Content Menu

● Introduction to Drum Drying Technology

● Understanding the Food Drum Drying Machine

>> Key Components of a Food Drum Drying Machine

● The Drum Drying Process: From Liquid to Powder

● Applications of Food Drum Drying Machines

>> 1. Dairy Products

>> 2. Fruit and Vegetable Purees

>> 3. Starch-based Products

>> 4. Pet Food Ingredients

>> 5. Nutraceuticals and Functional Foods

● Advantages of Using Food Drum Drying Machines

>> 1. Energy Efficiency

>> 2. Product Quality

>> 3. Versatility

>> 4. Continuous Operation

>> 5. Hygienic Processing

● Innovations in Drum Drying Technology

>> 1. Multi-drum Systems

>> 2. Vacuum Drum Dryers

>> 3. Intelligent Control Systems

● Comparing Drum Drying to Other Drying Methods

>> Drum Drying vs. Spray Drying

>> Drum Drying vs. Freeze Drying

● The Future of Food Drum Drying Machines

● Conclusion

● Frequently Asked Questions

>> Q1: What types of foods can be processed using a food drum drying machine?

>> Q2: How does drum drying affect the nutritional value of food?

>> Q3: Are food drum drying machines energy-efficient?

>> Q4: How does the quality of drum-dried products compare to freeze-dried products?

>> Q5: What are the main advantages of using a food drum drying machine in food processing?

Introduction to Drum Drying Technology

In the ever-evolving world of food processing, one technology stands out for its efficiency and versatility: the food drum drying machine. This innovative piece of equipment has revolutionized the way we transform liquid and semi-liquid foods into shelf-stable powders, opening up new possibilities for food preservation and product development.

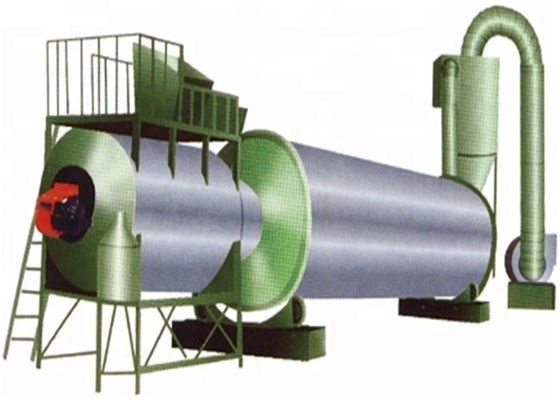

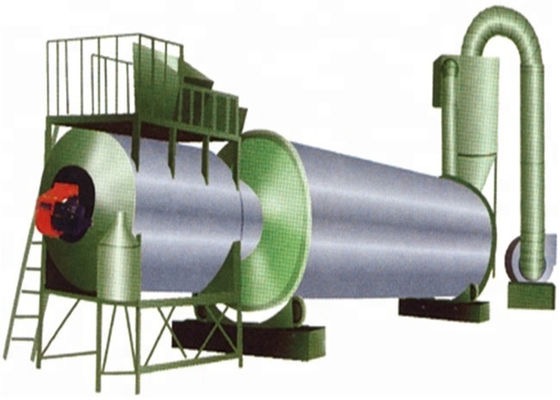

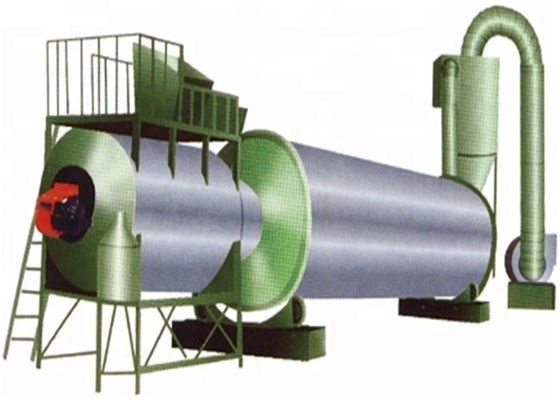

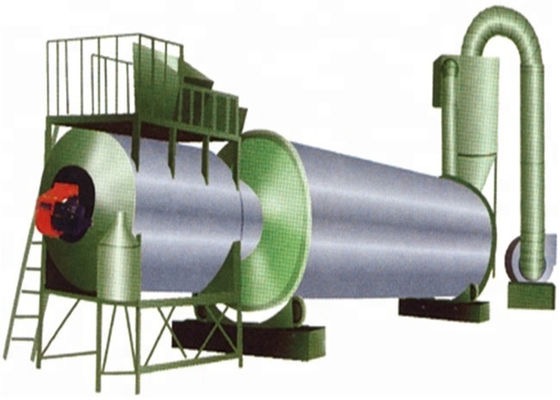

Understanding the Food Drum Drying Machine

A food drum drying machine is a sophisticated piece of industrial food processing equipment designed to remove moisture from liquid or pureed foods. The process involves spreading the food material thinly over the surface of a rotating heated drum. As the drum turns, the food is exposed to hot air, which rapidly evaporates the moisture, leaving behind a dry, powdered product.

Key Components of a Food Drum Drying Machine

1. Drying drum: The heart of the machine, typically made of stainless steel and polished to food-grade standards.

2. Heating element: Provides the necessary heat for moisture evaporation.

3. Rotating shaft and blades: Ensures even distribution of the food material on the drum surface.

4. Drying chamber: Encloses the drum and maintains optimal drying conditions.

5. Scraper blade: Removes the dried product from the drum surface.

The Drum Drying Process: From Liquid to Powder

The drum drying process is a marvel of engineering that efficiently converts liquid foods into powders. Here's a step-by-step breakdown of how a food drum drying machine works:

1. Feeding: The liquid or pureed food is fed onto the rotating drum.

2. Spreading: As the drum rotates, the food forms a thin, even layer on its surface.

3. Heating: The drum's surface is heated, typically by steam, to temperatures between 120°C and 170°C.

4. Evaporation: Moisture rapidly evaporates from the food as it comes into contact with the hot drum surface.

5. Drying: The food continues to dry as it rotates with the drum.

6. Scraping: A blade scrapes off the dried food in the form of a thin sheet or flakes.

7. Collection: The dried product is collected and may be further processed into a powder.

Applications of Food Drum Drying Machines

The versatility of food drum drying machines makes them indispensable in various sectors of the food industry. Some common applications include:

1. Dairy Products

Drum dryers are extensively used in the dairy industry to produce powdered milk, cheese powders, and other dairy-based ingredients. The process helps extend the shelf life of dairy products while maintaining their nutritional value.

2. Fruit and Vegetable Purees

Fruit and vegetable purees can be transformed into powders using drum drying technology. These powders are used in instant soups, baby foods, and as natural food colorants.

3. Starch-based Products

Drum dryers are ideal for processing starchy slurries into instant flours, pre-gelatinized starches, and other modified starch products used in various food applications.

4. Pet Food Ingredients

The pet food industry utilizes drum-dried ingredients to create nutritious and palatable dry pet foods.

5. Nutraceuticals and Functional Foods

Drum drying is employed in the production of powdered supplements and functional food ingredients, preserving the active compounds while improving stability and solubility.

Advantages of Using Food Drum Drying Machines

The popularity of food drum drying machines in industrial food processing can be attributed to several key advantages:

1. Energy Efficiency

Drum drying is one of the most energy-efficient drying methods available. The direct contact between the product and the heated surface ensures rapid heat transfer and moisture removal, reducing overall energy consumption.

2. Product Quality

The quick drying process helps retain the nutritional value, color, and flavor of the original food material. This is particularly important for heat-sensitive ingredients.

3. Versatility

Food drum drying machines can handle a wide range of viscosities, from thin liquids to thick pastes, making them suitable for various food products.

4. Continuous Operation

These machines are designed for continuous operation, allowing for high-volume production with minimal downtime.

5. Hygienic Processing

The smooth, polished surfaces of drum dryers are easy to clean and maintain, ensuring hygienic food processing conditions.

Innovations in Drum Drying Technology

As the food industry continues to evolve, so does drum drying technology. Recent innovations include:

1. Multi-drum Systems

These systems use multiple drums in series or parallel to increase production capacity and allow for different drying conditions within a single process.

2. Vacuum Drum Dryers

By operating under vacuum conditions, these dryers can process heat-sensitive materials at lower temperatures, preserving delicate flavors and nutrients.

3. Intelligent Control Systems

Advanced control systems with real-time monitoring capabilities optimize the drying process, ensuring consistent product quality and maximizing energy efficiency.

Comparing Drum Drying to Other Drying Methods

While drum drying is highly effective for many applications, it's essential to understand how it compares to other drying methods:

Drum Drying vs. Spray Drying

Spray drying is another popular method for producing food powders. While spray drying can handle larger volumes and is suitable for heat-sensitive materials, drum drying is more energy-efficient and better suited for viscous products.

Drum Drying vs. Freeze Drying

Freeze drying produces high-quality products with excellent rehydration properties but is more expensive and time-consuming than drum drying. Drum drying is more suitable for large-scale production of less delicate products.

The Future of Food Drum Drying Machines

As the global demand for convenient, shelf-stable food products continues to grow, the importance of food drum drying machines in industrial food processing is set to increase. Future developments may focus on:

1. Improved energy efficiency through advanced heat recovery systems

2. Enhanced automation and Industry 4.0 integration

3. Development of novel drum surface materials for better heat transfer and product release

4. Expansion into new food categories and non-food applications

Conclusion

Food drum drying machines have become an integral part of modern food processing, offering an efficient and versatile solution for converting liquid foods into shelf-stable powders. As technology continues to advance, these machines will play an increasingly important role in meeting the world's growing demand for high-quality, convenient food products.

Frequently Asked Questions

Q1: What types of foods can be processed using a food drum drying machine?

A1: Food drum drying machines can process a wide variety of foods, including dairy products (milk, cheese), fruit and vegetable purees, starchy slurries, and even some meat-based products. They are particularly well-suited for viscous liquids and pastes.

Q2: How does drum drying affect the nutritional value of food?

A2: While some heat-sensitive vitamins may be affected, drum drying generally preserves most of the nutritional value of the original food. The rapid drying process helps retain many nutrients, and the powder form can actually increase the bioavailability of certain compounds.

Q3: Are food drum drying machines energy-efficient?

A3: Yes, food drum drying machines are considered one of the most energy-efficient drying methods in the food industry. The direct contact between the product and the heated drum surface ensures rapid heat transfer and moisture removal, reducing overall energy consumption.

Q4: How does the quality of drum-dried products compare to freeze-dried products?

A4: While freeze-dried products generally have superior texture and rehydration properties, drum-dried products offer good quality at a lower cost. Drum drying is particularly effective for products where a slight change in texture or color is acceptable, such as instant soups or powdered ingredients.

Q5: What are the main advantages of using a food drum drying machine in food processing?

A5: The main advantages include energy efficiency, the ability to handle viscous products, continuous operation capabilities, hygienic processing conditions, and the production of shelf-stable powdered products with good nutritional retention.