Content Menu

● Introduction to Hang Type Dryers

● How Hang Type Dryers Work

● Environmental Benefits

>> 1. Energy Conservation

>> 2. Preservation of Food Quality

>> 3. Waste Reduction

>> 4. Space Efficiency

>> 5. Reduced Water Usage

● Applications of Hang Type Dryers

>> 1. Meat Processing

>> 2. Fruit and Vegetable Drying

>> 3. Herb Drying

>> 4. Seafood Drying

● Advantages Over Traditional Drying Methods

>> 1. Improved Airflow

>> 2. Enhanced Control Over Drying Parameters

>> 3. Lower Operating Costs

● Conclusion

● FAQ

>> 1. What types of foods can be dried using a hang type dryer?

>> 2. How does a hang type dryer differ from other types of dryers?

>> 3. Can hang type dryers help reduce my operational costs?

>> 4. Are there any maintenance requirements for hang type dryers?

>> 5. How do I choose the right hang type dryer for my business?

● Citations:

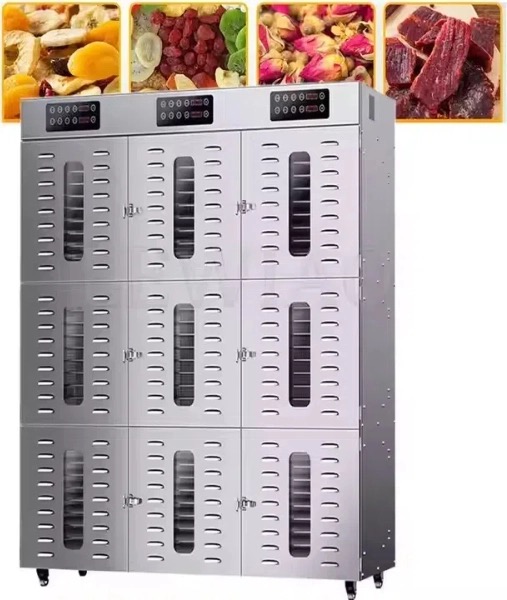

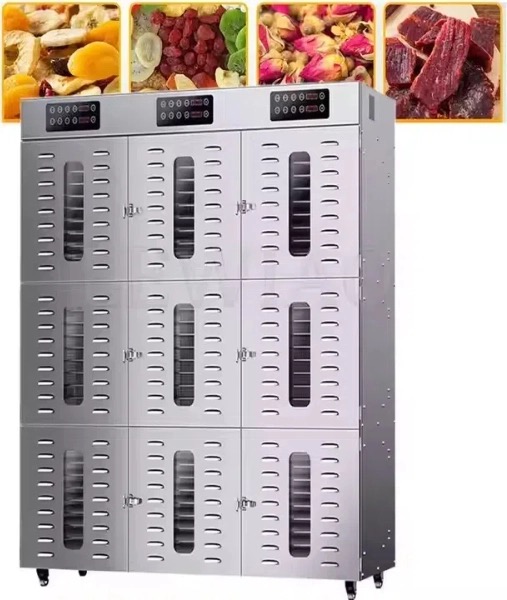

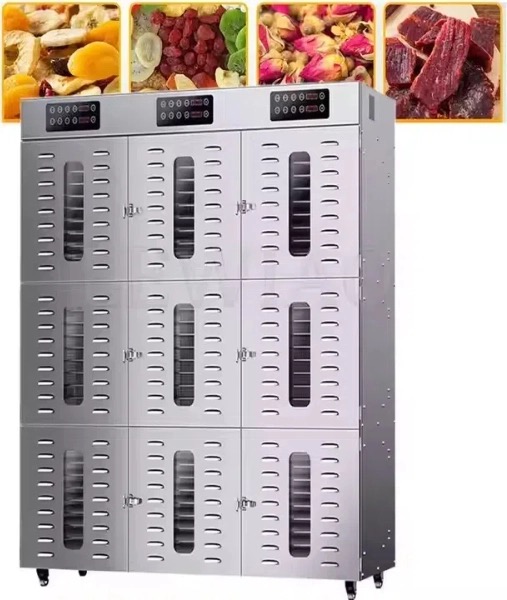

Hang type dryers have emerged as a pivotal technology in the food processing industry, particularly for drying various food items efficiently and sustainably. This article explores the environmental benefits of using hang type dryers, emphasizing their role in reducing energy consumption, preserving food quality, and enhancing operational efficiency.

Introduction to Hang Type Dryers

Hang type dryers are specialized machines designed to dry food products by suspending them from hangers in a controlled environment. They are particularly effective for drying items such as noodles, meats, fish, herbs, and fruits. This method ensures even drying and minimizes the risk of spoilage due to microbial growth.

How Hang Type Dryers Work

The operation of a hang type dryer involves several key components:

1. Suspended Arrangement: Food items are hung to maximize airflow around them, which accelerates the drying process.

2. Controlled Environment: These dryers maintain optimal temperature, humidity, and airflow, crucial for preserving the quality of the food being dried.

3. Energy Efficiency: Many modern hang type dryers utilize heat pump technology, which can reduce energy consumption by up to 75% compared to traditional drying methods.

Environmental Benefits

1. Energy Conservation

One of the most significant environmental benefits of hang type dryers is their energy efficiency. Traditional drying methods often consume large amounts of energy. In contrast, hang type dryers equipped with heat pump technology recycle heat within the system:

- Reduced Energy Use: By recycling heat, these dryers lower operational costs and minimize greenhouse gas emissions associated with energy production.

- Sustainable Practices: Utilizing renewable energy sources alongside these machines can further decrease the carbon footprint of food processing operations.

2. Preservation of Food Quality

Hang type dryers excel at maintaining the nutritional value and sensory qualities of food products:

- Nutrient Retention: Controlled drying processes help retain essential vitamins and minerals that might be lost in high-temperature drying methods.

- Flavor and Aroma Preservation: Gentle drying conditions prevent the degradation of volatile compounds responsible for flavor and aroma, ensuring that the final product is appealing to consumers.

3. Waste Reduction

The efficient drying process offered by hang type dryers contributes to waste reduction in several ways:

- Lower Spoilage Rates: By reducing moisture content effectively, these dryers prevent spoilage from microbial growth, extending the shelf life of food products.

- Optimized Production: The ability to dry various products uniformly means that manufacturers can minimize waste caused by over-drying or under-drying.

4. Space Efficiency

Hang type dryers are designed to optimize vertical space in production facilities:

- Maximized Production Capacity: By utilizing vertical arrangements for drying, manufacturers can increase their output without requiring extensive floor space.

- Flexibility in Production Layouts: This space efficiency allows for more flexible production layouts that can adapt to changing demands without significant capital investment in new machinery.

5. Reduced Water Usage

Water is a critical resource in food processing, and efficient drying methods can significantly reduce water consumption:

- Less Water Waste: Traditional drying methods often require substantial water usage for cleaning and processing. Hang type dryers minimize this need by providing a more efficient method that requires less water overall.

- Sustainable Water Management: By reducing water consumption, companies can contribute to sustainable water management practices, which is increasingly important in regions facing water scarcity.

Applications of Hang Type Dryers

Hang type dryers have a wide range of applications across various sectors in the food industry:

1. Meat Processing

In meat processing facilities, hang type dryers are used to produce dried meats such as jerky or cured sausages. The controlled environment helps prevent bacterial growth while enhancing flavor through proper dehydration techniques.

2. Fruit and Vegetable Drying

Fruits and vegetables are often dried for snacks or preservation purposes. Hang type dryers allow for uniform drying that retains color and texture while minimizing nutrient loss.

3. Herb Drying

Herbs require gentle handling to preserve their aromatic properties. Hang type dryers provide an ideal solution by allowing herbs to dry without crushing or bruising them during the process.

4. Seafood Drying

Seafood products like fish are commonly dried for preservation and flavor enhancement. The controlled conditions in hang type dryers ensure that seafood retains its natural flavors while extending its shelf life.

Advantages Over Traditional Drying Methods

Hang type dryers offer several advantages over traditional drying methods:

1. Improved Airflow

Traditional drying methods often struggle with airflow consistency, leading to uneven drying results. Hang type dryers ensure optimal airflow around each product, resulting in uniform moisture removal.

2. Enhanced Control Over Drying Parameters

With advanced technology integrated into hang type dryers, operators can precisely control temperature and humidity levels throughout the drying process. This level of control is often lacking in traditional methods.

3. Lower Operating Costs

Although the initial investment may be higher for hang type dryers compared to conventional systems, the long-term savings associated with reduced energy use and waste make them a cost-effective solution for many businesses.

Conclusion

In conclusion, hang type dryers represent a sustainable solution for food processing industries looking to improve their environmental footprint while maintaining high-quality products. From energy conservation and waste reduction to enhanced food quality and space efficiency, these machines provide numerous benefits that align with modern sustainability goals. As more companies adopt hang type dryer technology, we can expect significant advancements in eco-friendly practices within the food industry.

The transition towards using hang type dryers not only supports environmental sustainability but also enhances operational efficiency and product quality—key factors for success in today's competitive market.

FAQ

1. What types of foods can be dried using a hang type dryer?

Hang type dryers are suitable for a variety of foods including meats (like jerky), fruits (such as apples or bananas), vegetables (like tomatoes), herbs (like basil), and seafood (like fish).

2. How does a hang type dryer differ from other types of dryers?

Unlike traditional flatbed or conveyor belt dryers that may not provide uniform airflow or temperature control, hang type dryers utilize a suspended arrangement that maximizes airflow around each item for even drying.

3. Can hang type dryers help reduce my operational costs?

Yes! While they may require a higher initial investment, their energy efficiency can significantly lower operational costs over time by reducing energy consumption and minimizing waste.

4. Are there any maintenance requirements for hang type dryers?

Regular maintenance is essential to ensure optimal performance. This includes cleaning filters, checking heating elements, and inspecting airflow systems periodically to prevent clogs or inefficiencies.

5. How do I choose the right hang type dryer for my business?

When selecting a hang type dryer, consider factors such as capacity needs, energy efficiency ratings, available space in your facility, and specific features like temperature control options that suit your product types best.

Citations:

[1] https://www.dryeratech.com/why-every-manufacturer-should-consider-a-hang-type-dryer.html

[2] https://laundrysauce.com/blogs/news/hang-dry-laundry

[3] https://patents.google.com/patent/CN110207480A/zh

[4] https://www.dryeratech.com/the-role-of-hang-type-dryers-in-sustainable-manufacturing-practices.html

[5] https://www.dryeratech.com/hang-type-dryers-for-seafood-processing-benefits-and-best-practices.html

[6] https://pmc.ncbi.nlm.nih.gov/articles/PMC10979823/

[7] https://spirittreefarms.com/hang-drying-clothes-economic-and-environmental-benefits/

[8] https://www.bchydro.com/news/conservation/2019/hang-dry-your-clothes.html