Content Menu

● Understanding Heat Pump Dryers

● Key Physics Principles

>> 1. Thermodynamics

>> 2. Heat Transfer

>> 3. Psychrometrics

● Advantages of Heat Pump Dryers

● Applications in Food Drying

● Technical Considerations

● Future Trends in Heat Pump Dryers

● Conclusion

● FAQs

>> 1. What is a heat pump dryer?

>> 2. How does a heat pump dryer save energy?

>> 3. Can a heat pump dryer be used for food dehydration?

>> 4. What are common maintenance requirements for heat pump dryers?

>> 5. Are there any drawbacks to using a heat pump dryer?

● Citations:

Heat pump dryers are an innovative solution for drying clothes and food products efficiently. They operate on principles of thermodynamics and fluid mechanics, utilizing a closed-loop system that recycles air to achieve moisture removal. This article will delve into the key physics principles behind heat pump dryers, particularly focusing on their application in food drying processes.

Understanding Heat Pump Dryers

A heat pump dryer functions by using a refrigeration cycle to transfer heat from one area to another, effectively drying materials without the need for venting hot air outside. Unlike traditional dryers that expel warm, moist air, heat pump dryers recycle this air, making them more energy-efficient.

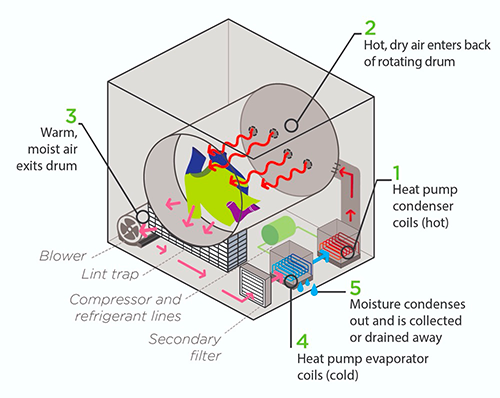

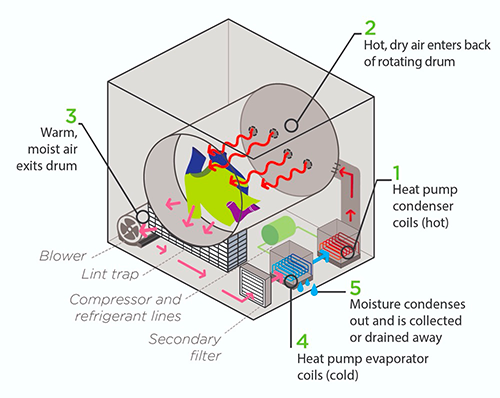

1. Refrigeration Cycle: The core of a heat pump dryer is its refrigeration cycle, which consists of four main components:

- Compressor: Increases the pressure of the refrigerant, raising its temperature.

- Condenser: Releases heat to the air while the refrigerant condenses from gas to liquid.

- Expansion Valve: Reduces the pressure of the refrigerant, allowing it to cool.

- Evaporator: Absorbs heat from the air as the refrigerant evaporates back into gas.

2. Closed Loop System: The air inside the dryer circulates through these components in a closed loop. Warm air enters the drum, absorbs moisture from the clothes or food, and then passes through the evaporator where moisture is condensed and drained away.

Key Physics Principles

The functioning of heat pump dryers is governed by several key physics principles:

1. Thermodynamics

The laws of thermodynamics explain how energy is transferred and transformed within the dryer system.

- First Law of Thermodynamics: Energy cannot be created or destroyed; it can only change forms. In a heat pump dryer, electrical energy powers the compressor, which converts this energy into thermal energy used for drying.

- Second Law of Thermodynamics: Heat naturally flows from hot to cold. The heat pump dryer utilizes this principle by transferring heat from the refrigerant to the air in the drum, thus raising its temperature and capacity to absorb moisture.

2. Heat Transfer

Heat transfer mechanisms—conduction, convection, and radiation—play crucial roles in how effectively a heat pump dryer operates.

- Conduction: Heat is conducted through the walls of the dryer components (like coils) where hot refrigerant transfers its heat to cooler air.

- Convection: The movement of air within the drum and through the evaporator involves convection currents that help distribute heat evenly across all items being dried.

- Evaporation and Condensation: Moisture evaporates from wet items as warm air circulates around them. This moisture-laden air then passes through the evaporator where it cools down, causing water vapor to condense into liquid water.

3. Psychrometrics

Psychrometry is essential for understanding how temperature and humidity affect drying processes.

- Humidity Ratios: The ability of air to hold moisture increases with temperature. By heating the air in the drum, a heat pump dryer significantly enhances its drying capacity.

- Dew Point: This is critical in determining when condensation occurs. By controlling temperatures within specific ranges, heat pump dryers can optimize moisture removal without over-drying materials.

Advantages of Heat Pump Dryers

Heat pump dryers offer numerous benefits compared to conventional drying methods:

- Energy Efficiency: They consume 40-50% less energy than standard electric dryers due to their recycling method and lower operating temperatures.

- Versatility: Suitable for various applications beyond laundry, including food dehydration, which requires careful control of temperature and humidity levels.

- Environmental Impact: By reducing energy consumption and eliminating venting requirements, these dryers have a lower environmental footprint.

Applications in Food Drying

In food processing, maintaining quality while removing moisture is crucial. Heat pump dryers are increasingly used for dehydrating fruits, vegetables, and meats due to their precise control over drying conditions.

1. Quality Preservation: Gentle drying at lower temperatures helps preserve flavor, color, and nutritional value better than traditional methods that may use higher temperatures. For example, drying fruits like apples or bananas at lower temperatures can retain their natural sweetness and vibrant colors.

2. Uniform Drying: The closed-loop system ensures consistent airflow and temperature distribution throughout the drying chamber, leading to uniform results. This is particularly important for products like herbs or leafy greens where uneven drying can lead to spoilage or loss of flavor.

3. Reduced Risk of Spoilage: By efficiently removing moisture without excessive heat exposure, heat pump dryers minimize risks associated with spoilage and microbial growth. This is especially beneficial for meat products where proper drying can prevent bacterial growth that leads to foodborne illnesses.

4. Extended Shelf Life: Properly dried foods have a significantly longer shelf life compared to those dried using traditional methods. This allows manufacturers to reduce waste and improve profitability while providing consumers with high-quality products.

5. Flexibility in Processing: Heat pump dryers can be adjusted for various drying profiles depending on the type of food being processed. For instance, different fruits may require specific temperature settings and drying times to achieve optimal results without compromising quality.

Technical Considerations

When implementing a heat pump dryer for food processing or other applications, several technical considerations must be taken into account:

1. Sizing and Capacity: Selecting an appropriately sized unit is crucial for efficiency and effectiveness. A unit that is too small may not handle larger batches effectively while one that is too large could lead to unnecessary energy consumption.

2. Control Systems: Advanced control systems allow operators to monitor and adjust parameters such as temperature and humidity in real-time. This capability enhances precision in achieving desired drying outcomes.

3. Maintenance Requirements: Regular maintenance is essential for optimal performance. This includes cleaning filters, checking refrigerant levels, and ensuring that all components are functioning correctly to prevent breakdowns and maintain efficiency.

4. Integration with Existing Systems: For businesses already using other types of dryers or processing equipment, integrating a heat pump dryer may require modifications or additional investments in infrastructure to ensure compatibility.

5. Cost Considerations: While initial investment costs for heat pump dryers may be higher than traditional systems, long-term savings on energy bills and improved product quality often justify this expense over time.

Future Trends in Heat Pump Dryers

As technology continues to evolve, several trends are emerging in the field of heat pump dryers:

1. Smart Technology Integration: The incorporation of IoT (Internet of Things) technology allows for remote monitoring and control of dryer systems via smartphones or computers. This enhances operational efficiency by enabling real-time adjustments based on environmental conditions or production needs.

2. Sustainability Focus: With increasing emphasis on sustainability in manufacturing processes, more companies are adopting heat pump technology as part of their commitment to reducing carbon footprints and conserving energy resources.

3. Research and Development: Ongoing research into advanced materials for insulation and more efficient refrigerants aims to further enhance the performance of heat pump dryers while reducing environmental impact.

4. Market Growth: As awareness grows regarding energy efficiency and product quality benefits associated with heat pump dryers, demand is expected to rise across various sectors beyond just textiles—particularly in food processing industries looking for sustainable solutions.

5. Customization Options: Manufacturers are increasingly offering customizable solutions tailored specifically for different industries or product types—allowing businesses greater flexibility in their operations while maximizing efficiency gains from these systems.

Conclusion

Heat pump dryers represent a significant advancement in drying technology by leveraging key physics principles such as thermodynamics and psychrometrics. Their ability to recycle air not only enhances energy efficiency but also provides superior quality preservation for both textiles and food products. As sustainability becomes increasingly important in manufacturing processes, these systems will likely see wider adoption across various industries due to their versatility and effectiveness in maintaining product integrity during drying processes.

FAQs

1. What is a heat pump dryer?

A heat pump dryer uses a refrigeration cycle to recycle warm air for drying clothes or food without venting hot air outside.

2. How does a heat pump dryer save energy?

It recycles warm air instead of expelling it, requiring less energy than traditional dryers that continuously generate new hot air.

3. Can a heat pump dryer be used for food dehydration?

Yes, they are effective for food dehydration as they allow precise control over temperature and humidity during the drying process.

4. What are common maintenance requirements for heat pump dryers?

Regular cleaning of filters and coils is necessary to maintain efficiency and prevent issues like longer drying times or mold growth.

5. Are there any drawbacks to using a heat pump dryer?

They may have longer drying times compared to conventional dryers and typically have smaller drum capacities.

Citations:

[1] https://docs.lib.purdue.edu/cgi/viewcontent.cgi?params=%2Fcontext%2Firacc%2Farticle%2F2754%2F&path_info=Contribution2440_final.pdf

[2] https://www.familyhandyman.com/article/heat-pump-dryer/

[3] https://www.sciencedirect.com/science/article/pii/S0038092X96001302

[4] https://www.youtube.com/watch?v=DeN-h6opueM

[5] https://www.ike.cn/video.html

[6] https://www.sciencedirect.com/science/article/pii/S2214157X22001587

[7] https://undecidedmf.com/are-heat-pump-dryers-really-worth-it-miele-dryer-review/

[8] https://www.frontiersin.org/journals/sustainable-food-systems/articles/10.3389/fsufs.2020.606845/full

[9] https://www.youtube.com/watch?v=S-hDpODzIV0

[10] https://www.youtube.com/watch?v=rR2G5UO-5Ms