Content Menu

● Introduction

● Understanding Heat Pump Dehydration Dryers

>> How Heat Pump Dehydration Dryers Work

● Applications of Heat Pump Dehydration Dryers

>> 1. Fruit and Vegetable Dehydration

>> 2. Seafood Processing

>> 3. Meat and Poultry Drying

>> 4. Herb and Spice Drying

>> 5. Pet Food Production

● Benefits of Heat Pump Dehydration Dryers

>> 1. Energy Efficiency

>> 2. Precise Temperature and Humidity Control

>> 3. Improved Product Quality

>> 4. Environmentally Friendly

>> 5. Versatility

● Innovations and Future Trends

● Case Studies and Real-World Applications

>> Tomato Dehydration

>> Seafood Processing in Asia

● Conclusion

● Frequently Asked Questions

>> 1. What is the main advantage of using a heat pump dehydration dryer?

>> 2. Can heat pump dehydration dryers be used for all types of food products?

>> 3. How does a heat pump dehydration dryer maintain product quality?

>> 4. Are heat pump dehydration dryers suitable for small-scale operations?

>> 5. How do heat pump dehydration dryers contribute to environmental sustainability?

Introduction

In the ever-evolving world of food preservation and processing, the heat pump dehydration dryer has emerged as a game-changing technology. This innovative device combines the principles of heat pump technology with dehydration processes to create an efficient, cost-effective, and environmentally friendly solution for drying various products, particularly in the food industry. In this comprehensive article, we will explore the intricacies of heat pump dehydration dryers, their applications, benefits, and impact on the food processing industry.

Understanding Heat Pump Dehydration Dryers

A heat pump dehydration dryer is an advanced drying system that utilizes heat pump technology to remove moisture from products while maintaining optimal temperature and humidity levels. This technology offers significant advantages over traditional drying methods, including energy efficiency, precise control over drying conditions, and improved product quality.

The core components of a heat pump dehydration dryer include:

1. Evaporator

2. Compressor

3. Condenser

4. Expansion valve

5. Drying chamber

6. Air circulation system

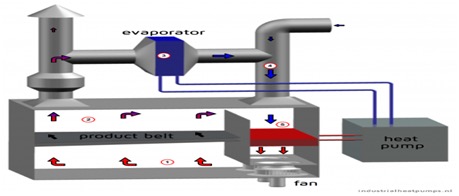

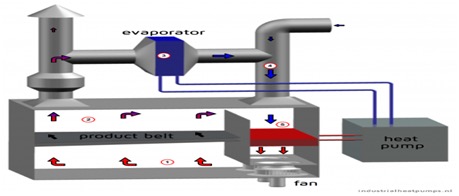

How Heat Pump Dehydration Dryers Work

The working principle of a heat pump dehydration dryer involves a closed-loop system that efficiently transfers heat and removes moisture from the product being dried. Here's a step-by-step breakdown of the process:

1. Warm, moist air from the drying chamber passes through the evaporator, where it is cooled below its dew point.

2. As the air cools, moisture condenses and is collected as water.

3. The now-cooled and dehumidified air moves to the condenser, where it is reheated.

4. The heated, dry air is then circulated back into the drying chamber to continue the drying process.

5. This cycle repeats until the desired moisture content in the product is achieved.

Applications of Heat Pump Dehydration Dryers

Heat pump dehydration dryers have found widespread applications across various industries, with a particular focus on food processing and preservation. Some key applications include:

1. Fruit and Vegetable Dehydration

Heat pump dryers are excellent for preserving fruits and vegetables while maintaining their nutritional value, color, and flavor. They are particularly effective for drying sensitive products like berries, herbs, and leafy greens.

2. Seafood Processing

The heat pump dehydration dryer is ideal for drying various seafood products, including fish, shrimp, and squid. It helps preserve the delicate flavors and textures of seafood while extending shelf life.

3. Meat and Poultry Drying

For producing dried meats, jerky, and other preserved meat products, heat pump dehydration dryers offer precise control over temperature and humidity, ensuring food safety and quality.

4. Herb and Spice Drying

The gentle drying process of heat pump dehydration dryers is perfect for preserving the essential oils and flavors of herbs and spices.

5. Pet Food Production

Heat pump dryers are increasingly used in the production of dried pet foods, offering energy-efficient drying while maintaining nutritional value.

Benefits of Heat Pump Dehydration Dryers

The adoption of heat pump dehydration dryers offers numerous advantages over conventional drying methods:

1. Energy Efficiency

Heat pump dryers are highly energy-efficient, consuming up to 60-70% less energy compared to traditional hot air dryers. This efficiency translates to significant cost savings and reduced environmental impact.

2. Precise Temperature and Humidity Control

The ability to maintain consistent and controllable drying conditions ensures optimal product quality and reduces the risk of over-drying or under-drying.

3. Improved Product Quality

The gentle drying process preserves the nutritional content, color, flavor, and texture of dried products, resulting in higher-quality end products.

4. Environmentally Friendly

With lower energy consumption and the potential for integration with renewable energy sources, heat pump dehydration dryers contribute to reduced carbon emissions and environmental sustainability.

5. Versatility

These dryers can handle a wide range of products and can be easily adjusted to accommodate different drying requirements.

Innovations and Future Trends

The field of heat pump dehydration drying continues to evolve, with ongoing research and development focusing on:

1. Integration of smart technologies for improved process control and monitoring

2. Hybrid systems combining heat pump technology with other drying methods

3. Development of more compact and efficient heat pump components

4. Exploration of new applications in pharmaceuticals and biomaterials

Case Studies and Real-World Applications

To illustrate the effectiveness of heat pump dehydration dryers, let's look at some real-world applications:

Tomato Dehydration

A study on tomato dehydration using a heat pump dryer demonstrated significant energy savings and improved product quality compared to conventional drying methods.

Seafood Processing in Asia

Many seafood processing facilities in Southeast Asia have adopted heat pump dehydration dryers to improve the quality and shelf life of dried fish and shrimp products while reducing energy costs.

Conclusion

Heat pump dehydration dryers represent a significant advancement in drying technology, offering a perfect balance of energy efficiency, product quality, and environmental sustainability. As the food processing industry continues to seek innovative solutions to meet growing demand and stringent quality standards, heat pump dehydration dryers are poised to play an increasingly important role in shaping the future of food preservation and processing.

Frequently Asked Questions

1. What is the main advantage of using a heat pump dehydration dryer?

Answer: The main advantage of using a heat pump dehydration dryer is its high energy efficiency. These dryers can consume up to 60-70% less energy compared to traditional hot air dryers, resulting in significant cost savings and reduced environmental impact.

2. Can heat pump dehydration dryers be used for all types of food products?

Answer: While heat pump dehydration dryers are versatile and can be used for a wide range of food products, they are particularly effective for drying fruits, vegetables, herbs, seafood, and meat products. However, the specific drying parameters may need to be adjusted for different types of food to achieve optimal results.

3. How does a heat pump dehydration dryer maintain product quality?

Answer: Heat pump dehydration dryers maintain product quality by providing precise control over temperature and humidity levels during the drying process. This gentle drying method helps preserve the nutritional content, color, flavor, and texture of the dried products, resulting in higher-quality end products compared to conventional drying methods.

4. Are heat pump dehydration dryers suitable for small-scale operations?

Answer: Yes, heat pump dehydration dryers are available in various sizes and capacities, making them suitable for both small-scale and large-scale operations. Smaller units can be used for artisanal food production or research purposes, while larger industrial-scale units are available for high-volume processing.

5. How do heat pump dehydration dryers contribute to environmental sustainability?

Answer: Heat pump dehydration dryers contribute to environmental sustainability in several ways:

1. They consume significantly less energy than conventional dryers, reducing overall energy consumption and associated carbon emissions.

2. The closed-loop system recycles heat, minimizing waste energy.

3. They can be integrated with renewable energy sources, further reducing their environmental impact.

4. The precise control over drying conditions reduces the likelihood of product waste due to over-drying or under-drying.