Content Menu

● Introduction to Room Type Drying Machines

>> 1. Adjustable Temperature Settings

>> 2. Even Air Circulation

>> 3. Multiple Drying Trays

>> 4. Timer Functionality

>> 5. Energy Efficiency

>> 6. Customizable Solutions

>> 7. Moisture Removal System

>> 8. User-Friendly Control Panel

● Benefits of Room Type Drying Machines

● Applications of Room Type Drying Machines

● Maintenance Tips for Room Type Drying Machines

● Conclusion

● Frequently Asked Questions

>> 1. What are the key components of a room type drying machine?

>> 2. How do I choose the right temperature for drying different foods?

>> 3. What is the importance of air circulation in drying?

>> 4. Can room type drying machines be customized?

>> 5. How do I ensure energy efficiency in my drying operations?

● Citations:

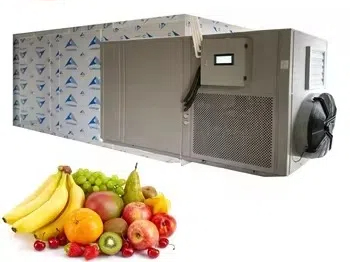

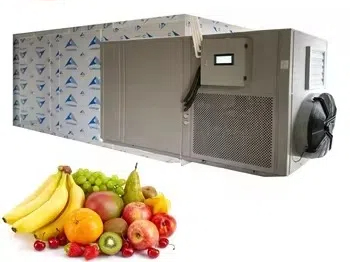

Room type drying machines, also known as enclosed drying systems or batch dryers, are sophisticated pieces of equipment designed to efficiently dry a wide range of materials under controlled conditions. These machines are crucial in the food industry for drying fruits, vegetables, meats, and other products. When selecting a room type drying machine for your food drying needs, there are several key features to consider to ensure optimal performance and efficiency.

Introduction to Room Type Drying Machines

Room type drying machines are versatile and can be used for various applications, from agricultural produce to industrial components. They offer a controlled environment that ensures consistent and high-quality drying results. Here are some of the top features to look for in these machines:

1. Adjustable Temperature Settings

Adjustable temperature settings are crucial for different types of food. Different foods require different drying temperatures to preserve their flavor, texture, and nutritional content effectively. For example, fruits like strawberries and bananas typically require lower temperatures (around 40°C to 50°C) to maintain their flavor and texture, while meats may require higher temperatures (up to 70°C) for safe drying.

This feature allows operators to tailor the drying process according to the specific requirements of each product, ensuring optimal results.

2. Even Air Circulation

Proper air circulation ensures uniform drying throughout the drying chamber, preventing hot spots and ensuring consistent results. Strategically placed vents or fans promote airflow across all trays or shelves.

This is particularly important when dealing with thicker products or larger batches, as uneven air distribution can lead to inconsistent moisture levels and potential spoilage.

3. Multiple Drying Trays

The capacity of the drying machine is important, especially if you plan to dry large batches of food at once. Look for a machine that comes with multiple drying trays or shelves, allowing you to maximize the drying space and process larger quantities of food simultaneously.

Having multiple trays also provides flexibility in terms of product variety; you can dry different types of food at the same time without cross-contamination.

4. Timer Functionality

A timer function is useful for setting the drying duration according to the specific requirements of the food you're drying. This feature ensures consistent results and prevents over-drying, which can lead to loss of flavor and nutrients.

Many modern machines come with digital timers that allow for precise control over the drying process, making it easier for operators to manage multiple batches effectively.

5. Energy Efficiency

Energy efficiency is crucial, especially if you plan to use the machine frequently. Look for models that are designed to operate efficiently and consume minimal energy during the drying process. Features such as insulated drying chambers and low-power fans help reduce electricity consumption.

Energy-efficient machines not only lower operational costs but also contribute positively to environmental sustainability by reducing carbon footprints.

6. Customizable Solutions

Room type drying machines can be customized to meet specific industry requirements and production volumes. This includes adjustable tray heights and customizable drying racks to accommodate foods of varying sizes and thicknesses.

Customization options allow businesses to adapt their equipment as their production needs change over time, ensuring longevity and versatility in operations.

7. Moisture Removal System

Efficient moisture removal is crucial for high-quality drying outcomes. These machines are equipped with advanced moisture extraction mechanisms, such as dehumidifiers or exhaust vents, to continuously remove moisture-laden air from the chamber.

This functionality helps maintain optimal humidity levels within the chamber, which is essential for achieving consistent drying results across all products.

8. User-Friendly Control Panel

A user-friendly control panel enables operators to monitor and adjust critical parameters like temperature, humidity, and airflow, ensuring precise control over the entire drying cycle.

Modern control panels often feature digital displays that provide real-time feedback on operating conditions, making it easier for users to make adjustments as needed.

Benefits of Room Type Drying Machines

1. Consistent Quality: Controlled drying conditions ensure consistent and high-quality results, reducing waste and increasing product value.

2. Energy Efficiency: Advanced heating and moisture removal systems minimize energy consumption, reducing operational costs.

3. Versatility: Suitable for a wide range of materials, from delicate textiles to heavy-duty industrial components.

4. Easy Operation and Maintenance: User-friendly control panels and modular designs facilitate easy operation and maintenance.

5. Customizable Solutions: As a supplier, we offer customized solutions to meet specific industry requirements and production volumes.

Applications of Room Type Drying Machines

Room type drying machines are not limited to food drying; they can also be used for drying industrial components, textiles, and other materials. However, in the context of food drying, they are particularly useful for:

- Fruit and Vegetable Drying: Ideal for preserving fruits and vegetables by removing moisture to prevent spoilage.

- Meat Drying: Suitable for drying meats to make jerky or other dried meat products.

- Seafood Drying: Can be used for drying seafood to preserve it for longer periods.

- Herbs and Spices Drying: Perfect for retaining flavor while extending shelf life.

- Grain Drying: Effective in maintaining grain quality by controlling moisture content during storage.

Maintenance Tips for Room Type Drying Machines

To ensure longevity and optimal performance of your room type drying machine, regular maintenance is essential:

1. Clean Regularly: Remove any residual food particles or dust from trays and surfaces after each use.

2. Inspect Seals: Check door seals regularly for wear or damage; replace them if necessary to maintain insulation efficiency.

3. Calibrate Sensors: Periodically calibrate temperature and humidity sensors to ensure accurate readings.

4. Check Electrical Components: Regularly inspect electrical connections and components for signs of wear or damage.

5. Follow Manufacturer Guidelines: Always adhere to manufacturer maintenance recommendations for best practices.

Conclusion

Room type drying machines are essential for efficient and high-quality drying in various industries, especially in food processing. By considering features such as adjustable temperature settings, even air circulation, multiple drying trays, timer functionality, energy efficiency, customizable solutions, moisture removal systems, and user-friendly control panels, you can ensure that your drying operations are optimized for productivity and quality.

Whether you are a food brand, wholesaler, or manufacturer looking for OEM services, these machines offer a reliable solution for your drying needs while maintaining product integrity through controlled processes.

Frequently Asked Questions

1. What are the key components of a room type drying machine?

The key components include a heating system, air circulation system, insulated chamber, moisture removal system, and a control panel. These components work together to achieve optimal drying performance.

2. How do I choose the right temperature for drying different foods?

Different foods require different drying temperatures. For example, fruits typically require lower temperatures (around 40°C to 50°C), while meats may require higher temperatures (up to 70°C). Always refer to the specific drying guidelines for the type of food you are drying.

3. What is the importance of air circulation in drying?

Proper air circulation ensures uniform drying throughout the chamber, preventing hot spots and ensuring consistent results. It helps in evenly distributing heat and removing moisture efficiently.

4. Can room type drying machines be customized?

Yes, these machines can be customized to meet specific industry requirements and production volumes. This includes adjustable tray heights and customizable drying racks to accommodate foods of varying sizes and thicknesses.

5. How do I ensure energy efficiency in my drying operations?

To ensure energy efficiency, look for machines with features such as insulated drying chambers, low-power fans, and advanced moisture removal systems. These features help reduce electricity consumption and lower operational costs.

Citations:

[1] https://www.dryeratech.com/room-type-drying-machine.html

[2] https://www.dryeratech.com/what-are-some-common-features-to-look-for-in-a-food-drying-machine.html

[3] https://www.bxdrymachine.com/fruit-drying-machine.html

[4] https://www.alamy.com/stock-photo/food-dehydrator.html

[5] https://www.youtube.com/watch?v=JRArvU4PDVc

[6] https://www.youtube.com/watch?v=mtDzdYoyeR8

[7] https://www.dryeratech.com/top-features-to-look-for-in-a-hang-type-drying-machine.html

[8] https://dehydratorchef.com/top-10-features-to-look-for-in-a-food-dehydrator/

[9] https://www.youtube.com/watch?v=qtC36z0HleQ

[10] https://www.istockphoto.com/photos/food-dryer

[11] https://www.helperfoodmachine.com/food-drying-room/

[12] https://www.foodandwine.com/lifestyle/kitchen/best-food-dehydrators

[13] https://www.istockphoto.com/photos/food-dehydrator

[14] https://stock.adobe.com/search?k=dehydrator

[15] https://www.shutterstock.com/search/fruit-dryer

[16] https://hgic.clemson.edu/factsheet/drying-foods/

[17] https://www.dryer.com/harvest-saver-tray-dryer

[18] https://aradmachineryco.com/product/Fruit-dryer-machine

[19] https://www.youtube.com/watch?v=Fhv8Lf5L8Iw

[20] https://www.youtube.com/watch?v=8XID-nxU5K0

[21] https://www.youtube.com/watch?v=rR2G5UO-5Ms