Content Menu

● Understanding Food Drying Technologies

>> Heat Pump Dryers

>> Vented Dryers

● Comparing Heat Pump Dryers and Vented Dryers

● Advantages of Heat Pump Dryers

● Disadvantages of Heat Pump Dryers

● Advantages of Vented Dryers

● Disadvantages of Vented Dryers

● Choosing the Right Dryer for Your Needs

● Real-World Applications

● Conclusion

● FAQ

>> 1. What is the main difference between a heat pump dryer and a vented dryer?

>> 2. Which type of dryer is more energy-efficient?

>> 3. Can I use a heat pump dryer for all types of food?

>> 4. Are vented dryers cheaper than heat pump dryers?

>> 5. How does temperature affect the quality of dried foods?

In the world of food drying, the choice between a heat pump dryer and a vented dryer can significantly impact efficiency, energy consumption, and the quality of the final product. As a manufacturer of food drying machines in China, we understand the importance of selecting the right drying technology for various applications. This article will explore the key differences between heat pump dryers and vented dryers, focusing on their functionality, energy efficiency, and suitability for different types of food products.

Understanding Food Drying Technologies

Food drying is a critical process in food preservation, enhancing shelf life while maintaining flavor and nutritional value. The two primary types of dryers used in this process are heat pump dryers and vented dryers.

Heat Pump Dryers

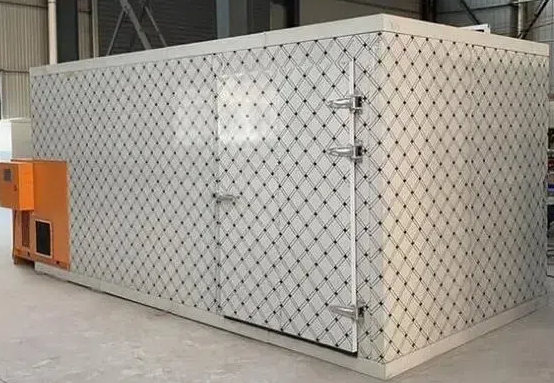

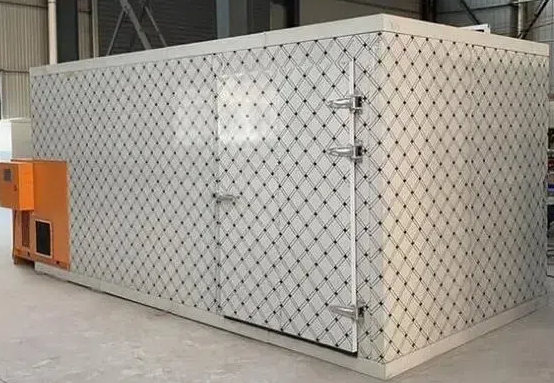

Heat pump dryers utilize a refrigeration cycle to extract moisture from food products. They operate by circulating air through a heat exchanger where moisture is removed. This technology is known for its energy efficiency and ability to maintain low temperatures during the drying process.

Key Features of Heat Pump Dryers:

- Energy Efficiency: Heat pump dryers are designed to recycle heat, making them more energy-efficient than traditional dryers.

- Temperature Control: They allow for precise temperature control, which is crucial for delicate foods that may be damaged by high heat.

- Environmentally Friendly: These dryers use less energy and produce fewer greenhouse gas emissions compared to conventional methods.

- Closed System: Heat pump dryers operate in a closed-loop system, which minimizes moisture loss to the environment and allows for more uniform drying.

Vented Dryers

Vented dryers, on the other hand, operate by drawing in ambient air, heating it, and then expelling the moist air outside. This method is straightforward but can lead to higher energy consumption.

Key Features of Vented Dryers:

- Simplicity: Vented dryers have a simpler design and are generally easier to maintain.

- Higher Operating Temperatures: They can reach higher temperatures quickly, which may be beneficial for certain types of food products.

- Less Initial Investment: Typically, vented dryers are less expensive upfront compared to heat pump dryers.

- Direct Airflow: Vented dryers use direct airflow to remove moisture rapidly but may not provide as even drying as heat pump systems.

Comparing Heat Pump Dryers and Vented Dryers

To better understand the differences between these two types of dryers, let's compare them across several key parameters:

| Feature | Heat Pump Dryer | Vented Dryer |

| Energy Efficiency | High | Moderate to Low |

| Temperature Control | Precise | Less control over temperature |

| Moisture Removal | Efficient moisture extraction | Direct expulsion of moist air |

| Environmental Impact | Lower emissions | Higher emissions |

| Initial Cost | Higher upfront cost | Lower upfront cost |

| Maintenance | More complex maintenance | Easier maintenance |

| Drying Speed | Slower but consistent | Faster but less uniform |

Advantages of Heat Pump Dryers

1. Energy Savings: Heat pump dryers can save up to 50% more energy compared to vented dryers. This is particularly beneficial for businesses looking to reduce operational costs.

2. Better Quality Products: By maintaining lower drying temperatures, heat pump dryers help preserve the nutritional quality and flavor of food products.

3. Versatility: Heat pump technology can be used for various applications beyond food drying, including textiles and pharmaceuticals.

4. Reduced Carbon Footprint: With their lower energy consumption, heat pump dryers contribute to a more sustainable operation.

5. Consistent Results: The closed-loop system ensures that air circulation is uniform, leading to consistent drying results across all batches.

6. Lower Noise Levels: Many heat pump dryers operate more quietly than traditional vented models due to their advanced technology.

Disadvantages of Heat Pump Dryers

1. Higher Initial Investment: The cost of purchasing a heat pump dryer is typically higher than that of a vented dryer.

2. Longer Drying Times: While they are efficient, heat pump dryers may take longer to dry products compared to vented systems due to lower operating temperatures.

3. Complexity in Maintenance: The advanced technology requires more specialized maintenance skills.

4. Potentially Higher Repair Costs: If repairs are needed, they may be more expensive due to the complexity of the system.

Advantages of Vented Dryers

1. Lower Purchase Cost: Vented dryers are generally more affordable upfront, making them accessible for small businesses or startups.

2. Quick Drying Times: These machines can dry products faster due to their ability to reach higher temperatures quickly.

3. Simplicity: The design is straightforward, making them easier to operate and maintain.

4. Fewer Parts: With fewer components than heat pump systems, there is less that can go wrong mechanically.

5. Immediate Moisture Removal: The direct expulsion method allows for quick removal of moisture from the drying chamber.

Disadvantages of Vented Dryers

1. Higher Energy Consumption: Vented dryers typically consume more energy over time due to their reliance on heating ambient air and expelling moisture outside.

2. Quality Concerns: The high temperatures can degrade sensitive food products, affecting taste and nutritional value.

3. Environmental Impact: Increased emissions from higher energy usage contribute negatively to environmental sustainability efforts.

4. Less Control Over Humidity Levels: Since moist air is expelled outside rather than recycled within the system, maintaining optimal humidity levels can be challenging.

5. Heat Loss: The expulsion of hot air means that some energy is wasted as it escapes into the environment rather than being reused within the dryer.

Choosing the Right Dryer for Your Needs

When deciding between a heat pump dryer and a vented dryer for food drying applications, consider the following factors:

- Type of Food Products: Delicate items like fruits or herbs benefit from lower temperatures offered by heat pump dryers.

- Volume of Production: For high-volume operations where speed is essential, vented dryers may be preferable despite their higher energy costs.

- Budget Constraints: Evaluate both initial investment costs and long-term operational expenses when making your decision.

- Sustainability Goals: If reducing your carbon footprint is a priority, heat pump technology may align better with your business objectives.

- Space Considerations: Heat pump dryers often require less space due to their compact design compared to vented systems that need proper ventilation setups.

Real-World Applications

Heat pump and vented dryers find applications across various industries:

- Agriculture: Farmers use these technologies to dry fruits, vegetables, herbs, and grains effectively while preserving their quality.

- Food Processing: Manufacturers benefit from consistent drying processes that improve product shelf life without compromising taste or nutrition.

- Herbal Medicine: In herbal medicine production, maintaining specific temperature ranges is crucial; hence heat pump dryers are often preferred.

- Snack Foods: Companies producing dried snacks like banana chips or apple slices utilize both technologies based on production scale and product sensitivity.

- Pet Food Production: Maintaining high-quality ingredients in pet food requires careful moisture control that heat pump systems provide effectively.

Conclusion

In conclusion, both heat pump dryers and vented dryers have distinct advantages and disadvantages that cater to different needs in food drying processes. Heat pump dryers offer superior energy efficiency and product quality but come with higher initial costs and longer drying times. Conversely, vented dryers provide quicker results at a lower purchase price but at the expense of greater energy consumption and potential quality loss.

Ultimately, the choice between these two technologies should be guided by your specific requirements regarding production volume, product type, budget constraints, and sustainability goals. As a manufacturer dedicated to providing OEM services for food drying machines, we encourage businesses to assess their unique needs carefully before making an investment in drying technology.

FAQ

1. What is the main difference between a heat pump dryer and a vented dryer?

The main difference lies in their operation; heat pump dryers recycle heat for efficient moisture removal at lower temperatures while vented dryers expel moist air outside after heating ambient air.

2. Which type of dryer is more energy-efficient?

Heat pump dryers are significantly more energy-efficient than vented dryers due to their ability to recycle heat during the drying process.

3. Can I use a heat pump dryer for all types of food?

Yes, heat pump dryers are versatile and suitable for various types of food products, especially delicate items that require careful temperature control.

4. Are vented dryers cheaper than heat pump dryers?

Yes, vented dryers generally have a lower initial purchase cost compared to heat pump dryers but may incur higher operational costs over time due to increased energy consumption.

5. How does temperature affect the quality of dried foods?

Higher temperatures can degrade sensitive foods' flavor and nutritional value; therefore, using a dryer that maintains lower temperatures can help preserve these qualities better.