Content Menu

● Introduction to Penetration Type Dryers

>> Key Features of Penetration Type Dryers

● The Impact of Ambient Conditions

>> Ambient Temperature

>> Ambient Humidity

>> Air Circulation

● Optimizing Drying Performance

● Case Studies

● Advanced Technologies in Drying

>> Machine Learning in Drying

>> IoT Sensors

● Conclusion

● Frequently Asked Questions

>> 1. What are the key benefits of using penetration type dryers?

>> 2. How does ambient humidity affect the drying process?

>> 3. What role does air circulation play in drying performance?

>> 4. Can penetration type dryers be customized for specific drying requirements?

>> 5. How do smart technologies enhance the performance of penetration type dryers?

● Citations:

Penetration type dryers have become a cornerstone in the food industry, particularly for drying a wide range of products such as nuts, spices, seeds, beans, coffee beans, and cocoa beans. These dryers are renowned for their energy efficiency, uniform drying capabilities, and adjustable temperature controls. However, the performance of these machines can be significantly influenced by ambient conditions, which include factors like temperature, humidity, and air circulation. In this article, we will delve into the impact of ambient conditions on the performance of penetration type dryers and explore how these factors can be optimized for better drying outcomes.

Introduction to Penetration Type Dryers

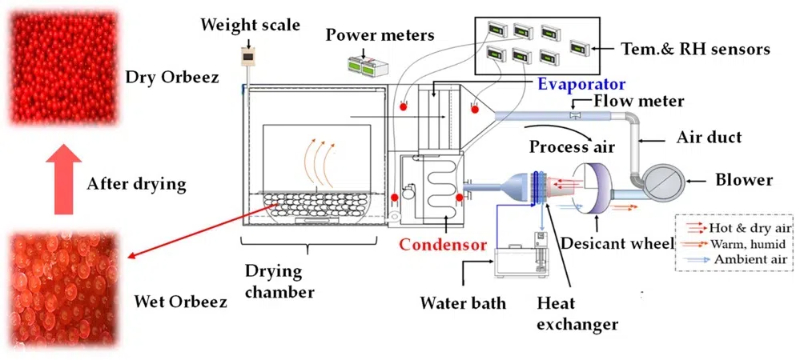

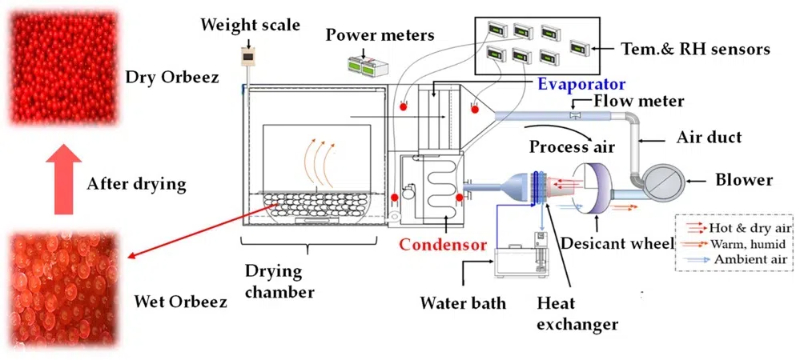

Penetration type dryers utilize a patented half-vacuum air duct design that allows hot air to penetrate evenly through stacked products. This design ensures uniform drying across all layers, even when products are densely packed. The adjustable temperature settings, ranging from 18°C to 80°C, enable hot drying, cool drying, and dehumidification functions, making these machines versatile for various food products.

Key Features of Penetration Type Dryers

1. Energy Efficiency: These dryers use only about 25% of the electricity required by traditional dryers, significantly reducing operational costs and environmental impact.

2. Uniform Drying: The half-vacuum system ensures that air penetrates evenly through stacked products, resulting in consistent moisture removal across all layers.

3. Temperature Control: Adjustable temperature settings allow for precise control over the drying process, suitable for a wide range of food products.

The Impact of Ambient Conditions

Ambient conditions play a crucial role in the drying performance of penetration type dryers. Factors such as ambient temperature, humidity, and air circulation can affect the efficiency and quality of the drying process.

Ambient Temperature

The ambient temperature affects the drying rate and energy consumption of the dryer. Higher ambient temperatures can increase the drying rate but may also lead to increased energy consumption if not properly managed. Conversely, lower ambient temperatures may slow down the drying process but can be more energy-efficient if utilized effectively.

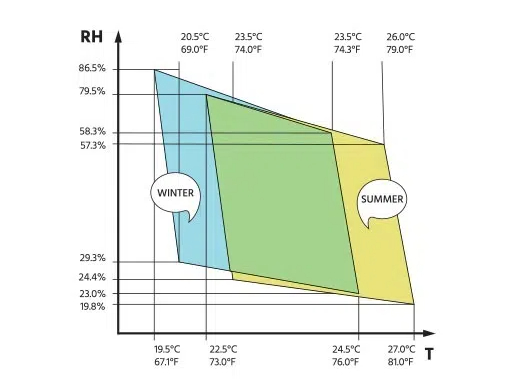

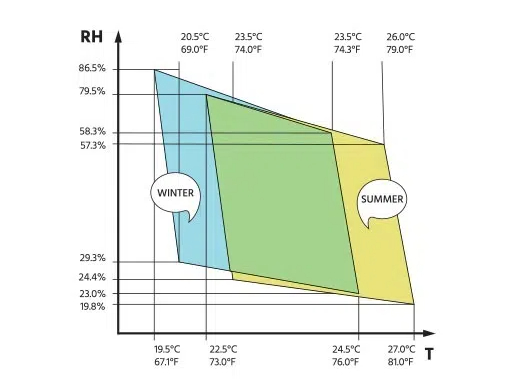

Ambient Humidity

Ambient humidity is another critical factor that influences drying performance. High humidity can delay the drying process by reducing the rate of moisture removal from the products. This can lead to longer drying times and potentially affect product quality.

Air Circulation

Proper air circulation is essential for efficient drying. The half-vacuum design in penetration type dryers ensures that air penetrates evenly through the products, but external air circulation can also impact the drying environment. Good air circulation helps maintain optimal drying conditions by preventing moisture buildup around the dryer.

Optimizing Drying Performance

To optimize the performance of penetration type dryers under various ambient conditions, several strategies can be employed:

1. Temperature Control Systems: Implementing advanced temperature control systems that can automatically adjust heating and cooling based on ambient conditions helps maintain optimal drying temperatures.

2. Humidity Management: Using dehumidification functions within the dryer or managing ambient humidity levels can enhance drying efficiency in humid environments.

3. Air Circulation Optimization: Ensuring good air circulation around the dryer and within the drying chamber is crucial for maintaining optimal drying conditions.

4. Predictive Maintenance: Regular maintenance and predictive analytics can help identify potential issues before they affect drying performance, ensuring continuous operation.

5. Smart Technologies: Integrating smart technologies, such as IoT sensors and AI algorithms, can optimize drying processes by monitoring temperature, humidity, and airflow in real-time. This allows for predictive maintenance and automatic adjustments to ensure optimal drying conditions.

Case Studies

Several food manufacturers have successfully optimized their drying processes using penetration type dryers:

- Nut Processing Facility: A facility in Asia reported a 30% reduction in energy costs and a 20% increase in production efficiency by using penetration type dryers for peanuts and almonds.

- Spice Drying Plant: A plant in Europe noted a 25% decrease in energy consumption and a 15% improvement in product quality when using penetration type dryers for cardamom and cloves.

- Coffee Bean Drying: A coffee roaster in South America achieved a 40% reduction in drying time and a 10% increase in coffee bean quality by optimizing ambient conditions and using smart technologies to monitor the drying process.

Advanced Technologies in Drying

The integration of advanced technologies is transforming the drying industry. Technologies such as machine learning and IoT sensors enable real-time monitoring and optimization of drying conditions, ensuring that products are dried under optimal conditions.

Machine Learning in Drying

Machine learning algorithms can analyze historical data to predict optimal drying conditions based on ambient temperature, humidity, and product type. This predictive capability allows for automatic adjustments to the drying process, ensuring consistent product quality and efficiency.

IoT Sensors

IoT sensors provide real-time data on temperature, humidity, and airflow within the drying chamber. This data can be used to adjust drying conditions in real-time, ensuring that products are dried efficiently and effectively.

Conclusion

Penetration type dryers offer significant advantages in the food industry due to their energy efficiency, uniform drying capabilities, and versatility. However, their performance can be influenced by ambient conditions such as temperature, humidity, and air circulation. By understanding and optimizing these factors, manufacturers can enhance drying efficiency, reduce costs, and improve product quality. The integration of smart technologies further enhances the performance of these dryers, allowing for real-time monitoring and optimization of drying processes.

Frequently Asked Questions

1. What are the key benefits of using penetration type dryers?

Penetration type dryers offer several benefits, including energy efficiency, uniform drying, and adjustable temperature controls. They use only 25% of the electricity required by traditional dryers, making them highly cost-effective and environmentally friendly.

2. How does ambient humidity affect the drying process?

High ambient humidity can delay the drying process by reducing the rate of moisture removal from products. This can lead to longer drying times and potentially affect product quality.

3. What role does air circulation play in drying performance?

Good air circulation is essential for maintaining optimal drying conditions. It helps prevent moisture buildup around the dryer, ensuring efficient drying and consistent product quality.

4. Can penetration type dryers be customized for specific drying requirements?

Yes, penetration type dryers can be customized to meet specific drying needs. They offer adjustable temperature and humidity controls, allowing different products to be dried under optimal conditions.

5. How do smart technologies enhance the performance of penetration type dryers?

Smart technologies, such as IoT sensors and AI algorithms, can optimize drying processes by monitoring temperature, humidity, and airflow in real-time. This allows for predictive maintenance and automatic adjustments to ensure optimal drying conditions.

Citations:

[1] https://www.dryeratech.com/energy-efficiency-the-advantage-of-penetration-type-dryers.html

[2] https://www.dryeratech.com/how-does-a-penetration-type-dryer-work-a-technical-overview.html

[3] https://patents.google.com/patent/CN110207480A/zh

[4] https://www.dryeratech.com/how-to-optimize-your-drying-process-with-a-penetration-type-dryer.html

[5] https://www.aimheatpump.com/products-78591

[6] https://patents.google.com/patent/CN1405396A/zh

[7] https://pmc.ncbi.nlm.nih.gov/articles/PMC8142616/

[8] https://www.researchgate.net/figure/Penetration-force-means-values-for-different-drying-methods_fig3_341548508

[9] https://patents.google.com/patent/WO2022068971A1/zh