Content Menu

● Understanding Food Drying

● Heat Pump Dryers

>> Advantages of Heat Pump Dryers

● Condenser Dryers

>> Advantages of Condenser Dryers

● Key Differences Between Heat Pump and Condenser Dryers

● Applications in Food Processing

>> Specific Use Cases

● Technological Advancements

● Conclusion

● Frequently Asked Questions

>> 1. What is the main advantage of using a heat pump dryer?

>> 2. Can condenser dryers be used for all types of food?

>> 3. How do heat pump dryers affect the nutritional value of food?

>> 4. What types of food are best dried using heat pump technology?

>> 5. Are heat pump dryers more expensive than condenser dryers?

In the world of food processing, drying is a crucial step that affects the quality, shelf life, and flavor of food products. As a leading manufacturer of food drying machines in China, we specialize in providing OEM services to international brands, wholesalers, and manufacturers. While our focus is on food drying equipment, understanding the differences between heat pump and condenser dryers can provide valuable insights into the technology that underpins our machines. This article will explore these differences, their applications in food drying, and how they can impact the efficiency and quality of the drying process.

Understanding Food Drying

Food drying is a method of preserving food by removing moisture, which inhibits the growth of bacteria, yeasts, and molds. The drying process can enhance flavors, reduce weight for easier transport, and extend shelf life. There are various methods of drying food, including air drying, sun drying, and using specialized drying machines. Among these, heat pump and condenser dryers are two popular technologies used in the industry.

Heat Pump Dryers

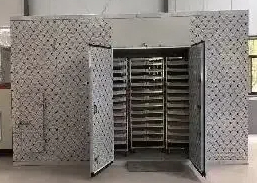

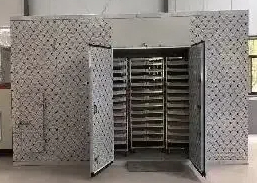

Heat pump dryers utilize a refrigeration cycle to extract moisture from food products. They work by circulating air through a heat exchanger, where the air is heated and then passed over the food. The moisture evaporates and is then condensed back into water, which is collected and removed from the system. This method is highly energy-efficient, as it recycles heat within the system.

Advantages of Heat Pump Dryers

1. Energy Efficiency: Heat pump dryers consume less energy compared to traditional drying methods. They can operate at lower temperatures, which is beneficial for preserving the nutritional quality of food.

2. Consistent Drying: These dryers provide uniform drying conditions, reducing the risk of over-drying or under-drying food products.

3. Versatility: Heat pump dryers can be used for a wide range of food products, including fruits, vegetables, meats, and herbs.

4. Environmentally Friendly: By using less energy and producing less waste heat, heat pump dryers are a more sustainable option for food processing.

Condenser Dryers

Condenser dryers, on the other hand, operate by using a heating element to warm the air, which is then circulated through the drying chamber. The warm air absorbs moisture from the food, and the humid air is then passed through a condenser, where the moisture is removed and collected. This method is commonly used in both domestic and industrial applications.

Advantages of Condenser Dryers

1. Simplicity: Condenser dryers are generally easier to operate and maintain compared to heat pump dryers.

2. Lower Initial Cost: These dryers often have a lower purchase price, making them an attractive option for small-scale operations.

3. Faster Drying Times: Condenser dryers can achieve higher temperatures, which may result in quicker drying times for certain products.

Key Differences Between Heat Pump and Condenser Dryers

1. Energy Consumption: Heat pump dryers are more energy-efficient, using less electricity to achieve the same drying results as condenser dryers.

2. Temperature Control: Heat pump dryers operate at lower temperatures, which helps preserve the quality of sensitive food products. In contrast, condenser dryers can reach higher temperatures, which may not be suitable for all types of food.

3. Moisture Removal: Heat pump dryers recycle moisture within the system, while condenser dryers expel humid air outside. This can affect the drying environment and the overall efficiency of the process.

4. Cost: While heat pump dryers may have a higher initial investment, their energy savings can lead to lower operational costs over time. Condenser dryers are typically less expensive upfront but may incur higher energy costs.

5. Application Suitability: Heat pump dryers are ideal for a wide range of food products, especially those that require gentle drying. Condenser dryers may be better suited for products that can withstand higher temperatures.

Applications in Food Processing

In the food industry, the choice between heat pump and condenser dryers often depends on the specific requirements of the product being dried. For example, heat pump dryers are commonly used for drying fruits and vegetables, where maintaining flavor and nutritional value is essential. They are also suitable for drying herbs and spices, which can lose their potency if exposed to high temperatures.

Condenser dryers, on the other hand, may be used for drying more robust products, such as meats and fish, where faster drying times are advantageous. They can also be effective for drying grains and legumes, which can tolerate higher temperatures without compromising quality.

Specific Use Cases

1. Fruits and Vegetables: Heat pump dryers are particularly effective for drying fruits like apples, bananas, and berries. The low-temperature drying process helps retain the vibrant colors and flavors of the fruits, making them more appealing to consumers. For vegetables, such as carrots and peas, heat pump dryers ensure that the nutritional content is preserved while achieving the desired texture.

2. Herbs and Spices: The delicate nature of herbs and spices makes them ideal candidates for heat pump drying. The gentle drying process prevents the loss of essential oils and flavors, resulting in high-quality dried herbs that retain their aromatic properties.

3. Meats and Fish: Condenser dryers are often preferred for drying meats and fish due to their ability to achieve higher temperatures. This is particularly important for products like jerky, where rapid moisture removal is necessary to prevent spoilage. The faster drying times can also enhance the texture and flavor of the final product.

4. Grains and Legumes: For grains and legumes, condenser dryers can effectively reduce moisture content quickly, which is essential for preventing mold growth during storage. The ability to control drying temperatures allows processors to achieve optimal results without compromising quality.

Technological Advancements

As technology continues to evolve, both heat pump and condenser dryers are becoming more sophisticated. Innovations in control systems, energy efficiency, and automation are enhancing the performance of these machines. For instance, modern heat pump dryers may incorporate advanced sensors that monitor moisture levels in real-time, allowing for precise control over the drying process. This not only improves efficiency but also ensures consistent product quality.

Similarly, condenser dryers are benefiting from improved heat exchange technologies that enhance energy efficiency. Manufacturers are increasingly focusing on developing dryers that minimize energy consumption while maximizing drying performance.

Conclusion

Understanding the differences between heat pump and condenser dryers is essential for food manufacturers looking to optimize their drying processes. Each technology has its advantages and is suited for different applications. As a leading manufacturer of food drying machines, we are committed to providing our clients with the best solutions tailored to their specific needs.

By choosing the right drying technology, food processors can enhance product quality, improve energy efficiency, and ultimately increase profitability. Whether you are a brand, wholesaler, or manufacturer, our OEM services can help you find the perfect drying solution for your business.

Frequently Asked Questions

1. What is the main advantage of using a heat pump dryer?

The main advantage of a heat pump dryer is its energy efficiency, as it uses less electricity and operates at lower temperatures, preserving the quality of food.

2. Can condenser dryers be used for all types of food?

While condenser dryers can be used for many food types, they are best suited for products that can withstand higher temperatures.

3. How do heat pump dryers affect the nutritional value of food?

Heat pump dryers help preserve the nutritional value of food by operating at lower temperatures, reducing the risk of nutrient loss.

4. What types of food are best dried using heat pump technology?

Heat pump technology is ideal for drying fruits, vegetables, herbs, and other sensitive food products.

5. Are heat pump dryers more expensive than condenser dryers?

Yes, heat pump dryers typically have a higher initial cost, but they can lead to lower operational costs due to their energy efficiency.