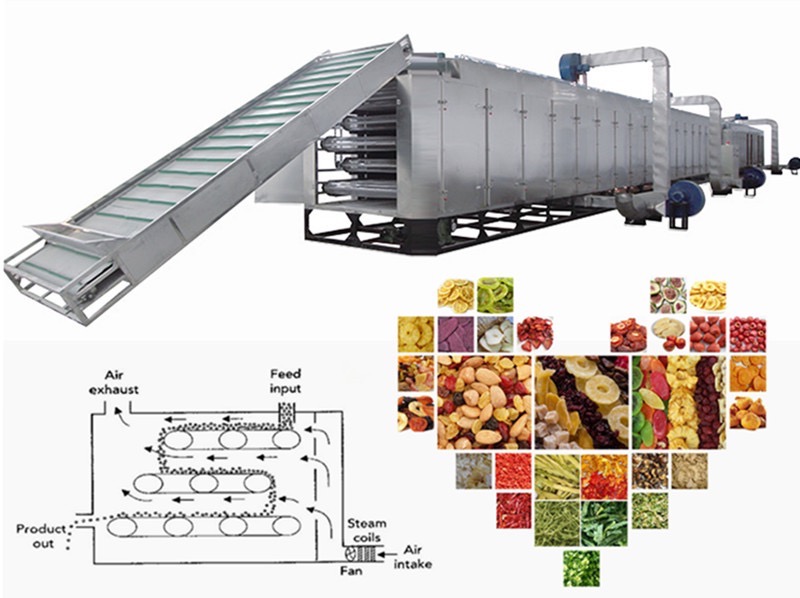

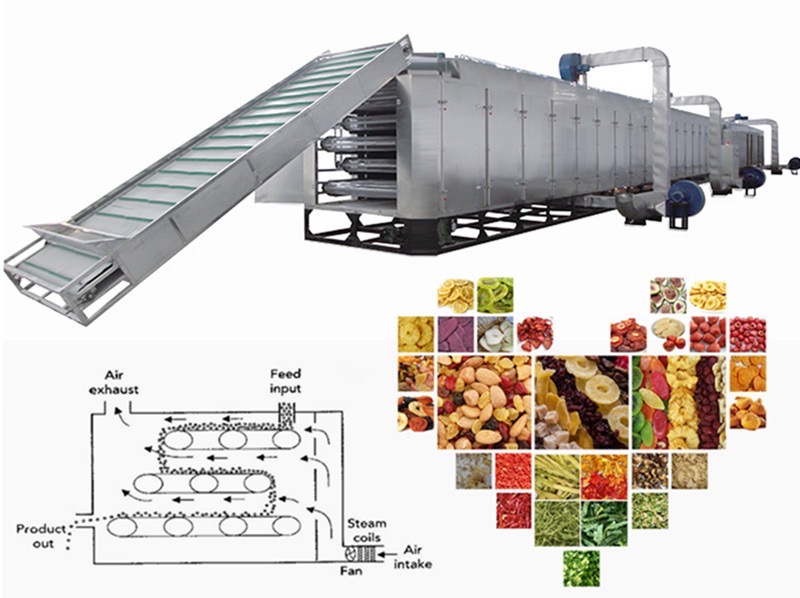

Introduction to Fruit Dryer Machines

Fruit dryer machines have become an essential tool in the food processing industry, offering an efficient and effective method for preserving fruits and vegetables while maintaining their nutritional value and flavor. These innovative devices have revolutionized the way we approach food preservation, providing numerous benefits for both commercial and home use.

The Importance of Fruit Dryer Machine Design

The design of a fruit dryer machine plays a crucial role in its effectiveness and efficiency. A well-designed fruit dryer ensures optimal performance, energy efficiency, and consistent results. The process of designing a fruit dryer machine involves careful consideration of various factors, including airflow, temperature control, and moisture removal.

Key Components of Fruit Dryer Machine Design

1. Drying Chamber: The heart of the machine where fruits are placed for dehydration.

2. Heating Element: Responsible for generating the heat required for the drying process.

3. Fan System: Ensures proper air circulation throughout the drying chamber.

4. Temperature Control: Maintains the optimal temperature for drying different types of fruits.

5. Trays or Racks: Hold the fruits during the drying process, allowing for even air distribution.

6. Control Panel: Allows users to adjust settings and monitor the drying process.

Types of Fruit Dryer Machines

There are several types of fruit dryer machines available, each with its unique design and advantages:

1. Hot Air Dryers

Hot air dryers are among the most common types of fruit dryer machines. They work by circulating heated air around the fruits, gradually removing moisture. These dryers are versatile and can handle a wide variety of fruits and vegetables.

2. Solar Dryers

Solar dryers harness the power of the sun to dry fruits naturally. These eco-friendly options are ideal for areas with abundant sunlight and can significantly reduce energy costs.

3. Freeze Dryers

Freeze dryers use a process called lyophilization to remove moisture from fruits at very low temperatures. This method helps preserve the fruit's structure and nutritional content better than other drying methods.

4. Heat Pump Dryers

Heat pump dryers are energy-efficient options that recirculate and dehumidify the air used in the drying process. They are particularly useful for drying temperature-sensitive fruits.

The Fruit Drying Process

Understanding the fruit drying process is essential for designing an effective fruit dryer machine. The process typically involves the following steps:

1. Preparation: Washing, peeling (if necessary), and slicing the fruits.

2. Pre-treatment: Applying treatments to prevent browning or enhance flavor.

3. Loading: Arranging the fruits on trays or racks within the dryer.

4. Drying: Exposing the fruits to controlled heat and airflow to remove moisture.

5. Cooling: Allowing the dried fruits to cool and equilibrate before packaging.

6. Packaging: Storing the dried fruits in airtight containers to maintain quality.

Benefits of Using Fruit Dryer Machines

Fruit dryer machines offer numerous advantages for both commercial and home users:

1. Extended shelf life of fruits and vegetables

2. Preservation of nutritional value

3. Reduction of food waste

4. Year-round availability of seasonal fruits

5. Cost-effective food preservation method

6. Compact storage of dried fruits

7. Enhanced flavor concentration in dried fruits

Applications of Fruit Dryer Machines

Fruit dryer machines find applications in various industries and settings:

1. Food Processing Industry: Large-scale production of dried fruits and vegetables

2. Agriculture: Preserving excess harvest and creating value-added products

3. Pharmaceuticals: Drying medicinal herbs and plants

4. Home Use: Personal food preservation and healthy snack preparation

5. Restaurants and Catering: Creating unique dried fruit ingredients for culinary use

Innovations in Fruit Dryer Machine Design

The field of fruit dryer machine design is constantly evolving, with new innovations emerging to improve efficiency and product quality:

1. Smart Controls: Integration of IoT technology for remote monitoring and control

2. Energy-Efficient Designs: Incorporation of renewable energy sources and heat recovery systems

3. Hybrid Drying Systems: Combining multiple drying technologies for optimal results

4. Customizable Drying Programs: Tailored settings for different types of fruits and desired outcomes

5. Compact and Modular Designs: Space-saving solutions for small-scale operations

Choosing the Right Fruit Dryer Machine

When selecting a fruit dryer machine, consider the following factors:

1. Capacity: Determine the volume of fruits you need to dry

2. Energy Efficiency: Look for models with high energy ratings

3. Temperature Range: Ensure the machine can accommodate the drying requirements of various fruits

4. Ease of Use: Choose a machine with user-friendly controls and easy maintenance

5. Durability: Opt for machines made with high-quality, food-grade materials

6. Cost: Consider both the initial investment and long-term operational costs

Maintenance and Care of Fruit Dryer Machines

Proper maintenance is crucial for ensuring the longevity and optimal performance of fruit dryer machines:

1. Regular Cleaning: Clean the drying chamber, trays, and filters after each use

2. Inspection: Check for any signs of wear or damage to components

3. Calibration: Periodically calibrate temperature and humidity sensors

4. Lubrication: Keep moving parts well-lubricated as per manufacturer instructions

5. Storage: Store the machine in a clean, dry place when not in use

Future Trends in Fruit Dryer Machine Design

The future of fruit dryer machine design looks promising, with several emerging trends:

1. Artificial Intelligence: Integration of AI for optimized drying processes

2. Sustainable Materials: Use of eco-friendly materials in machine construction

3. Nanotechnology: Application of nanocoatings for improved hygiene and efficiency

4. 3D Printing: Custom-designed components for specialized drying needs

5. Augmented Reality: AR-assisted maintenance and operation guides

Conclusion

Fruit dryer machine design has come a long way, offering innovative solutions for preserving fruits and vegetables while maintaining their nutritional value and flavor. As technology continues to advance, we can expect even more efficient and sophisticated designs that cater to the growing demand for high-quality dried fruits in various industries and households.

Frequently Asked Questions

1. What is the optimal temperature for drying fruits?

Answer: The optimal drying temperature for most fruits ranges between 125°F to 140°F (52°C to 60°C). However, this can vary depending on the specific fruit and desired outcome. Lower temperatures may be used for delicate fruits to preserve color and nutrients, while higher temperatures can be used for fruits with higher moisture content.

2. How long does it take to dry fruits in a fruit dryer machine?

Answer: The drying time can vary greatly depending on the type of fruit, its moisture content, the thickness of the slices, and the dryer's efficiency. On average, it can take anywhere from 6 to 36 hours. For example, thin apple slices might dry in 6-12 hours, while whole strawberries could take 24-36 hours.

3. Can I use a fruit dryer machine for other foods?

Answer: Yes, most fruit dryer machines are versatile and can be used for drying a variety of foods, including vegetables, herbs, meats (for jerky), and even flowers. Always check the manufacturer's guidelines for specific recommendations on different food types.

4. How do I prevent fruits from browning during the drying process?

Answer: To prevent browning, you can pre-treat fruits before drying. Common methods include dipping sliced fruits in lemon juice or ascorbic acid solution, or using commercial anti-browning agents. Some fruit dryer machines also come with features that help minimize browning during the drying process.

5. Are solar fruit dryers as effective as electric ones?

Answer: Solar fruit dryers can be very effective, especially in areas with abundant sunlight. While they may take longer to dry fruits compared to electric dryers, they are more energy-efficient and eco-friendly. The effectiveness of solar dryers depends on factors such as sunlight intensity, ambient temperature, and humidity levels. In optimal conditions, solar dryers can produce high-quality dried fruits comparable to those dried in electric machines.