Content Menu

● Introduction

● The Evolution of Food Dehydrator Design

● Key Elements of User-Friendly Design in Food Dehydrators

>> Intuitive Controls

>> Ergonomic Considerations

>> Clear Visual Indicators

>> Modular Design

● The Impact of User-Friendly Design on Industrial Processes

>> Increased Efficiency

>> Reduced Error Rates

>> Enhanced Safety

>> Improved Product Quality

● Case Studies: User-Friendly Design in Action

>> Excalibur Dehydrator

>> COSORI Food Dehydrator

● The Role of User-Centered Design in Industrial Automation

>> Human-Machine Interface (HMI) Design

>> Addressing Environmental Challenges

● The Future of User-Friendly Design in Food Dehydration

>> Integration of Smart Technology

>> Artificial Intelligence and Machine Learning

>> Augmented Reality Interfaces

● The Importance of User Testing and Feedback

● Sustainability and User-Friendly Design

>> Energy Efficiency

>> Reduced Food Waste

>> Longevity and Repairability

● Training and Skill Development

>> Reduced Training Time

>> Enhanced Operator Confidence

>> Continuous Learning

● Conclusion

● FAQ

>> 1. Why is user-friendly design important in industrial food dehydrators?

>> 2. What are some key features of a user-friendly food dehydrator?

>> 3. How does user-friendly design impact food quality in dehydration processes?

>> 4. Can user-friendly design in food dehydrators lead to cost savings?

>> 5. What future developments can we expect in user-friendly design for food dehydrators?

● Citations:

Introduction

In the ever-evolving landscape of industrial equipment, the importance of user-friendly design cannot be overstated. This is particularly true in the food processing industry, where efficiency, safety, and ease of use are paramount. Food dehydrators, essential tools in food preservation and production, serve as an excellent example of how user-friendly design can significantly impact industrial processes. This article explores the critical role of user-centric design in food dehydrators, highlighting its benefits and showcasing how it enhances productivity and user satisfaction in industrial settings.

The Evolution of Food Dehydrator Design

Food dehydration has been a preservation method for centuries, but modern technology has transformed this ancient practice into a sophisticated industrial process. Today's food dehydrators are a far cry from the simple sun-drying methods of the past. They incorporate advanced features and user-friendly interfaces that make the dehydration process more efficient and accessible.

The evolution of food dehydrator design reflects a broader trend in industrial equipment: the move towards more intuitive, user-centered interfaces. This shift recognizes that even in industrial settings, the human element is crucial. Operators who can easily understand and control their equipment are more productive, make fewer errors, and contribute to a safer work environment.

Key Elements of User-Friendly Design in Food Dehydrators

Intuitive Controls

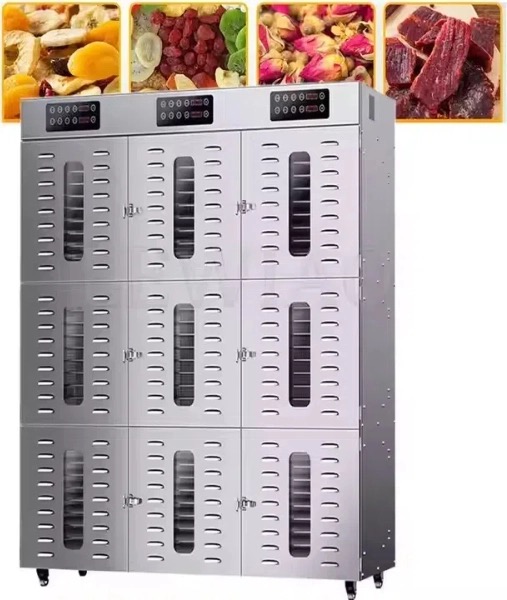

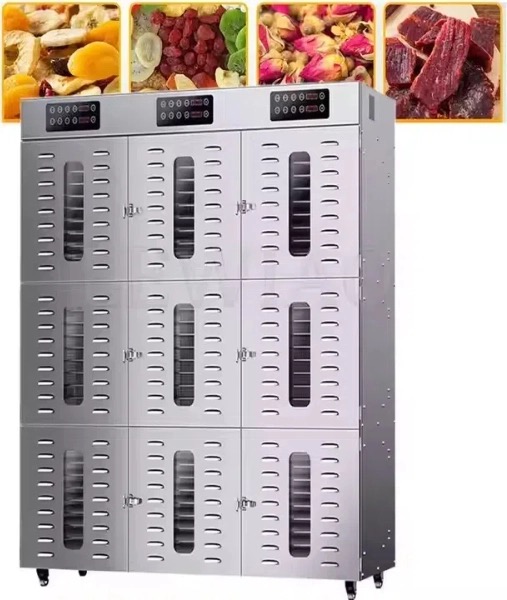

One of the most critical aspects of user-friendly design in food dehydrators is the implementation of intuitive controls. Modern dehydrators often feature digital interfaces with clear, easy-to-read displays and straightforward button layouts. These interfaces allow operators to set precise temperatures and drying times with minimal effort, reducing the learning curve and potential for errors.

Ergonomic Considerations

Ergonomics plays a vital role in the design of industrial food dehydrators. Considerations such as the height of the machine, the placement of controls, and the ease of loading and unloading trays all contribute to a more comfortable and efficient user experience. Well-designed dehydrators minimize physical strain on operators, reducing fatigue and the risk of repetitive strain injuries.

Clear Visual Indicators

User-friendly food dehydrators often incorporate clear visual indicators that provide at-a-glance information about the dehydration process. These may include LED lights that show when the machine is in operation, progress bars that indicate remaining drying time, or color-coded displays that signal different stages of the process. Such features enable operators to monitor the dehydration process easily, even from a distance.

Modular Design

Many modern food dehydrators feature modular designs that allow for easy cleaning and maintenance. Removable trays, accessible filters, and detachable components not only simplify the cleaning process but also make it easier for operators to perform routine maintenance tasks. This modular approach extends the life of the equipment and ensures consistent performance over time.

The Impact of User-Friendly Design on Industrial Processes

Increased Efficiency

User-friendly design in food dehydrators translates directly into increased operational efficiency. When operators can quickly and accurately set up and monitor the dehydration process, it reduces downtime and improves overall productivity. For example, the COSORI Food Dehydrator, known for its intuitive design, has been praised for its ability to streamline the dehydration process, allowing for more consistent results and faster turnaround times.

Reduced Error Rates

Complex interfaces and confusing controls can lead to operator errors, resulting in wasted resources and subpar products. User-friendly designs minimize these risks by making it easier for operators to input correct settings and monitor the dehydration process accurately. This reduction in errors not only improves product quality but also contributes to cost savings by reducing waste.

Enhanced Safety

Safety is a paramount concern in any industrial setting, and user-friendly design plays a crucial role in maintaining a safe work environment. Dehydrators with clear, easy-to-understand controls and safety features reduce the risk of accidents and injuries. For instance, automatic shut-off features and clear warning indicators help prevent overheating or other potential hazards.

Improved Product Quality

When operators can easily control and fine-tune the dehydration process, it leads to better product quality. User-friendly interfaces allow for precise temperature and time settings, ensuring that foods are dehydrated to the exact specifications required. This level of control is essential for maintaining consistent quality across batches and meeting stringent food safety standards.

Case Studies: User-Friendly Design in Action

Excalibur Dehydrator

The Excalibur dehydrator is renowned for its user-friendly design features. It incorporates a transparent door, allowing users to monitor the drying process without interrupting it. The analog knobs for time and temperature settings provide tactile feedback and are easy to adjust, even for operators wearing gloves. These design elements contribute to a more intuitive and efficient dehydration process.

COSORI Food Dehydrator

The COSORI Food Dehydrator exemplifies how user-friendly design can enhance industrial food processing. Its sleek design includes handles for easy carrying and a magnetic hinging door for seamless operation. The digital interface equipped with a timer and temperature setting allows for precise control, while its quiet operation and easy-to-clean components make it a favorite among users.

The Role of User-Centered Design in Industrial Automation

The principles of user-friendly design extend beyond individual machines to encompass entire industrial automation systems. In the context of food dehydration, this might involve integrating dehydrators into larger production lines or implementing centralized control systems that manage multiple units simultaneously.

Human-Machine Interface (HMI) Design

Human-Machine Interfaces (HMIs) are critical components in industrial automation, serving as the primary point of interaction between operators and equipment. In food dehydration facilities, well-designed HMIs can significantly enhance operational efficiency and user satisfaction. Key considerations in HMI design for food dehydrators include:

- Clear visual representations of the dehydration process

- Intuitive navigation between different control screens

- Real-time data displays for temperature, humidity, and drying progress

- Easy access to historical data and performance metrics

Addressing Environmental Challenges

Industrial environments often present unique challenges that must be addressed in the design of user interfaces. For food dehydrators, these might include:

- Designing interfaces that are easily readable in varying light conditions

- Ensuring controls can be operated while wearing protective gear such as gloves

- Creating interfaces that are resistant to moisture and food debris

- Implementing audible alerts or large visual indicators for noisy environments

By addressing these environmental factors, designers can create interfaces that are not only user-friendly but also robust and reliable in industrial settings.

The Future of User-Friendly Design in Food Dehydration

As technology continues to advance, the future of user-friendly design in food dehydrators looks promising. Some emerging trends include:

Integration of Smart Technology

Future food dehydrators may incorporate smart technology, allowing for remote monitoring and control via mobile devices. This could enable operators to adjust settings, receive alerts, and track dehydration progress from anywhere in the facility or even off-site.

Artificial Intelligence and Machine Learning

AI and machine learning algorithms could be integrated into food dehydrators to optimize drying cycles based on specific food types and desired outcomes. These systems could learn from past operations to suggest ideal settings and predict maintenance needs.

Augmented Reality Interfaces

Augmented reality (AR) could revolutionize how operators interact with food dehydrators. AR overlays could provide real-time information about the dehydration process, guide maintenance procedures, or offer training for new operators.

The Importance of User Testing and Feedback

Developing truly user-friendly designs for industrial food dehydrators requires ongoing user testing and feedback. Manufacturers must engage with operators, maintenance personnel, and other stakeholders to understand their needs and challenges. This iterative process of design, testing, and refinement is crucial for creating equipment that not only performs well technically but also enhances the user experience.

Sustainability and User-Friendly Design

An often overlooked aspect of user-friendly design in industrial equipment is its potential impact on sustainability. Well-designed food dehydrators can contribute to more sustainable food processing practices in several ways:

Energy Efficiency

User-friendly interfaces that allow for precise control of temperature and drying times can lead to more energy-efficient operations. When operators can easily optimize settings for different food types and quantities, it reduces unnecessary energy consumption and contributes to lower operational costs and reduced environmental impact.

Reduced Food Waste

Intuitive controls and clear monitoring systems help prevent over-drying or under-drying of food products. This precision leads to higher quality output and less food waste, aligning with global efforts to reduce food loss in processing and manufacturing.

Longevity and Repairability

Food dehydrators designed with user-friendly maintenance features tend to have longer operational lifespans. Easy-to-clean components, accessible parts for repairs, and modular designs not only make the equipment more user-friendly but also more sustainable by reducing the frequency of replacements and the associated environmental costs of manufacturing new machines.

Training and Skill Development

The implementation of user-friendly design in food dehydrators has significant implications for operator training and skill development:

Reduced Training Time

Intuitive interfaces and controls can significantly reduce the time required to train new operators. This not only improves operational efficiency but also makes it easier for companies to scale their workforce as needed.

Enhanced Operator Confidence

When operators feel confident in their ability to use equipment effectively, it leads to improved job satisfaction and performance. User-friendly designs contribute to this confidence by reducing the likelihood of errors and providing clear feedback on machine operations.

Continuous Learning

Advanced user interfaces can incorporate built-in tutorials or help functions, facilitating continuous learning and skill development for operators. This ongoing education can lead to more knowledgeable staff and improved overall operational performance.

Conclusion

The importance of user-friendly design in industrial equipment, particularly in food dehydrators, cannot be overstated. As we have explored throughout this article, user-centric design principles lead to increased efficiency, reduced errors, enhanced safety, and improved product quality. By prioritizing intuitive controls, ergonomic considerations, clear visual indicators, and modular designs, manufacturers can create food dehydrators that not only meet the technical requirements of industrial food processing but also enhance the overall user experience.

As the food processing industry continues to evolve, the role of user-friendly design will only grow in importance. The integration of smart technologies, AI, and augmented reality promises to further revolutionize how operators interact with food dehydrators and other industrial equipment. By staying focused on the needs and experiences of end-users, manufacturers can ensure that their equipment remains at the forefront of innovation and productivity in the industrial food processing sector.

The future of food dehydration lies not just in technological advancements, but in the thoughtful application of these technologies to create equipment that is both powerful and accessible. As we move forward, the most successful industrial food dehydrators will be those that seamlessly blend cutting-edge technology with intuitive, user-friendly designs, ultimately leading to more efficient, safer, and more productive food processing operations.

FAQ

1. Why is user-friendly design important in industrial food dehydrators?

User-friendly design in industrial food dehydrators is crucial because it enhances operational efficiency, reduces errors, improves safety, and contributes to better product quality. When operators can easily understand and control the equipment, they can work more productively and with fewer mistakes, leading to improved overall performance in food processing facilities.

2. What are some key features of a user-friendly food dehydrator?

Key features of a user-friendly food dehydrator include intuitive digital interfaces, clear visual indicators, ergonomic design for easy loading and unloading, modular components for simple cleaning and maintenance, and precise temperature and time controls. Additionally, features like transparent doors for easy monitoring and quiet operation contribute to a better user experience.

3. How does user-friendly design impact food quality in dehydration processes?

User-friendly design positively impacts food quality by allowing operators to set precise temperature and time parameters easily. This level of control ensures that foods are dehydrated to exact specifications, maintaining consistent quality across batches. It also reduces the risk of over-drying or under-drying, which can affect the texture, flavor, and nutritional value of the final product.

4. Can user-friendly design in food dehydrators lead to cost savings?

Yes, user-friendly design in food dehydrators can lead to significant cost savings. By reducing operator errors, minimizing downtime for training or troubleshooting, and improving overall efficiency, user-friendly dehydrators can increase productivity and reduce waste. Additionally, features that simplify cleaning and maintenance can extend the equipment's lifespan, providing long-term cost benefits.

5. What future developments can we expect in user-friendly design for food dehydrators?

Future developments in user-friendly design for food dehydrators may include integration with smart technologies for remote monitoring and control, incorporation of AI and machine learning for optimized drying cycles, and the use of augmented reality interfaces for enhanced operator guidance and training. These advancements will further improve ease of use, efficiency, and overall performance of industrial food dehydrators.

Citations:

[1] https://www.automate.org/blogs/simplifying-the-complex-the-role-of-ui-ux-in-industrial-automation

[2] https://www.verfoodsolutions.com/products/vegetable-process/air-cooling-drying-machine/parallel-air-drying-machine/

[3] https://www.cadcrowd.com/blog/key-benefits-of-industrial-product-design-using-industrial-product-design-services/

[4] https://www.seriouseats.com/best-food-dehydrators-5216308

[5] https://www.youtube.com/watch?v=iIuV3EkRFtU

[6] https://www.uxmatters.com/mt/archives/2017/08/ux-for-the-industrial-environment-part-1.php

[7] https://artversion.com/blog/user-centered-approach-to-interface-design-for-heavy-equipment-manufacturing/

[8] https://www.youtube.com/watch?v=lEUA2t2XD5M

[9] https://ux.stackexchange.com/questions/7470/recommended-best-practices-for-industrial-interface-design

[10] https://dienamics.com.au/blog/how-industrial-design-improves-user-experience/

[11] https://oxd.com/insights/the-pivotal-role-of-user-interface-and-user-experience-in-industrial-manufacturing/

[12] https://www.automationworld.com/design/article/21119745/the-benefits-of-user-experience-and-interfaces-in-an-industrial-process

[13] https://www.foodandwine.com/lifestyle/kitchen/best-food-dehydrators

[14] https://blog.biamp.com/dont-overlook-the-benefits-of-good-industrial-design/

[15] https://www.istockphoto.com/photos/food-dryer

[16] https://www.istockphoto.com/photos/food-dehydrator

[17] https://www.youtube.com/watch?v=Zl4wTcCPJu0

[18] https://stock.adobe.com/search?k=industrial+design

[19] https://stock.adobe.com/search?k=dehydrator