Content Menu

● Introduction to Penetration Type Dryers

● Applications in the Food Industry

>> Drying Fruits

>> Drying Herbs

>> Drying Vegetables

>> Drying Meat Products

● Benefits of Penetration Type Dryers

>> Energy Efficiency

>> Improved Product Quality

>> Environmental Benefits

● Comparison with Other Drying Technologies

>> Direct Drying

>> Indirect Drying

>> Freeze-Drying

● Advanced Features and Innovations

>> Integration with IoT Technology

>> Customization Options

● Case Studies and Success Stories

● Future Developments and Trends

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary benefits of using penetration type dryer machines?

>> 2. How do penetration type dryers compare to traditional drying methods?

>> 3. Can penetration type dryers be used for drying different types of food products?

>> 4. What environmental benefits do penetration type dryers offer?

>> 5. How do penetration type dryers ensure uniform drying?

● Citations:

As the global demand for efficient and sustainable food processing technologies continues to rise, penetration type dryers have emerged as a leading innovation in the field of drying technology. These advanced machines are designed to penetrate heat deeply into food materials, ensuring uniform drying with minimal energy consumption. In this article, we will explore the benefits, applications, and future developments of penetration type dryers, highlighting their role in shaping the future of food drying.

Introduction to Penetration Type Dryers

Penetration type dryers utilize advanced technology to distribute heat evenly throughout the food material, preventing hot spots and ensuring consistent drying results. This is particularly important for sensitive food products that require precise temperature control to preserve their nutritional value and texture.

Key Features of Penetration Type Dryers:

1. Energy Efficiency: These dryers use significantly less electricity compared to traditional models, making them an environmentally friendly option. Some models use only 25% of the electricity required by conventional dryers.

2. Adjustable Temperature: The temperature can be adjusted from 18°C to 80°C, allowing for both hot and cool drying processes. This flexibility is crucial for different types of food products that require specific drying conditions.

3. Uniform Drying: The penetration technology ensures that heat is evenly distributed throughout the material, preventing over-drying or under-drying.

Applications in the Food Industry

Penetration type dryers are versatile and can be used for a variety of food products, including fruits, vegetables, herbs, and even meat products. They are ideal for drying sensitive foods that require precise temperature control to preserve their nutritional value and texture.

Drying Fruits

Drying fruits like strawberries or blueberries requires careful temperature control to maintain their flavor and nutritional content. Penetration type dryers can achieve this by providing a consistent drying environment that prevents over-drying or under-drying.

Drying Herbs

Herbs are delicate and require gentle drying to preserve their aroma and flavor. Penetration type dryers are well-suited for this task, as they can dry herbs at low temperatures, ensuring that their essential oils are retained.

Drying Vegetables

Vegetables can also be dried using penetration type dryers, maintaining their texture and nutritional value. The adjustable temperature settings allow for customization based on the specific drying requirements of each vegetable type.

Drying Meat Products

For meat products, such as beef or chicken jerky, penetration type dryers can provide the precise temperature control needed to ensure food safety while maintaining flavor and texture.

Benefits of Penetration Type Dryers

Energy Efficiency

By using less electricity, penetration type dryers help reduce operational costs and minimize environmental impact. This aligns with global efforts to reduce energy consumption through more efficient technologies.

Improved Product Quality

The controlled drying environment ensures that food products are dried uniformly, which helps maintain their texture and flavor. This is particularly important for products that are sensitive to heat or moisture.

Environmental Benefits

Penetration type dryers contribute to lower greenhouse gas emissions, making them a more sustainable option for food manufacturers. This is achieved by reducing energy consumption and optimizing drying processes.

Comparison with Other Drying Technologies

Direct Drying

Direct drying uses hot air or gas to directly contact the material, providing efficient heat transfer but potentially higher operating costs. This method is less energy-efficient compared to penetration type dryers.

Indirect Drying

Indirect drying keeps the heat source separate from the material, reducing contamination risks but often requiring more complex setups. While it offers advantages in terms of cleanliness, it may not be as efficient as penetration type dryers in terms of energy consumption.

Freeze-Drying

Freeze-drying involves freezing the material and then reducing the surrounding pressure to allow frozen water to sublimate directly into vapor. This method is ideal for preserving nutrients and flavor but can be more expensive and energy-intensive compared to penetration type dryers.

Advanced Features and Innovations

Modern penetration type dryers often include sophisticated temperature control systems that can automatically adjust heating and cooling to optimize drying conditions. Some models incorporate smart sensors that monitor moisture levels and adjust drying times automatically, ensuring optimal drying conditions.

Additionally, some dryers are designed with modular components, allowing for easy upgrades and customization based on specific production needs. This is particularly useful for small-scale producers who may need to adapt their equipment as their business grows.

Integration with IoT Technology

The integration of Internet of Things (IoT) technology in penetration type dryers enables real-time monitoring and remote control. This allows manufacturers to track drying processes from anywhere, ensuring that products meet quality standards and reducing the risk of errors.

Customization Options

Penetration type dryers can be customized to meet specific production needs. For example, they can be designed with different chamber sizes or additional features such as vacuum drying capabilities. This flexibility makes them suitable for a wide range of applications.

Case Studies and Success Stories

Several food manufacturers have successfully integrated penetration type dryers into their production lines, achieving significant cost savings and improvements in product quality. For example, a fruit drying company in Europe reported a 30% reduction in energy costs after switching to penetration type dryers, while also improving the texture and flavor of their dried fruits.

Another case involves a small-scale herb producer who used penetration type dryers to maintain the aroma and flavor of their herbs. The precise temperature control allowed them to produce high-quality dried herbs that met the standards of premium markets.

Future Developments and Trends

As technology continues to evolve, we can expect further innovations in penetration type dryers. Some potential developments include:

1. Advanced Materials: The use of new materials in dryer construction could enhance efficiency and durability.

2. AI Integration: Artificial intelligence could be integrated to predict optimal drying conditions based on real-time data, further improving efficiency and product quality.

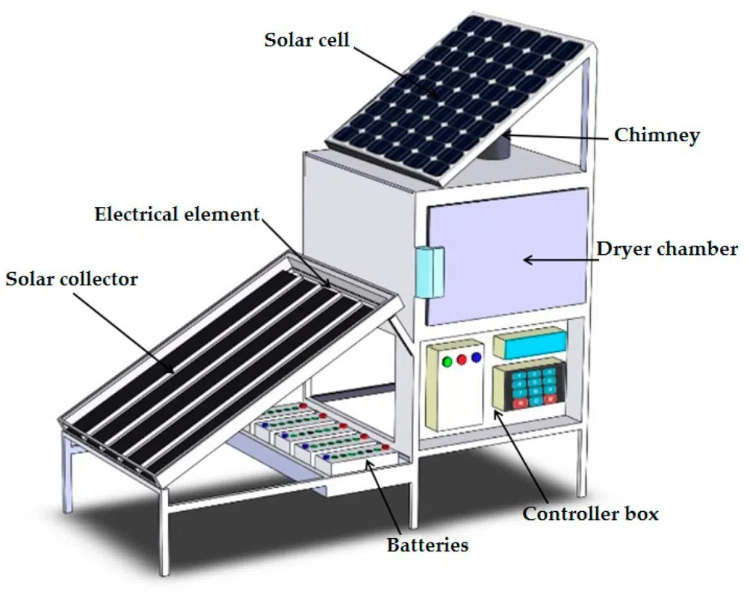

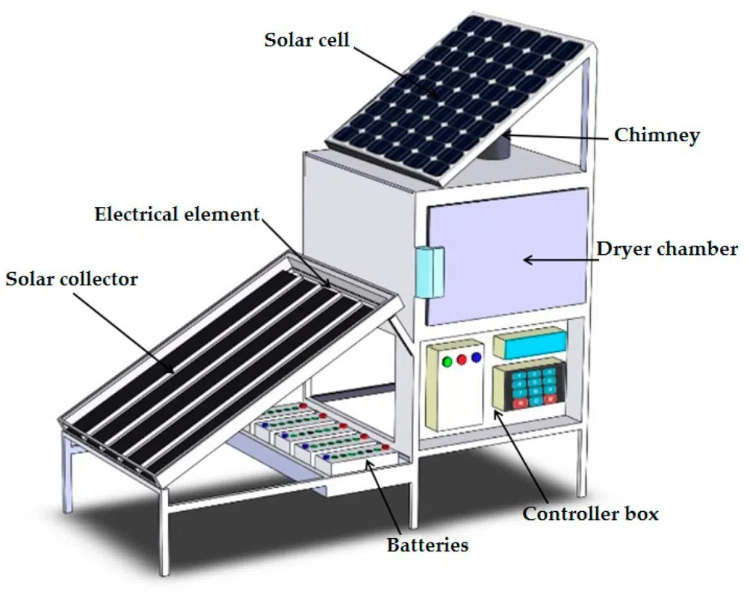

3. Sustainability: Future models may incorporate renewable energy sources or more efficient energy storage systems to reduce environmental impact.

Conclusion

Penetration type dryers offer a compelling solution for food manufacturers seeking efficient, cost-effective drying solutions. Their ability to provide uniform drying with minimal energy consumption makes them an attractive option for a variety of food products. As the demand for sustainable and efficient food processing technologies continues to grow, penetration type dryers are poised to play a significant role in the industry.

Frequently Asked Questions

1. What are the primary benefits of using penetration type dryer machines?

Penetration type dryers offer several benefits, including energy efficiency, improved product quality due to uniform drying, and flexibility in temperature control. These features make them ideal for food manufacturers looking to reduce costs and enhance product quality.

2. How do penetration type dryers compare to traditional drying methods?

Penetration type dryers are more energy-efficient and provide better temperature control compared to traditional drying methods. They use less electricity and can maintain high-quality drying results, making them a more sustainable option.

3. Can penetration type dryers be used for drying different types of food products?

Yes, penetration type dryers are versatile and can be used for a variety of food products, including fruits, vegetables, herbs, and meats. Their adjustable temperature settings allow for customization based on the specific drying requirements of each product.

4. What environmental benefits do penetration type dryers offer?

Penetration type dryers contribute to lower greenhouse gas emissions by reducing energy consumption. This aligns with global efforts to reduce environmental impact through more efficient technologies.

5. How do penetration type dryers ensure uniform drying?

Penetration type dryers use advanced technology to penetrate heat deeply and evenly into the food materials. This ensures that all parts of the product are dried consistently, preventing hot spots and under-drying.

Citations:

[1] https://www.dryeratech.com/understanding-the-benefits-of-penetration-type-dryer-machines.html

[2] https://patents.google.com/patent/CN110207480A/zh

[3] https://www.dryeratech.com/energy-efficiency-the-advantage-of-penetration-type-dryers.html

[4] https://patents.google.com/patent/CN201919616U/zh

[5] https://www.jimdry.com/integrated-stacked-type-dryer.html

[6] https://patents.google.com/patent/WO2022068971A1/zh

[7] https://www.love2laundry.nl/blog/what-is-a-steam-dryer/

[8] https://patents.google.com/patent/CN109252340A/zh