Content Menu

● Understanding Food Drying Machines

>> Types of Food Drying Machines

● How Vented Dryers Work

>> Advantages of Vented Dryers

>> Disadvantages of Vented Dryers

● How Heat Pump Dryers Work

>> Advantages of Heat Pump Dryers

>> Disadvantages of Heat Pump Dryers

● Comparing Vented Dryers and Heat Pump Dryers

● Applications in Food Industry

>> Vented Dryer Applications

>> Heat Pump Dryer Applications

● Choosing the Right Dryer for Your Needs

● Innovations in Food Drying Technology

● Conclusion

● FAQs

>> 1. What is the main difference between a vented dryer and a heat pump dryer?

>> 2. Which dryer is better for preserving nutrients in food?

>> 3. Are vented dryers more cost-effective than heat pump dryers?

>> 4. Can I use a heat pump dryer for all types of foods?

>> 5. How do I determine which dryer is right for my business?

In the world of food processing, drying is a critical step that affects the quality, shelf life, and safety of food products. As a manufacturer of food drying machines, understanding the different types of drying technologies available is essential. This article will explore two popular types of dryers: vented dryers and heat pump dryers, comparing their efficiency, speed, and suitability for various applications in the food industry.

Understanding Food Drying Machines

Food drying machines are designed to remove moisture from food products to prevent spoilage and extend shelf life. The choice of drying technology can significantly impact the quality of the final product.

Types of Food Drying Machines

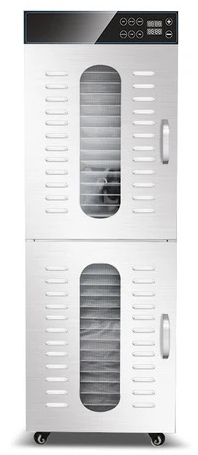

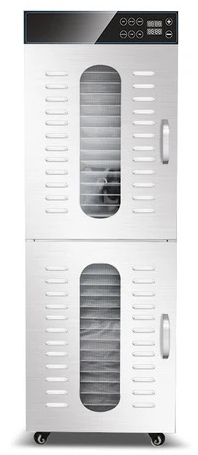

1. Vented Dryers: These dryers work by blowing hot air into the drying chamber, which evaporates moisture from the food. The moist air is then vented outside.

2. Heat Pump Dryers: These utilize a heat pump to recycle air within the chamber, extracting moisture while using less energy compared to vented dryers.

How Vented Dryers Work

Vented dryers operate by introducing heated air into the drying chamber. The process can be broken down into several steps:

- Heating: Air is heated using electric or gas-powered elements.

- Circulation: The hot air circulates around the food items.

- Moisture Removal: As moisture evaporates from the food, it mixes with the circulating air.

- Exhaust: The moist air is expelled outside through vents.

Advantages of Vented Dryers

- Speed: Vented dryers typically dry food faster due to their high airflow and temperature.

- Simplicity: These machines are generally easier to operate and maintain.

- Cost-Effectiveness: Lower initial investment compared to heat pump dryers makes them an attractive option for small-scale operations.

Disadvantages of Vented Dryers

- Energy Consumption: They can be less energy-efficient as they continuously draw in new air and expel moist air.

- Environmental Impact: Releasing hot, moist air can contribute to humidity levels outside.

- Quality Concerns: High temperatures may degrade sensitive nutrients in certain foods.

How Heat Pump Dryers Work

Heat pump dryers use a closed-loop system that recycles air within the drying chamber. This technology operates as follows:

- Air Circulation: Air is circulated through a heat exchanger where it is heated.

- Moisture Extraction: The warm air passes over the food, absorbing moisture.

- Condensation: Moisture-laden air is cooled in another heat exchanger, causing water vapor to condense and collect.

- Recycling Air: The dehumidified air is reheated and cycled back into the chamber.

Advantages of Heat Pump Dryers

- Energy Efficiency: They consume less energy compared to vented dryers due to their recycling process.

- Quality Preservation: Heat pump dryers operate at lower temperatures, which helps preserve sensitive nutrients and flavors in food.

- Versatility: Suitable for a wide range of products including fruits, vegetables, meats, and herbs without compromising quality.

Disadvantages of Heat Pump Dryers

- Drying Speed: They may take longer to dry food compared to vented dryers due to lower airflow and temperature.

- Initial Cost: Heat pump dryers can have a higher upfront cost than vented models.

Comparing Vented Dryers and Heat Pump Dryers

To better understand which dryer may be more suitable for specific applications, we can compare their features side by side:

| Feature | Vented Dryer | Heat Pump Dryer |

| Drying Speed | Faster | Slower |

| Energy Efficiency | Lower | Higher |

| Initial Cost | Lower | Higher |

| Operating Temperature | Higher | Lower |

| Moisture Control | Less effective | More effective |

| Nutrient Preservation | Less effective | More effective |

Applications in Food Industry

Both types of dryers have their place in the food industry. Here are some common applications:

Vented Dryer Applications

- Vegetable Chips: Quick drying helps maintain crispness while ensuring that excess moisture does not lead to spoilage.

- Meat Jerky: Fast drying reduces microbial growth, making it ideal for producing jerky with a longer shelf life.

- Dried Fruits: While not as common, vented dryers can be used for fruits that require quick moisture removal without significant nutrient loss.

Heat Pump Dryer Applications

- Fruits and Vegetables: Gentle drying preserves flavor and nutrients; ideal for delicate items like berries and leafy greens.

- Herbs and Spices: Low-temperature drying maintains essential oils and flavors crucial for culinary applications.

- Fish Products: Suitable for drying fish without compromising texture or taste due to controlled temperature settings.

Choosing the Right Dryer for Your Needs

When deciding between a vented dryer and a heat pump dryer for your food processing needs, consider the following factors:

1. Type of Food Product: Delicate items may benefit from heat pump technology while sturdier products may do well with vented systems.

2. Production Volume: High-volume operations may require faster drying solutions provided by vented dryers.

3. Energy Costs: Evaluate long-term energy costs versus initial investment; heat pump dryers save energy over time despite higher upfront costs.

4. Space Availability: Consider installation space for venting systems or heat pump units; some facilities may have restrictions on where exhaust can be directed.

5. Regulatory Compliance: Ensure that your chosen method meets local food safety regulations; both types should comply but may have different requirements based on operation methods.

6. Maintenance Requirements: Assess how often each type requires maintenance; vented dryers may need more frequent cleaning due to dust accumulation from external air intake.

7. Environmental Considerations: Consider sustainability practices; heat pump dryers are generally more environmentally friendly due to lower energy consumption.

Innovations in Food Drying Technology

With advancements in technology, both vented and heat pump dryers are evolving. Recent innovations include:

- Smart Controls: Many modern dryers come equipped with IoT capabilities that allow users to monitor and control drying processes remotely via smartphone apps. This feature enables precise control over temperature and humidity levels, leading to better product quality.

- Energy Recovery Systems: Some new models incorporate energy recovery systems that capture waste heat from exhaust air in vented systems or utilize it more effectively in heat pump systems, further enhancing energy efficiency.

- Hybrid Systems: Combining elements from both dryer types allows manufacturers to optimize performance based on specific drying needs while minimizing energy consumption and maximizing product quality.

Conclusion

In conclusion, both vented dryers and heat pump dryers offer unique advantages and disadvantages for food processing applications. While vented dryers excel in speed and simplicity, heat pump dryers provide superior energy efficiency and quality preservation. The choice ultimately depends on your specific needs, including the type of food being dried, production volume, energy considerations, budget constraints, and environmental impact assessments.

Investing in the right technology not only enhances product quality but also contributes positively towards sustainability goals in the food industry. As manufacturers continue to innovate within this space, understanding these technologies will remain crucial for businesses aiming to produce high-quality dried foods efficiently.

FAQs

1. What is the main difference between a vented dryer and a heat pump dryer?

The main difference lies in their operation; vented dryers expel moist air outside while heat pump dryers recycle air within a closed system, making them more energy-efficient but slower in drying speed.

2. Which dryer is better for preserving nutrients in food?

Heat pump dryers are better for preserving nutrients because they operate at lower temperatures compared to vented dryers.

3. Are vented dryers more cost-effective than heat pump dryers?

Vented dryers typically have lower initial costs but may lead to higher energy bills over time compared to heat pump dryers, which are more energy-efficient but have higher upfront costs.

4. Can I use a heat pump dryer for all types of foods?

Yes, heat pump dryers can be used for various foods; however, they are particularly beneficial for delicate items like fruits, vegetables, herbs, and spices that require gentle drying methods.

5. How do I determine which dryer is right for my business?

Consider factors such as the type of food products you process, production volume requirements, energy costs, available space for installation, and compliance with local regulations when choosing between a vented or heat pump dryer.