Content Menu

● Introduction

● What is a Food Dehydrator?

>> Types of Food Dehydrators

● How Does a Food Dehydrator Work?

>> Heat Pump vs. Vented Dryers

● Benefits of Using a Food Dehydrator

>> Energy Efficiency

● Choosing Between Condenser Heat Pump and Vented Dryer

>> Energy Consumption

>> Moisture Control

>> Installation Requirements

>> Cost Considerations

● Applications of Food Dehydrators

>> Home Use vs. Industrial Use

● Key Features to Look For

>> Temperature Control

>> Airflow Design

>> Capacity

● Tips for Successful Food Dehydration

>> Preparation

>> Spacing

>> Monitoring Progress

● Conclusion

● Frequently Asked Questions

>> 1. What is the main difference between a condenser heat pump and a vented dryer?

>> 2. Are condenser heat pumps more energy-efficient than vented dryers?

>> 3. Can I use a food dehydrator for all types of food?

>> 4. How long does it take to dehydrate food?

>> 5. What maintenance is required for food dehydrators?

Introduction

Food dehydrators are essential tools in the food processing industry, allowing for the preservation of fruits, vegetables, meats, and other food items by removing moisture. This process not only extends shelf life but also enhances flavors and nutritional content. In this article, we will explore the various aspects of food dehydrators, particularly focusing on the differences between condenser heat pump systems and vented dryers.

What is a Food Dehydrator?

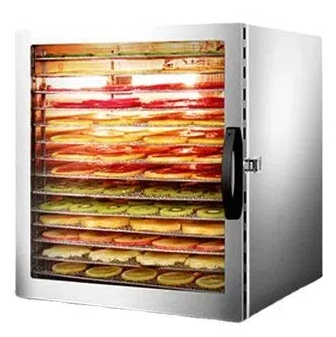

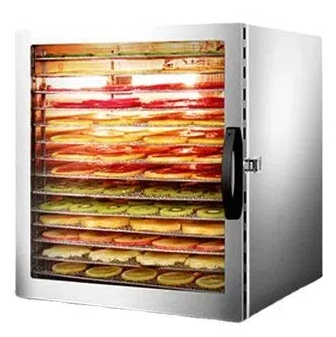

A food dehydrator is a device that removes moisture from food to inhibit the growth of bacteria, yeast, and mold. The dehydration process involves applying low heat and airflow to evaporate moisture content in food items.

Types of Food Dehydrators

1. Condenser Heat Pump Dehydrators: These units use a heat pump to recycle air, making them energy efficient. They condense moisture from the air and collect it in a reservoir.

2. Vented Dryers: These machines expel moist air outside through vents, which can lead to energy loss and require proper installation.

How Does a Food Dehydrator Work?

The operation of a food dehydrator involves several steps:

1. Heating: The dehydrator heats the air inside the chamber.

2. Circulation: A fan circulates the hot air around the food trays.

3. Moisture Removal: As moisture evaporates from the food, it either condenses on the walls of the chamber or is expelled (in vented systems).

Heat Pump vs. Vented Dryers

1. Heat Pump: Utilizes energy-efficient methods to maintain temperature and humidity levels.

2. Vented Dryer: Relies on external air flow, which can lead to inconsistent drying results.

Benefits of Using a Food Dehydrator

Using a food dehydrator offers numerous advantages:

1. Extended Shelf Life: Dehydration significantly prolongs the freshness of foods.

2. Nutrient Preservation: Properly dried foods retain most of their vitamins and minerals.

3. Flavor Enhancement: Concentrating flavors through dehydration can enhance taste.

Energy Efficiency

When comparing energy consumption between condenser heat pump systems and vented dryers, heat pumps are generally more efficient due to their recycling of hot air.

Choosing Between Condenser Heat Pump and Vented Dryer

When selecting a food dehydrator, consider these factors:

Energy Consumption

1. Condenser Heat Pump: Lower energy costs due to efficient operation.

2. Vented Dryer: Higher energy costs as it expels hot air.

Moisture Control

1. Condenser Heat Pump: Better at controlling humidity levels within the drying chamber.

2. Vented Dryer: May struggle with maintaining consistent humidity.

Installation Requirements

1. Condenser Heat Pump: Typically requires less installation space as it does not need external venting.

2. Vented Dryer: Requires proper ventilation setup which can limit placement options.

Cost Considerations

While initial costs may be higher for condenser heat pumps, their long-term savings on energy bills can make them more economical over time. Vented dryers may have lower upfront costs but could result in higher operational expenses due to energy inefficiency.

Applications of Food Dehydrators

Food dehydrators are versatile machines used in various industries:

1. Agriculture: Drying fruits and vegetables for storage or sale.

2. Food Processing: Preparing snacks like jerky or dried fruits.

3. Pharmaceuticals: Drying herbs and medicinal plants for extraction processes.

Home Use vs. Industrial Use

While many people use smaller dehydrators at home for personal use, larger industrial models are designed for high-volume production. These industrial units often feature advanced technology such as programmable settings, larger capacities, and improved energy efficiency.

Key Features to Look For

When purchasing a food dehydrator, consider these important features:

Temperature Control

Having adjustable temperature settings allows you to dehydrate various types of foods effectively. Different foods require different temperatures for optimal drying.

Airflow Design

The design of airflow is crucial for even drying. Look for models that provide uniform airflow across all trays to prevent uneven drying.

Capacity

Consider how much food you plan to dehydrate at once. Larger models can accommodate more trays and larger batches, making them suitable for commercial use.

Tips for Successful Food Dehydration

To achieve the best results when using a food dehydrator, follow these tips:

Preparation

Properly prepare your food by washing, slicing, and blanching (if necessary) before placing it in the dehydrator.

Spacing

Ensure there is enough space between pieces of food on each tray to allow for proper airflow.

Monitoring Progress

Check on your food periodically during the dehydration process to ensure it is drying evenly and adjust settings as needed.

Conclusion

Choosing between a condenser heat pump and a vented dryer for food dehydration depends on your specific needs regarding energy efficiency, moisture control, installation requirements, and cost considerations. Understanding these differences can help you make an informed decision that aligns with your production goals.

Frequently Asked Questions

1. What is the main difference between a condenser heat pump and a vented dryer?

The main difference lies in how they handle moisture; condenser heat pumps recycle air and condense moisture, while vented dryers expel moist air outside.

2. Are condenser heat pumps more energy-efficient than vented dryers?

Yes, condenser heat pumps are generally more energy-efficient because they reuse hot air instead of expelling it.

3. Can I use a food dehydrator for all types of food?

Most food dehydrators can handle fruits, vegetables, meats, and herbs; however, always check manufacturer guidelines for specific foods.

4. How long does it take to dehydrate food?

Dehydration times vary based on food type and thickness but typically range from several hours to over a day.

5. What maintenance is required for food dehydrators?

Regular cleaning of trays and checking for any blockages in airflow are essential for optimal performance.