Content Menu

● Introduction

● Understanding Heat Pump Herb Drying Technology

>> How Heat Pump Dehydration Works

>> Advantages of Heat Pump Herb Drying

● Applications in the Herb Industry

>> Culinary Herbs

>> Medicinal Herbs

>> Tea Production

>> Essential Oil Production

● Optimizing Herb Quality Through Advanced Drying Techniques

>> Temperature Control

>> Humidity Management

>> Airflow Optimization

>> Preservation of Bioactive Compounds

● Energy Efficiency and Sustainability in Herb Dehydration

>> Reduced Energy Consumption

>> Water Conservation

>> Reduced Emissions

>> Longevity and Durability

● Economic Benefits of Heat Pump Drying for Herb Processors

>> Reduced Operating Costs

>> Improved Product Quality

>> Increased Production Capacity

>> Year-Round Production

● Challenges and Considerations

>> Initial Investment

>> Technical Expertise

>> Product-Specific Optimization

>> Regulatory Compliance

● Future Trends in Commercial Herb Dehydration

>> Integration of Artificial Intelligence

>> Hybrid Drying Systems

>> Miniaturization

>> Enhanced Sensor Technology

● Conclusion

● Frequently Asked Questions

>> 1. What is the main advantage of using heat pump technology for commercial herb dehydration?

>> 2. How does heat pump drying affect the quality of dried herbs compared to traditional methods?

>> 3. Is commercial herb dehydration with heat pump technology suitable for all types of herbs?

>> 4. What are the initial costs associated with implementing a heat pump drying system for commercial herb dehydration?

>> 5. How does commercial herb dehydration with heat pump technology contribute to sustainability in the herb industry?

Introduction

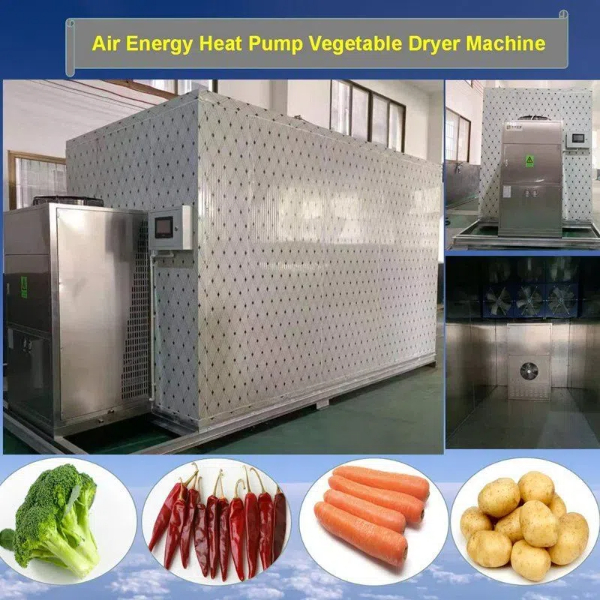

In the ever-evolving world of food processing and preservation, commercial herb dehydration with heat pump technology has emerged as a game-changer. This innovative approach combines the principles of heat transfer and moisture removal to create an efficient, cost-effective, and quality-preserving method for drying herbs and specialty crops. As the demand for dried herbs continues to rise in various industries, including culinary, pharmaceutical, and cosmetic sectors, the need for advanced dehydration techniques has never been more critical.

Understanding Heat Pump Herb Drying Technology

Heat pump herb drying technology represents a significant leap forward in the field of commercial herb dehydration. Unlike traditional drying methods that rely solely on heat, this system utilizes a closed-loop process that efficiently removes moisture while maintaining the essential qualities of the herbs.

How Heat Pump Dehydration Works

The process of commercial herb dehydration with heat pump technology involves several key steps:

1. Air Circulation: The system circulates air through the drying chamber, where the herbs are placed.

2. Moisture Extraction: As the air passes over the herbs, it absorbs moisture from them.

3. Condensation: The moisture-laden air then passes over the evaporator coils of the heat pump, where it cools and condenses.

4. Heat Recovery: The heat pump transfers the recovered heat back into the drying chamber, reheating the air.

5. Continuous Cycle: This process repeats, creating a closed-loop system that efficiently removes moisture from the herbs.

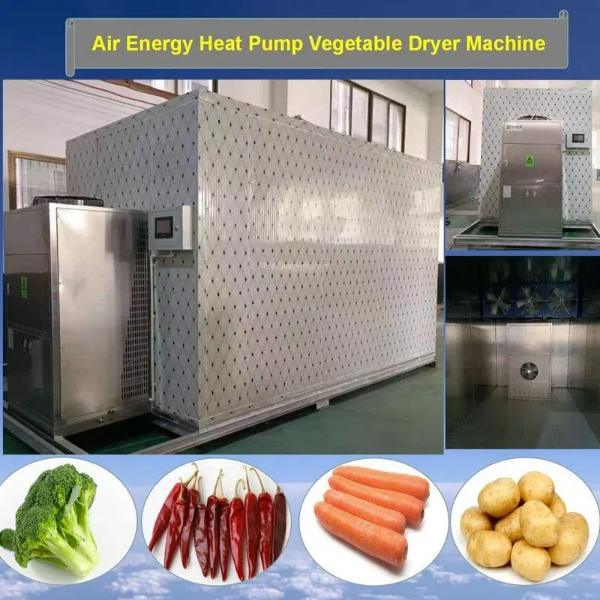

Advantages of Heat Pump Herb Drying

Commercial herb dehydration with heat pump technology offers numerous benefits over conventional drying methods:

1. Energy Efficiency: Heat pump systems can be up to 60% more energy-efficient than traditional drying methods.

2. Temperature Control: Precise temperature control allows for optimal drying conditions, preserving the herbs' quality.

3. Humidity Management: The ability to manage humidity levels ensures consistent drying results.

4. Gentle Drying Process: Lower drying temperatures help maintain the herbs' color, flavor, and nutritional value.

5. Year-round Operation: Heat pump systems can operate efficiently in various climatic conditions.

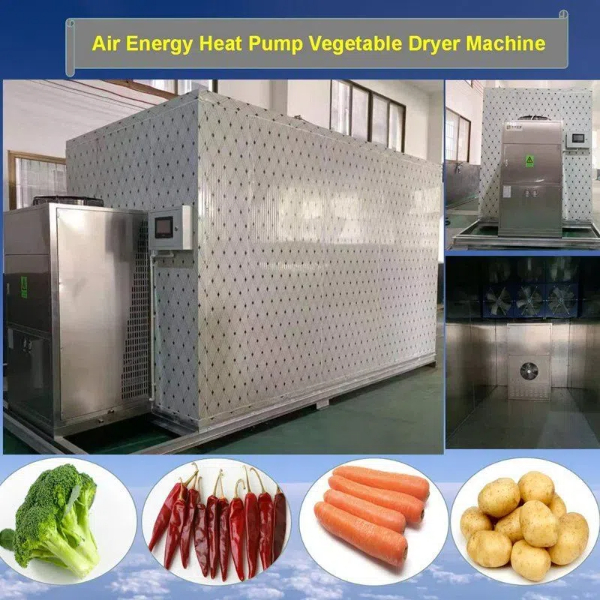

Applications in the Herb Industry

The versatility of commercial herb dehydration with heat pump technology makes it suitable for a wide range of applications within the herb industry.

Culinary Herbs

From basil and oregano to thyme and rosemary, culinary herbs benefit greatly from heat pump drying. The gentle process preserves the herbs' essential oils, ensuring that their flavors and aromas remain intact. This is crucial for the food industry, where the quality of dried herbs directly impacts the final product's taste.

Medicinal Herbs

For medicinal herbs, maintaining the potency of active compounds is paramount. Heat pump herb drying technology provides a controlled environment that minimizes degradation of these valuable components. This is particularly important for herbs used in traditional medicine and pharmaceutical products.

Tea Production

The tea industry has also embraced commercial herb dehydration with heat pump technology. Whether it's for herbal teas or flavored blends, this method ensures that the dried leaves retain their flavor profiles and beneficial properties.

Essential Oil Production

Before extraction, many herbs used for essential oils undergo a drying process. Heat pump drying helps preserve the volatile compounds responsible for the oils' therapeutic properties, resulting in higher-quality end products.

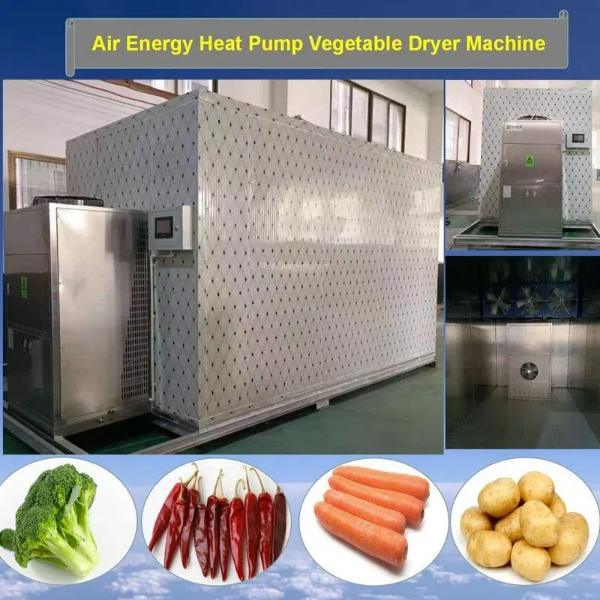

Optimizing Herb Quality Through Advanced Drying Techniques

One of the primary advantages of commercial herb dehydration with heat pump technology is its ability to optimize herb quality. This is achieved through several key factors:

Temperature Control

Heat pump systems allow for precise temperature control throughout the drying process. This is crucial because different herbs have varying optimal drying temperatures. For example, delicate herbs like cilantro may require lower temperatures, while hardier herbs like rosemary can withstand slightly higher temperatures.

Humidity Management

The ability to manage humidity levels during the drying process is another critical factor in maintaining herb quality. By controlling the relative humidity in the drying chamber, processors can ensure that moisture is removed evenly from the herbs, preventing issues like case hardening or mold growth.

Airflow Optimization

Proper airflow is essential for uniform drying. Heat pump systems can be designed to provide optimal air circulation, ensuring that all herbs in the batch are dried consistently. This is particularly important for large-scale commercial operations where uniformity is key.

Preservation of Bioactive Compounds

Many herbs contain valuable bioactive compounds, such as antioxidants, flavonoids, and essential oils. The gentle drying process of heat pump technology helps preserve these compounds, maintaining the herbs' nutritional and therapeutic value.

Energy Efficiency and Sustainability in Herb Dehydration

As the global focus on sustainability intensifies, the herb industry is under increasing pressure to adopt more environmentally friendly practices. Commercial herb dehydration with heat pump technology offers a solution that aligns with these sustainability goals.

Reduced Energy Consumption

Heat pump systems are inherently more energy-efficient than conventional drying methods. By recovering and reusing heat, these systems can significantly reduce overall energy consumption. This not only lowers operational costs but also reduces the carbon footprint of the drying process.

Water Conservation

Unlike some traditional drying methods that may require water for cooling or steam generation, heat pump systems operate in a closed loop, minimizing water usage. This is particularly beneficial in regions where water scarcity is a concern.

Reduced Emissions

The increased energy efficiency of heat pump drying systems translates to lower greenhouse gas emissions. This is an important consideration for companies looking to reduce their environmental impact and meet increasingly stringent regulations.

Longevity and Durability

Commercial herb dehydration equipment utilizing heat pump technology is often built for longevity. The robust design and fewer moving parts compared to some traditional systems mean less wear and tear, reducing the need for frequent replacements and the associated environmental impact.

Economic Benefits of Heat Pump Drying for Herb Processors

Adopting commercial herb dehydration with heat pump technology can provide significant economic benefits for herb processors and manufacturers.

Reduced Operating Costs

The energy efficiency of heat pump systems directly translates to lower operating costs. While the initial investment may be higher than some traditional drying methods, the long-term savings in energy consumption can result in a favorable return on investment.

Improved Product Quality

The superior quality of herbs dried using heat pump technology can command higher prices in the market. Consumers and industrial buyers alike are willing to pay a premium for herbs that retain more of their natural flavor, color, and nutritional value.

Increased Production Capacity

Heat pump drying systems often have faster drying times compared to traditional methods. This increased efficiency can lead to higher production capacities, allowing processors to meet growing market demands without significantly expanding their physical footprint.

Year-Round Production

The ability to operate efficiently in various climatic conditions means that herb processors can maintain consistent production throughout the year. This is particularly advantageous for businesses looking to stabilize their supply chain and meet year-round demand.

Challenges and Considerations

While commercial herb dehydration with heat pump technology offers numerous benefits, there are also challenges and considerations that industry professionals must address.

Initial Investment

The upfront cost of implementing a heat pump drying system can be significant. Processors must carefully evaluate the long-term benefits against the initial investment to determine the feasibility for their operations.

Technical Expertise

Operating and maintaining heat pump drying systems requires specialized knowledge. Companies may need to invest in training for their staff or hire experts to ensure optimal system performance.

Product-Specific Optimization

Different herbs may require specific drying parameters for optimal results. Processors must be prepared to invest time and resources in fine-tuning their systems for each type of herb they process.

Regulatory Compliance

As with any food processing technology, heat pump drying systems must comply with relevant food safety regulations. This may require additional documentation and quality control measures.

Future Trends in Commercial Herb Dehydration

The field of commercial herb dehydration with heat pump technology continues to evolve, with several exciting trends on the horizon.

Integration of Artificial Intelligence

AI-powered systems are being developed to optimize drying parameters in real-time, further improving efficiency and product quality.

Hybrid Drying Systems

Researchers are exploring the combination of heat pump technology with other drying methods, such as microwave or infrared, to create even more efficient and effective drying solutions.

Miniaturization

As technology advances, we may see the development of smaller, more affordable heat pump drying systems, making this technology accessible to smaller-scale herb producers.

Enhanced Sensor Technology

Improved sensors and monitoring systems will allow for even more precise control over the drying process, ensuring consistent quality across batches.

Conclusion

Commercial herb dehydration with heat pump technology represents a significant advancement in the herb processing industry. By offering improved energy efficiency, superior product quality, and alignment with sustainability goals, this technology is poised to become the standard for herb drying in the coming years. As the industry continues to innovate and refine these systems, we can expect to see even greater benefits for producers, consumers, and the environment.

Frequently Asked Questions

1. What is the main advantage of using heat pump technology for commercial herb dehydration?

Answer: The main advantage of using heat pump technology for commercial herb dehydration is its energy efficiency. Heat pump systems can be up to 60% more energy-efficient than traditional drying methods, resulting in lower operating costs and reduced environmental impact. Additionally, the precise temperature and humidity control offered by heat pump systems helps preserve the quality, flavor, and nutritional value of the herbs.

2. How does heat pump drying affect the quality of dried herbs compared to traditional methods?

Answer: Heat pump drying generally results in higher quality dried herbs compared to traditional methods. The lower drying temperatures and controlled humidity levels help preserve the herbs' color, flavor, aroma, and nutritional value. This gentle drying process also helps maintain the integrity of essential oils and other bioactive compounds, resulting in a superior product that more closely resembles the fresh herb in terms of quality and potency.

3. Is commercial herb dehydration with heat pump technology suitable for all types of herbs?

Answer: While heat pump technology is versatile and can be used for a wide range of herbs, the specific drying parameters may need to be adjusted for different herb types. Most culinary and medicinal herbs respond well to heat pump drying, but some very delicate herbs or those with extremely high moisture content may require additional considerations or modifications to the drying process. It's important to optimize the drying parameters for each specific herb to achieve the best results.

4. What are the initial costs associated with implementing a heat pump drying system for commercial herb dehydration?

Answer: The initial costs for implementing a heat pump drying system can be significant and vary depending on the scale of the operation and the specific features of the system. Factors that influence the cost include the size of the drying chamber, the capacity of the heat pump, automation features, and any additional technologies integrated into the system. While the upfront investment is often higher than traditional drying methods, the long-term energy savings and improved product quality can offset these costs over time.

5. How does commercial herb dehydration with heat pump technology contribute to sustainability in the herb industry?

Answer: Commercial herb dehydration with heat pump technology contributes to sustainability in several ways:

1. Energy Efficiency: Heat pump systems use significantly less energy than conventional drying methods, reducing overall energy consumption and associated greenhouse gas emissions.

2. Water Conservation: These systems operate in a closed loop, minimizing water usage compared to some traditional drying methods.

3. Reduced Food Waste: The improved quality and shelf life of herbs dried with heat pump technology can lead to less waste throughout the supply chain.

4. Longevity of Equipment: Heat pump systems are often more durable and require less frequent replacement, reducing the environmental impact associated with manufacturing and disposing of equipment.

5. Year-round Production: The ability to operate efficiently in various climatic conditions allows for more consistent production, potentially reducing the need for long-distance transportation of herbs.