Content Menu

● Introduction

● What is a Heat Pump Compact Dryer?

● Benefits of Using Heat Pump Dryers for Food

● Types of Food Drying Machines

● Applications of Heat Pump Dryers in Food Industry

● How to Choose the Right Food Drying Machine

● Maintenance and Care for Food Drying Machines

● Future Trends in Food Drying Technology

● Conclusion

● Frequently Asked Questions

>> 1. What is the difference between a heat pump dryer and a conventional dryer?

>> 2. Can heat pump dryers be used for all types of food?

>> 3. How long does it take to dry food using a heat pump dryer?

>> 4. Are heat pump dryers environmentally friendly?

>> 5. What maintenance is required for food drying machines?

Introduction

Food preservation is a critical aspect of the food industry, ensuring that products remain safe, nutritious, and flavorful over time. Among various preservation methods, drying is one of the oldest and most effective techniques. In recent years, heat pump technology has emerged as a revolutionary method for drying food, offering numerous advantages over traditional drying methods. This article explores the benefits of heat pump dryers, their applications in the food industry, and how they contribute to sustainable food practices.

What is a Heat Pump Compact Dryer?

A heat pump compact dryer is a modern appliance that utilizes a heat pump system to remove moisture from food. Unlike conventional dryers that expel hot air, heat pump dryers recycle air within a closed system. This process involves drawing in ambient air, heating it, and passing it over the food to evaporate moisture. The moisture-laden air is then cooled, causing the water vapor to condense and be collected, while the dry air is reheated and recirculated. This method not only conserves energy but also maintains a consistent drying temperature, which is crucial for preserving the quality of food.

Benefits of Using Heat Pump Dryers for Food

Heat pump dryers offer several benefits that make them an attractive option for food preservation:

1. Energy Efficiency: Heat pump dryers consume significantly less energy than traditional dryers. By recycling air and using lower temperatures, they reduce electricity costs and environmental impact.

2. Nutrient Preservation: The gentle drying process helps retain the nutritional value of food. Unlike high-temperature methods that can degrade vitamins and minerals, heat pump dryers maintain the integrity of the food.

3. Versatility: These dryers can handle a wide variety of food items, including fruits, vegetables, meats, and herbs. This versatility makes them suitable for both home and commercial use.

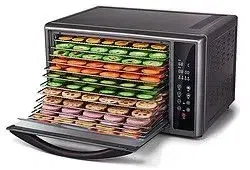

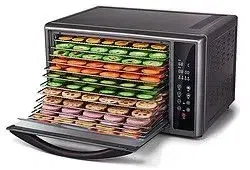

Types of Food Drying Machines

There are several types of food drying machines available, each with its own advantages and disadvantages:

1. Convection Dryers: Use hot air to dry food. They are effective but can lead to uneven drying and nutrient loss.

2. Freeze-Dryers: Remove moisture by freezing food and then evaporating the ice. This method preserves flavor and nutrients but is more expensive and time-consuming.

3. Heat Pump Dryers: Combine the benefits of both convection and freeze-drying, offering energy efficiency and nutrient preservation.

Applications of Heat Pump Dryers in Food Industry

Heat pump dryers are increasingly being adopted in the food industry for various applications:

1. Commercial Food Production: Many food manufacturers use heat pump dryers to produce dried fruits, vegetables, and snacks. The ability to maintain consistent quality and reduce energy costs makes them a preferred choice.

2. Case Studies: Companies that have implemented heat pump technology report significant improvements in product quality and reductions in energy consumption. For instance, a fruit processing plant noted a 30% decrease in energy costs after switching to heat pump dryers.

How to Choose the Right Food Drying Machine

Selecting the appropriate food drying machine involves considering several factors:

1. Capacity: Determine the volume of food you plan to dry. Larger operations may require industrial-sized machines, while smaller operations can benefit from compact models.

2. Energy Consumption: Look for energy-efficient models that can help reduce operational costs.

3. Technology: Evaluate the drying technology that best suits your needs, whether it be heat pump, convection, or freeze-drying.

Maintenance and Care for Food Drying Machines

Proper maintenance is essential for ensuring the longevity and efficiency of food drying machines:

1. Regular Cleaning: Clean trays and surfaces to prevent contamination and ensure optimal airflow.

2. Check for Blockages: Inspect air vents and moisture collection systems regularly to avoid performance issues.

3. Troubleshooting: Familiarize yourself with common problems and solutions to maintain smooth operation.

Future Trends in Food Drying Technology

The future of food drying technology looks promising, with ongoing innovations in heat pump systems. As sustainability becomes a priority in food processing, heat pump dryers are expected to play a significant role in reducing energy consumption and waste. Advances in automation and smart technology will also enhance the efficiency and user-friendliness of these machines.

Conclusion

Heat pump dryers represent a significant advancement in food preservation technology. Their energy efficiency, ability to retain nutrients, and versatility make them an ideal choice for both home and commercial applications. As the food industry continues to evolve, embracing modern drying technologies will be crucial for ensuring high-quality products and sustainable practices.

Frequently Asked Questions

1. What is the difference between a heat pump dryer and a conventional dryer?

Heat pump dryers use a closed-loop system to recycle air and moisture, making them more energy-efficient compared to conventional dryers that vent hot air outside.

2. Can heat pump dryers be used for all types of food?

Yes, heat pump dryers are versatile and can effectively dry fruits, vegetables, meats, and herbs.

3. How long does it take to dry food using a heat pump dryer?

Drying times vary based on the type of food and moisture content, but generally, heat pump dryers take longer than conventional methods due to their lower operating temperatures.

4. Are heat pump dryers environmentally friendly?

Yes, they consume less energy and reduce greenhouse gas emissions compared to traditional drying methods.

5. What maintenance is required for food drying machines?

Regular cleaning of trays, checking for blockages in air vents, and ensuring the moisture collection system is functioning properly are essential for optimal performance.