Content Menu

● Introduction

● What is a Heat Pump Dryer?

● Advantages of Heat Pump Dryers in Food Drying

● Disadvantages of Heat Pump Dryers

● The Food Drying Process

● Applications of Heat Pump Dryers in the Food Industry

● Conclusion

● Frequently Asked Questions

>> 1. What types of food can be dried using heat pump dryers?

>> 2. How does a heat pump dryer compare to traditional drying methods?

>> 3. What is the maintenance like for heat pump dryers?

>> 4. Are heat pump dryers suitable for home use?

>> 5. What is the cost difference between heat pump dryers and conventional dryers?

Introduction

Food preservation is a critical aspect of food safety and sustainability. Among various methods, drying is one of the oldest and most effective techniques used to extend the shelf life of food. In recent years, heat pump dryers have emerged as a revolutionary technology in the food drying industry, offering numerous advantages over traditional drying methods. This article explores the role of heat pump dryers in food drying, highlighting their benefits, drawbacks, and applications.

What is a Heat Pump Dryer?

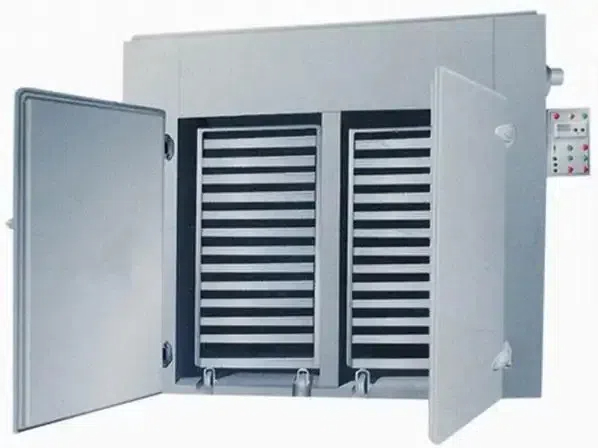

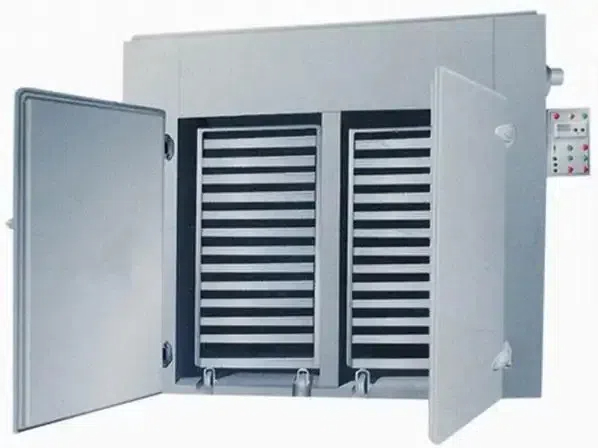

A heat pump dryer is an advanced drying system that utilizes a closed-loop system to recycle air and moisture. Unlike conventional dryers that vent hot air outside, heat pump dryers extract moisture from the food and condense it back into water, which can be drained away. This process not only conserves energy but also allows for more precise control over drying conditions.

Heat pump dryers operate at lower temperatures, making them suitable for drying heat-sensitive foods without compromising their quality. This technology is particularly beneficial in the food industry, where maintaining the nutritional value and flavor of dried products is paramount.

Advantages of Heat Pump Dryers in Food Drying

One of the most significant advantages of heat pump dryers is their energy efficiency. These dryers can reduce energy consumption by up to 50% compared to traditional drying methods. This efficiency translates into cost savings for food producers, making heat pump dryers an attractive investment.

Additionally, heat pump dryers are versatile and can be used to dry a wide range of food products, including fruits, vegetables, meats, and herbs. The ability to maintain lower drying temperatures helps preserve the nutritional content and flavor of the food, resulting in higher-quality dried products.

Disadvantages of Heat Pump Dryers

Despite their many benefits, heat pump dryers do have some drawbacks. The initial investment cost can be higher than that of conventional dryers, which may deter some small-scale producers. Furthermore, heat pump dryers typically have longer drying times, which can be a disadvantage in high-demand situations.

Maintenance is another consideration. While generally low, it requires regular cleaning of filters and monitoring of the water tank to ensure optimal performance.

The Food Drying Process

The food drying process involves several stages, including pre-treatment, drying, and post-drying handling. Pre-treatment may involve blanching or slicing food to enhance drying efficiency. During the drying phase, heat pump dryers circulate warm air around the food, gradually removing moisture.

Different drying methods exist, including freeze-drying, air drying, and sun drying. Heat pump dryers combine the benefits of these methods, offering a controlled environment that minimizes the risk of spoilage and ensures consistent results.

Applications of Heat Pump Dryers in the Food Industry

Heat pump dryers are increasingly being adopted in the food industry for both commercial and small-scale applications. For instance, large manufacturers use heat pump dryers to produce dried fruits and vegetables, while small-scale producers benefit from the technology's efficiency and quality preservation.

Case studies have shown that businesses utilizing heat pump dryers can achieve higher profit margins due to reduced energy costs and improved product quality. This technology is particularly advantageous for organic and specialty food producers who prioritize quality and sustainability.

Conclusion

Heat pump dryers represent a significant advancement in food drying technology, offering numerous benefits such as energy efficiency, versatility, and quality preservation. While there are some drawbacks, the advantages often outweigh the challenges, making heat pump dryers a valuable asset in the food industry. As technology continues to evolve, we can expect to see even more innovative applications of heat pump dryers in food preservation.

Frequently Asked Questions

1. What types of food can be dried using heat pump dryers?

Heat pump dryers can effectively dry fruits, vegetables, meats, and herbs, preserving their nutritional value and flavor.

2. How does a heat pump dryer compare to traditional drying methods?

Heat pump dryers are more energy-efficient and maintain better food quality, but they may take longer to dry food compared to traditional methods.

3. What is the maintenance like for heat pump dryers?

Maintenance typically involves regular cleaning of filters and ensuring the water tank is emptied, which is relatively straightforward.

4. Are heat pump dryers suitable for home use?

Yes, heat pump dryers can be used in home settings, especially for those interested in preserving food efficiently.

5. What is the cost difference between heat pump dryers and conventional dryers?

While heat pump dryers have a higher upfront cost, they offer long-term savings through energy efficiency.