Content Menu

● Introduction to Drying Technologies

>> Types of Drying Technologies

● Material Properties and Drying

>> Porosity and Moisture Content

>> Heat Sensitivity

>> Glass Transition Temperature

● Designing Dryers Based on Material Properties

>> Airflow Configuration

>> Temperature Control

>> Material Handling

● Advanced Drying Technologies

>> Infrared Drying

>> Ultrasonic Drying

>> Hybrid Drying Systems

● Economic and Environmental Considerations

>> Energy Efficiency

>> Sustainability

● Conclusion

● Frequently Asked Questions

>> 1. How Does Porosity Affect Drying?

>> 2. What Role Does Glass Transition Temperature Play in Drying?

>> 3. How Does Heat Sensitivity Impact Drying Method Choice?

>> 4. What Are the Key Factors in Designing a Dryer?

>> 5. How Does Airflow Direction Affect Drying Efficiency?

● Citations:

In the realm of food drying, the selection of an appropriate dryer is crucial for maintaining product quality, ensuring efficient drying processes, and optimizing energy consumption. Material properties play a pivotal role in this decision-making process, as they directly influence how a material responds to different drying conditions. This article delves into the significance of material properties in choosing the right dryer for food products, exploring various drying technologies and their applications.

Introduction to Drying Technologies

Drying is a fundamental process in food preservation, aimed at reducing moisture content to prevent spoilage and extend shelf life. The choice of drying technology depends on several factors, including the type of food material, its moisture content, heat sensitivity, and desired final product quality.

Types of Drying Technologies

1. Hot Air Drying (HAD): This is one of the most common methods, where hot air is circulated around the food material to evaporate moisture. It is widely used due to its simplicity and cost-effectiveness.

2. Microwave Drying (MD): This method uses microwave energy to heat the water molecules within the food, leading to rapid evaporation. It is beneficial for materials that are sensitive to high temperatures.

3. Vacuum Drying (VD): Conducted under reduced pressure, this method allows for drying at lower temperatures, preserving the nutritional and sensory qualities of food.

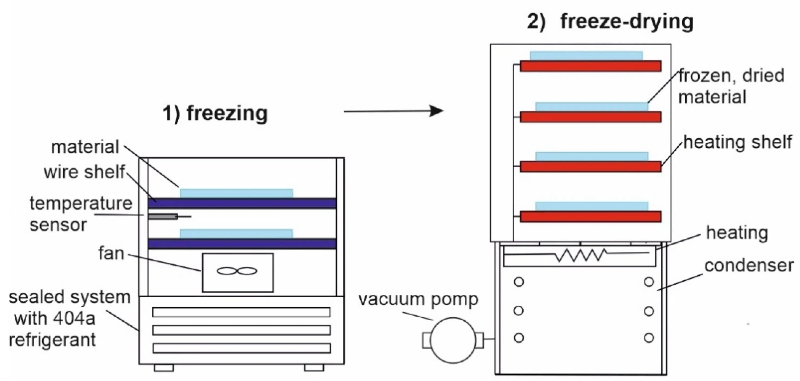

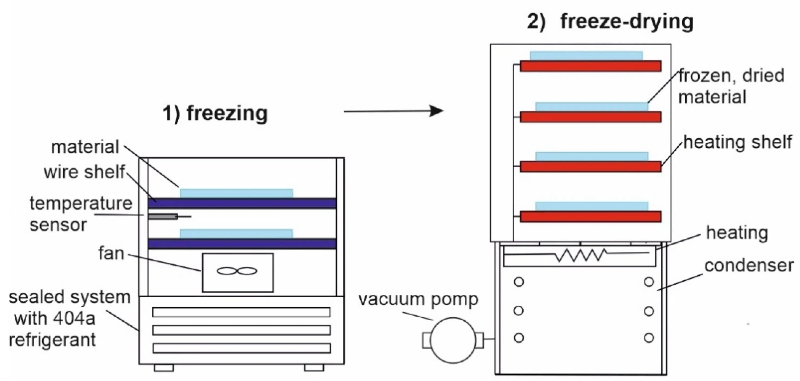

4. Vacuum Freeze Drying (VFD): A combination of freezing and vacuum drying, this method is ideal for preserving delicate food structures and flavors.

Material Properties and Drying

Material properties such as porosity, moisture content, and heat sensitivity significantly affect the drying process. Understanding these properties helps in selecting the most suitable drying technology.

Porosity and Moisture Content

- Porous Materials: These materials have high initial moisture content and undergo significant volume changes during drying, leading to shrinkage. The type of porosity (microporous, mesoporous, macroporous) influences the rate of moisture removal and potential structural changes.

- Moisture Content: Higher moisture content requires more energy for drying. The initial moisture content also affects the choice of drying method, as some methods are more efficient for materials with high moisture levels.

Heat Sensitivity

- Thermal Stability: Materials with low thermal stability require drying methods that operate at lower temperatures to prevent degradation. Vacuum drying and freeze drying are often preferred for such materials.

Glass Transition Temperature

- Glass Transition Temperature (Tg): This is critical in drying processes, especially for materials that undergo a transition from a rubbery to a glassy state. Maintaining the material above or below Tg can affect its texture and stability.

Designing Dryers Based on Material Properties

The design of a dryer must consider the specific properties of the material being dried. Factors such as airflow configuration, temperature control, and material handling are crucial for optimizing the drying process.

Airflow Configuration

- Co-Current vs. Counter-Current: The direction of airflow relative to the material flow affects drying efficiency. Co-current dryers are suitable for materials with high surface moisture, while counter-current dryers are better for materials that require more uniform drying.

Temperature Control

- Temperature Profiles: Maintaining optimal temperature profiles is essential to prevent overheating or underheating, which can lead to product degradation or incomplete drying.

Material Handling

- Material Flow: Ensuring consistent material flow through the dryer is vital for uniform drying. This involves considering factors like particle size and flowability.

Advanced Drying Technologies

In addition to traditional drying methods, advanced technologies are being developed to improve efficiency and product quality.

Infrared Drying

- Infrared Radiation: This method uses infrared radiation to heat the material directly, reducing drying time and improving energy efficiency.

Ultrasonic Drying

- Ultrasonic Waves: This innovative method employs ultrasonic waves to enhance moisture removal, especially useful for materials with low thermal conductivity.

Hybrid Drying Systems

- Combination of Methods: Some systems combine different drying methods (e.g., hot air and microwave) to leverage the advantages of each, offering improved flexibility and efficiency.

Economic and Environmental Considerations

The choice of dryer also involves economic and environmental factors, such as energy consumption and waste management.

Energy Efficiency

- Energy Consumption: Dryers with high energy efficiency reduce operational costs and environmental impact. Technologies like infrared and ultrasonic drying are being explored for their potential to lower energy consumption.

Sustainability

- Sustainable Practices: Adopting sustainable drying practices, such as using renewable energy sources and minimizing waste, is increasingly important for environmentally conscious manufacturers.

Conclusion

The choice of dryer for food products is heavily influenced by the material properties of the food. Understanding these properties allows for the selection of the most appropriate drying technology, ensuring efficient drying processes and high-quality final products. By considering factors such as porosity, moisture content, heat sensitivity, and glass transition temperature, manufacturers can optimize their drying operations to meet specific product requirements.

Frequently Asked Questions

1. How Does Porosity Affect Drying?

Answer: Porosity affects drying by influencing the rate of moisture removal. Materials with larger pores tend to dry faster but may experience more significant shrinkage, while those with smaller pores dry more slowly with less shrinkage.

2. What Role Does Glass Transition Temperature Play in Drying?

Answer: The glass transition temperature (Tg) is crucial in drying as it determines the state of the material (rubbery or glassy), affecting its texture and stability. Maintaining the material above or below Tg can prevent unwanted changes.

3. How Does Heat Sensitivity Impact Drying Method Choice?

Answer: Heat-sensitive materials require drying methods that operate at lower temperatures to prevent degradation. Techniques like vacuum drying and freeze drying are often used for such materials.

4. What Are the Key Factors in Designing a Dryer?

Answer: Key factors include airflow configuration, temperature control, and material handling. These elements must be tailored to the specific properties of the material being dried to optimize the drying process.

5. How Does Airflow Direction Affect Drying Efficiency?

Answer: The direction of airflow (co-current or counter-current) affects drying efficiency by influencing how moisture is removed from the material. Co-current dryers are better for materials with high surface moisture, while counter-current dryers provide more uniform drying.

Citations:

[1] https://www.frontiersin.org/journals/materials/articles/10.3389/fmats.2024.1330599/full

[2] https://dryershub.com/clothes-dryer/parts/dryer-drum-material/

[3] http://m.mofcom.gov.cn/article/ckzn/upload/yangrzp2018.pdf

[4] https://earthwormexpress.com/wp-content/uploads/2021/06/Quality-Changes-in-Food-Materials-as-Influenced-by-Drying-Processes.pdf

[5] https://blog.kason.com/blog/dryer-design-choosing-the-right-drying-technology-for-your-application

[6] https://pmc.ncbi.nlm.nih.gov/articles/PMC10534175/

[7] https://feeco.com/co-current-vs-counter-current-drying/

[8] https://ifst.onlinelibrary.wiley.com/doi/10.1111/ijfs.16043