Content Menu

● Introduction to Room Type Drying Machines

>> Key Features

>> Benefits of Room Type Drying Machines

● Cost Considerations

>> Initial Investment

>> Operating Costs

>> Maintenance Costs

● Customization and Integration

● Advanced Features and Technologies

>> Integration with Smart Technologies

>> Environmental Impact

● Case Studies

● Comparison with Other Drying Methods

>> Freeze-Drying vs. Room Type Drying

>> Spray Drying vs. Room Type Drying

>> Sun Drying vs. Room Type Drying

● Future Developments

● Conclusion

● FAQs

>> 1. What is the typical capacity of room type drying machines?

>> 2. How do room type drying machines preserve nutritional value?

>> 3. What types of food can be dried using room type drying machines?

>> 4. How energy-efficient are room type drying machines?

>> 5. What maintenance is required for room type drying machines?

● Citations:

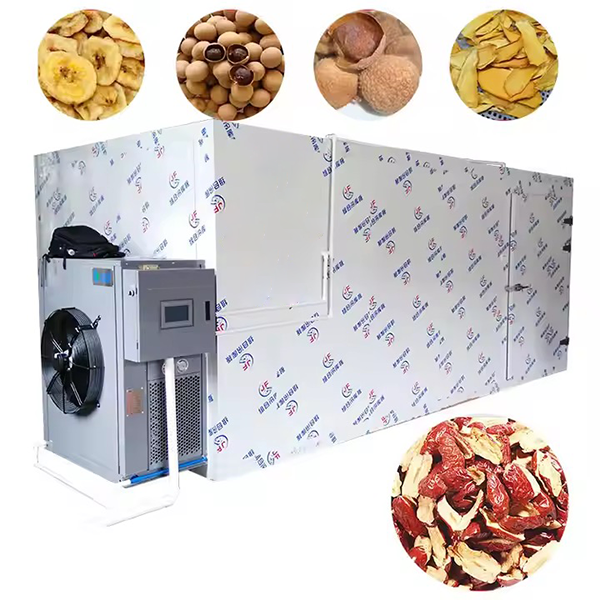

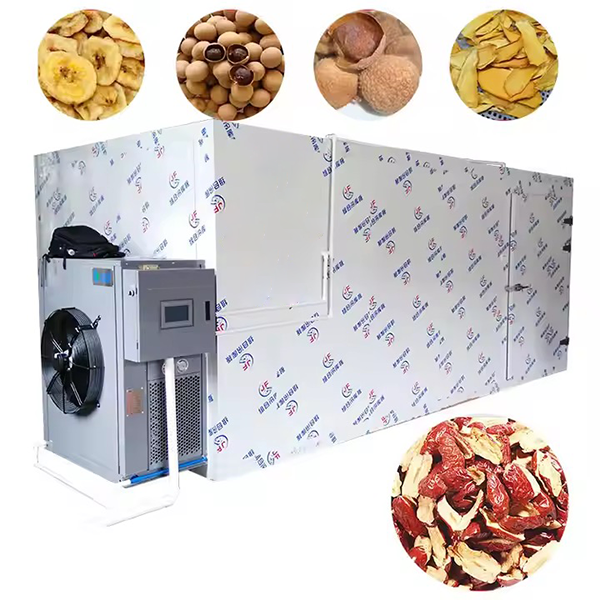

Room type drying machines have become an essential tool in the food industry, offering efficient and cost-effective solutions for drying a wide range of food products. These machines are designed to provide a controlled environment that ensures uniform drying, preserving the nutritional value and flavor of the food. In this article, we will delve into the cost aspects of room type drying machines, exploring their features, benefits, and what you can expect when investing in these machines.

Introduction to Room Type Drying Machines

Room type drying machines, also known as food dryer rooms or industrial drying chambers, utilize advanced technology to create a precise drying environment. They are equipped with features such as automatic temperature control, humidity regulation, and timed drying, ensuring rapid and uniform drying under ideal conditions. These machines are versatile and suitable for drying various products, including vegetables, fruits, meats, seafood, and medicinal herbs.

Key Features

1. Adjustable Temperature Settings: These machines allow operators to adjust the temperature according to the specific requirements of different food products. For instance, fruits typically require lower temperatures (around 40°C to 50°C), while meats may need higher temperatures (up to 70°C) for safe drying.

2. Proper Air Circulation: Strategically placed vents or fans ensure uniform airflow across all trays or shelves, preventing hot spots and ensuring consistent drying results.

3. Capacity and Customization: Room type drying machines often come with multiple drying trays or shelves, allowing for the drying of large batches and different types of food simultaneously. Customizable tray heights and drying racks accommodate foods of varying sizes and thicknesses.

4. Energy Efficiency: Features like insulated drying chambers and low-power fans reduce electricity consumption, making these machines cost-effective and environmentally friendly.

5. Advanced Control Systems: Modern machines include touch screen interfaces, remote monitoring capabilities, and automated temperature and humidity controls, ensuring precise control over the drying process.

Benefits of Room Type Drying Machines

- Consistent Product Quality: These machines provide uniform drying conditions, ensuring consistent product quality and reducing the risk of microbial growth due to moisture removal.

- Versatility: They can be used to dry a wide variety of food products, accommodating different shapes and sizes of food items.

- Energy Efficiency: Room type drying machines are generally more energy-efficient compared to traditional drying methods, incorporating heat recovery systems and efficient air circulation mechanisms.

- Nutritional Preservation: By controlling the drying environment, these machines help preserve the nutritional content and flavor of food products.

Cost Considerations

The cost of room type drying machines can vary widely depending on the capacity and features. For small-scale operations, the cost can range from about $3,500 to $7,500 for a basic setup capable of drying 100 kg of fresh pepper at a time. Larger industrial models, which can handle hundreds to thousands of kilograms, may cost between $8,000 and $40,000. For more extensive operations, prices can reach up to $50,000 or more, depending on the specific requirements and customization.

Initial Investment

The initial investment in purchasing and installing a room type drying machine is significant. However, these machines offer long-term benefits, including reduced energy costs and increased production capacity, which can offset the initial expenses.

Operating Costs

Despite the high initial cost, room type drying machines are designed to be energy-efficient, which reduces operational costs over time. Features like heat recovery systems and efficient air circulation mechanisms minimize energy consumption.

Maintenance Costs

Regular maintenance is necessary to ensure optimal performance. This includes cleaning the drying chamber, inspecting and replacing air filters, and calibrating temperature sensors.

Customization and Integration

Room type drying machines can be customized to meet specific industry requirements and production volumes. This includes adjustable tray heights and customizable drying racks to accommodate foods of varying sizes and thicknesses. These machines can also be integrated with other food processing equipment to create a seamless production line.

Advanced Features and Technologies

Modern room type drying machines often come with advanced features that enhance their functionality and efficiency:

- Digital Control Panels: Allow precise temperature and time settings.

- Automatic Shut-Off: Turns off the machine once the drying cycle is complete.

- Multiple Tray Layers: Increases capacity without increasing floor space.

- Real-Time Monitoring: Enables continuous monitoring of drying conditions.

Integration with Smart Technologies

The integration of smart technologies, such as IoT sensors and AI algorithms, further enhances the efficiency and precision of room type drying machines. These technologies enable real-time monitoring and predictive maintenance, reducing downtime and improving overall productivity.

Environmental Impact

Room type drying machines are designed to be environmentally friendly, using less energy compared to traditional drying methods. They also help reduce food waste by allowing for the preservation of seasonal produce throughout the year.

Case Studies

Several companies have successfully implemented room type drying machines in their operations, achieving significant improvements in product quality and cost savings. For example, a fruit processing company in Europe reported a 30% reduction in energy costs after switching to room type drying machines. Another company in Asia increased its production capacity by 50% without expanding its facility, thanks to the efficient design of these machines.

Comparison with Other Drying Methods

Room type drying machines are often compared to other drying methods such as freeze-drying, spray drying, and sun drying. While each method has its advantages, room type drying machines offer a balance of cost-effectiveness, nutritional preservation, and versatility.

Freeze-Drying vs. Room Type Drying

Freeze-drying, also known as lyophilization, is a method that removes moisture by freezing the product and then reducing the surrounding pressure to allow frozen water to sublimate directly into vapor. This method is excellent for preserving nutrients but is more expensive and energy-intensive compared to room type drying machines.

Spray Drying vs. Room Type Drying

Spray drying involves spraying a liquid into a hot gas stream, causing rapid evaporation of the water. This method is fast and efficient but often requires additional processing steps and can be less suitable for delicate products.

Sun Drying vs. Room Type Drying

Sun drying is a traditional method that relies on natural sunlight and airflow to dry food. While cost-effective, it is weather-dependent and can lead to inconsistent drying results and potential contamination.

Future Developments

As technology continues to evolve, room type drying machines are expected to become even more efficient and integrated with smart technologies. Future developments may include enhanced automation, improved energy recovery systems, and more advanced control systems that optimize drying conditions based on real-time data.

Conclusion

Room type drying machines offer a comprehensive solution for food drying, providing consistent quality, energy efficiency, and versatility. While the initial investment may seem high, the long-term benefits in terms of reduced operational costs and increased product value make them a valuable asset for businesses in the food processing industry.

FAQs

1. What is the typical capacity of room type drying machines?

Room type drying machines can handle capacities ranging from 100 kg to several tons per day, depending on the model and configuration. They are suitable for both small-scale and large-scale industrial applications.

2. How do room type drying machines preserve nutritional value?

These machines preserve nutritional value by controlling the drying environment, ensuring optimal temperature and humidity conditions that minimize nutrient loss. They are particularly effective in retaining vitamins and minerals compared to other drying methods.

3. What types of food can be dried using room type drying machines?

Room type drying machines are versatile and can be used to dry a wide range of food products, including fruits, vegetables, meats, seafood, and medicinal herbs.

4. How energy-efficient are room type drying machines?

Room type drying machines are designed to be energy-efficient, utilizing features like insulated drying chambers and low-power fans to reduce electricity consumption. They often incorporate heat recovery systems to further minimize energy waste.

5. What maintenance is required for room type drying machines?

Regular maintenance includes cleaning the drying chamber, inspecting and replacing air filters, and calibrating temperature sensors. Professional maintenance checks are recommended at regular intervals to ensure optimal performance.

Citations:

[1] https://www.bxdrymachine.com/how-much-is-the-price-of-pepper-drying-box-room.html

[2] https://www.helperfoodmachine.com/food-drying-room/

[3] https://www.dryeratech.com/room-type-drying-machine.html

[4] https://www.youtube.com/watch?v=A5Nf2P7-nbU

[5] https://www.dryeratech.com/how-room-type-drying-machines-improve-product-quality.html

[6] https://www.dryeratech.com/room-type-drying-machines-cost-vs-benefits.html

[7] https://www.bxdrymachine.com/faq

[8] https://www.dryeratech.com/common-mistakes-when-using-room-type-drying-machines.html

[9] https://www.bxdryer.com/news/industry-news/food-drying-machine-price-in-sri-lanka-news.html

[10] https://www.dryeratech.com/top-features-to-look-for-in-room-type-drying-machines.html

[11] https://www.dryeratech.com/room-type-drying-machines-a-comprehensive-guide.html

[12] https://www.alibaba.com/showroom/drying-room-equipment.html

[13] https://www.shutterstock.com/search/food-dryer

[14] https://www.shutterstock.com/search/drying-machines

[15] https://www.istockphoto.com/photos/food-dryer

[16] https://www.youtube.com/playlist?list=PLVkRkD7cOW-4mWUThghbW0qvk5z6H7JOS

[17] https://www.istockphoto.com/photos/drying-machine

[18] https://fs-wave.en.made-in-china.com/product/LAkRONXUEPWS/China-Electric-Heating-Drying-Room-for-Food-Industry-Vegetable-and-Fruit-Dehydration-Drying-Room.html

[19] https://www.linkedin.com/pulse/common-questions-food-dehydrators-aradmachinery

[20] https://frostx.com/en/blog/frequently-asked-questions-about-freeze-dryers-are-they-worth-it-and-who-are-they-for/

[21] https://www.appliancecity.co.uk/laundry/washer-dryers/washer-dryer-faqs/

[22] https://tunelgroup.com/drying-rooms-in-the-food-industry-essential-technology-for-long-term-food-storage/

[23] https://www.builtinpro.hk/en/tumble-dryers

[24] https://www.bxdrymachine.com/chili-dryer-price.html

[25] https://www.dryeratech.com/room-type-drying-machines-for-different-industries.html

[26] https://www.youtube.com/watch?v=-kDPB6X2-qo

[27] https://www.blomberg.co.uk/support/buying-guides/tumble-dryers