Content Menu

● Introduction to Food Drying

● Types of Dryers

● Pros and Cons of Heat Pump Dryers

>> Pros

>> Cons

● Pros and Cons of Condenser Dryers

>> Pros

>> Cons

● Choosing the Right Dryer for Your Food Processing Needs

● Conclusion

● Frequently Asked Questions

>> 1. What is the main difference between heat pump dryers and condenser dryers?

>> 2. Which dryer is better for drying fruits and vegetables?

>> 3. Are heat pump dryers more expensive to maintain?

>> 4. Can condenser dryers be used for all types of food?

>> 5. How do I determine the best dryer for my business?

In the world of food processing, drying is a crucial step that affects the quality, shelf life, and flavor of the final product. As a manufacturer of food drying machines, understanding the differences between heat pump dryers and condenser dryers is essential for optimizing your production process. This article will explore the pros and cons of each type of dryer, focusing on their applications in food drying, energy efficiency, operational costs, and overall effectiveness.

Introduction to Food Drying

Food drying is a method of preserving food by removing moisture, which inhibits the growth of bacteria, yeasts, and molds. This process can enhance flavors, improve texture, and extend the shelf life of various food products, including fruits, vegetables, meats, and herbs. The choice of drying technology can significantly impact the quality and efficiency of the drying process.

Types of Dryers

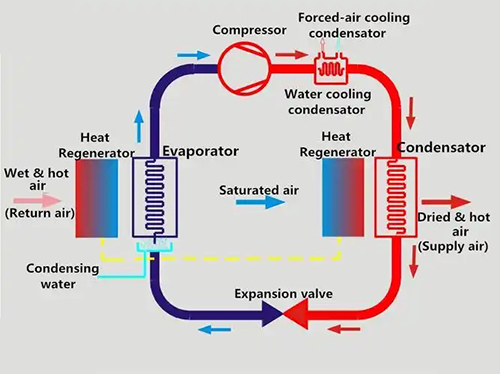

1. Heat Pump Dryers: These dryers use a refrigeration cycle to remove moisture from food products. They operate at lower temperatures, making them suitable for delicate items that require gentle drying.

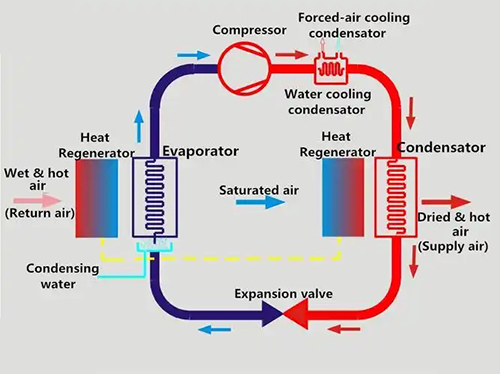

2. Condenser Dryers: These dryers work by heating air and passing it through the food, then cooling the air to condense the moisture, which is collected in a tank. They typically operate at higher temperatures, making them effective for a wide range of food products.

Pros and Cons of Heat Pump Dryers

Pros

1. Energy Efficiency: Heat pump dryers are known for their energy efficiency. They recycle heat within the system, which reduces energy consumption compared to traditional drying methods. This is particularly beneficial for large-scale food processing operations where energy costs can be significant.

2. Gentle Drying: The lower operating temperatures of heat pump dryers make them ideal for drying sensitive foods, such as herbs and fruits. This gentle drying process helps preserve the nutritional value and flavor of the food.

3. Moisture Control: Heat pump dryers allow for precise control over humidity levels, which can be adjusted according to the specific requirements of different food products. This feature helps achieve consistent drying results.

4. Environmentally Friendly: By using less energy and producing fewer emissions, heat pump dryers are a more sustainable option for food processing facilities looking to reduce their carbon footprint.

5. Versatility: These dryers can be used for a wide variety of food products, making them a versatile choice for manufacturers who process different types of foods.

Cons

1. Higher Initial Cost: The upfront investment for heat pump dryers can be higher than that of condenser dryers. This may be a barrier for smaller operations or those with limited budgets.

2. Longer Drying Times: While heat pump dryers are energy-efficient, they may require longer drying times compared to condenser dryers. This can be a disadvantage for businesses that need to process large quantities of food quickly.

3. Maintenance Requirements: Heat pump dryers may require more maintenance due to their complex systems. Regular servicing is essential to ensure optimal performance and longevity.

Pros and Cons of Condenser Dryers

Pros

1. Faster Drying Times: Condenser dryers typically operate at higher temperatures, which can lead to faster drying times. This is advantageous for businesses that need to maximize throughput and efficiency.

2. Lower Initial Cost: Generally, condenser dryers have a lower initial purchase price compared to heat pump dryers, making them more accessible for smaller operations or startups.

3. Simplicity of Operation: The technology behind condenser dryers is often simpler, which can make them easier to operate and maintain. This can be beneficial for facilities with limited technical expertise.

4. Effective for a Wide Range of Products: Condenser dryers can effectively dry a variety of food products, including meats, grains, and vegetables, making them a versatile option for many food processing applications.

Cons

1. Higher Energy Consumption: Condenser dryers tend to consume more energy due to their higher operating temperatures. This can lead to increased operational costs over time, especially in large-scale operations.

2. Potential for Nutrient Loss: The higher temperatures used in condenser dryers can lead to the degradation of certain nutrients and flavors in sensitive food products. This is a critical consideration for manufacturers focused on quality.

3. Less Control Over Humidity: While condenser dryers can effectively remove moisture, they may not offer the same level of humidity control as heat pump dryers. This can result in inconsistent drying results for certain products.

4. Environmental Impact: The higher energy consumption of condenser dryers can contribute to a larger carbon footprint, which may be a concern for environmentally conscious businesses.

Choosing the Right Dryer for Your Food Processing Needs

When deciding between a heat pump dryer and a condenser dryer, it is essential to consider several factors:

1. Type of Food Products: If you are processing delicate items that require gentle drying, a heat pump dryer may be the better choice. For more robust products that can withstand higher temperatures, a condenser dryer may be more suitable.

2. Production Volume: For high-volume operations where speed is critical, condenser dryers may offer the advantage of faster drying times. However, if energy efficiency and product quality are priorities, heat pump dryers may be worth the investment.

3. Budget: Consider your initial investment and long-term operational costs. While heat pump dryers may have a higher upfront cost, their energy savings can offset this over time.

4. Space and Installation: Evaluate the space available for installation. Heat pump dryers may require more space due to their additional components, while condenser dryers may be more compact.

5. Environmental Considerations: If sustainability is a priority for your business, heat pump dryers may align better with your goals due to their lower energy consumption and reduced emissions.

Conclusion

Both heat pump dryers and condenser dryers have their advantages and disadvantages when it comes to food drying. The choice between the two will depend on your specific needs, including the types of food you process, your production volume, and your budget. By carefully considering these factors, you can select the right drying technology to enhance your food processing operations.

Frequently Asked Questions

1. What is the main difference between heat pump dryers and condenser dryers?

Heat pump dryers operate at lower temperatures and recycle heat, making them more energy-efficient, while condenser dryers use higher temperatures for faster drying.

2. Which dryer is better for drying fruits and vegetables?

Heat pump dryers are generally better for drying fruits and vegetables due to their gentle drying process, which helps preserve flavor and nutrients.

3. Are heat pump dryers more expensive to maintain?

Yes, heat pump dryers may require more maintenance due to their complex systems, but they can offer long-term energy savings.

4. Can condenser dryers be used for all types of food?

Yes, condenser dryers can effectively dry a wide range of food products, but they may not be suitable for very delicate items.

5. How do I determine the best dryer for my business?

Consider factors such as the type of food products, production volume, budget, space for installation, and environmental goals when choosing a dryer.