Content Menu

● Understanding Heat Pump Dryers

● How Heat Pump Dryers Work

● Advantages of Heat Pump Dryers

● Applications in Food Drying

● Comparative Analysis with Traditional Dryers

● Challenges and Considerations

● Future Trends in Food Drying Technologies

● Conclusion

● FAQ

>> 1. What makes heat pump dryers more energy-efficient than traditional dryers?

>> 2. Can heat pump dryers be used for drying food?

>> 3. Are there any downsides to using heat pump dryers?

>> 4. How does the installation of a heat pump dryer differ from traditional dryers?

>> 5. What maintenance do heat pump dryers require?

● Citations:

In recent years, heat pump dryers have gained popularity as a more efficient alternative to traditional dryers. As a manufacturer of food drying machines, understanding the benefits of heat pump technology can inform your product development and marketing strategies. This article explores the advantages of heat pump dryers, particularly in the context of food drying applications, while also addressing their broader implications for energy efficiency and environmental sustainability.

Understanding Heat Pump Dryers

Heat pump dryers operate using a closed-loop system that recycles air rather than venting it outside. This innovative approach not only enhances energy efficiency but also provides a gentler drying process, making it suitable for various applications, including food drying.

How Heat Pump Dryers Work

Heat pump dryers utilize a heat exchanger to extract moisture from clothes or food products. The process involves the following steps:

1. Air Intake: The dryer pulls in ambient air.

2. Heating: The air is heated using a refrigerant system.

3. Moisture Extraction: The warm air passes through the drum, absorbing moisture from the items inside.

4. Condensation: The moist air is then routed through an evaporator where the moisture condenses and is collected.

5. Recycling: The now-dry air is reheated and cycled back into the drum to continue the drying process.

This cycle continues until the desired moisture level is achieved, making heat pump dryers highly efficient and effective.

Advantages of Heat Pump Dryers

The advantages of heat pump dryers over traditional dryers are numerous:

- Energy Efficiency: Heat pump dryers consume approximately 28% less energy compared to conventional dryers. This translates into significant cost savings on electricity bills over time.

- Gentle Drying: Operating at lower temperatures makes heat pump dryers gentler on fabrics and food products. This reduces wear and tear on materials and helps maintain quality, which is particularly important for food preservation.

- Versatile Installation: Unlike traditional vented dryers that require extensive ductwork, heat pump dryers can be installed in various locations without the need for external venting. This flexibility is ideal for small spaces or facilities where installation options are limited.

- Environmental Impact: By using less energy, heat pump dryers contribute to lower carbon emissions, making them a more environmentally friendly choice. This aligns with global efforts to promote sustainability within the food processing industry.

- Reduced Risk of Mold: Traditional dryers vent moist air outside, which can lead to humidity issues in surrounding areas. Heat pump dryers mitigate this risk by condensing moisture internally.

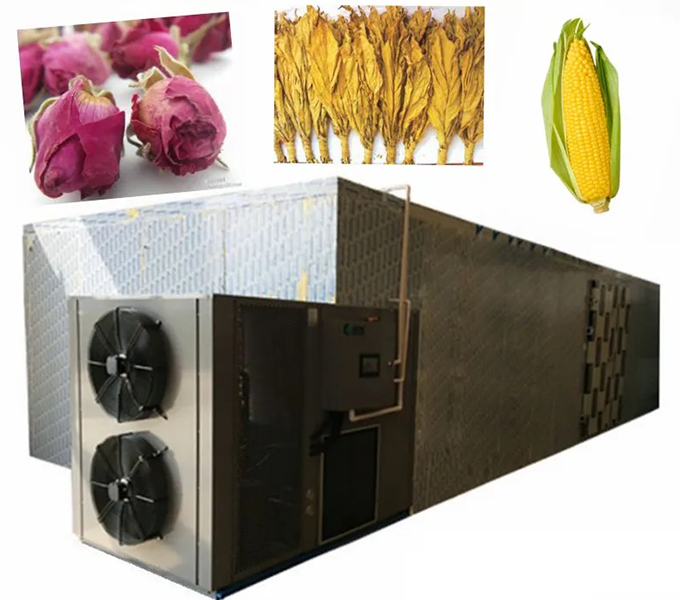

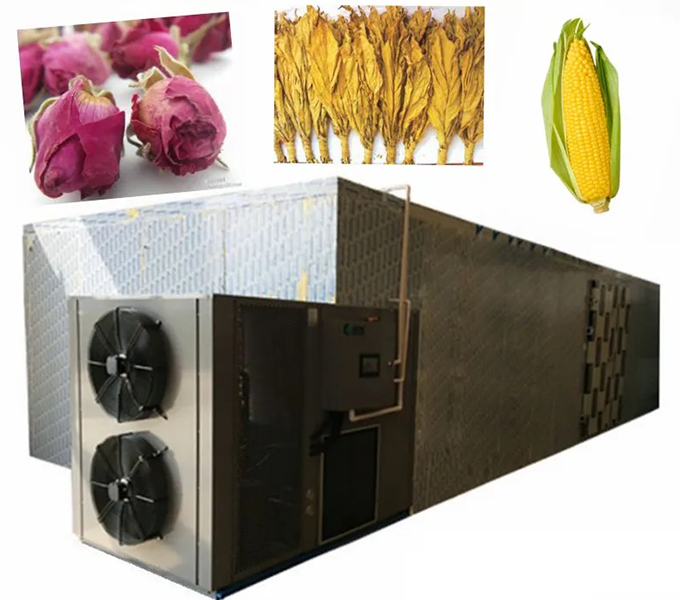

Applications in Food Drying

For food manufacturers and processors, heat pump technology presents several unique advantages:

- Preservation of Nutrients: Lower drying temperatures help retain more nutrients in dried foods compared to traditional methods that may use higher temperatures. Nutrient preservation is crucial for maintaining the health benefits of dried fruits, vegetables, and herbs.

- Consistent Quality: The controlled environment within a heat pump dryer allows for uniform drying, reducing the risk of uneven moisture levels that can lead to spoilage or quality degradation. This consistency is vital for brands looking to maintain quality across batches.

- Energy Savings: For large-scale food production facilities, the energy savings associated with heat pump technology can significantly reduce operational costs. By decreasing energy consumption, businesses can allocate resources more effectively elsewhere.

- Extended Shelf Life: Dried foods processed with heat pump technology often have longer shelf lives due to reduced moisture content and improved preservation methods. This aspect is particularly appealing to retailers and consumers alike.

Comparative Analysis with Traditional Dryers

To better understand the advantages of heat pump dryers, it's helpful to compare them directly with traditional dryers:

| Feature | Heat Pump Dryer | Traditional Dryer |

| Energy Consumption | Lower (up to 28% less) | Higher (more energy-intensive) |

| Operating Temperature | Lower (gentler on materials) | Higher (can damage delicate items) |

| Installation Flexibility | More versatile (no venting required) | Limited (requires ductwork) |

| Environmental Impact | More eco-friendly | Higher carbon footprint |

| Maintenance Needs | Regular filter cleaning | Less frequent but more complex |

This table illustrates how heat pump dryers outperform traditional models in several key areas, making them a compelling choice for both consumers and manufacturers.

Challenges and Considerations

While heat pump dryers offer many benefits, there are some challenges to consider:

- Longer Drying Times: Due to their lower operating temperatures, heat pump dryers may take longer to dry items compared to traditional models. This could impact production schedules in high-volume environments. However, many users find that the quality benefits outweigh this drawback.

- Higher Initial Costs: The upfront investment for heat pump technology can be higher than traditional systems. However, this cost is often offset by long-term savings on energy bills and maintenance.

- Maintenance Requirements: Regular maintenance is essential to keep heat pump systems operating efficiently. This includes cleaning filters and ensuring proper airflow. Manufacturers should provide clear guidelines on maintenance practices to ensure longevity and performance.

Future Trends in Food Drying Technologies

As technology continues to evolve, several trends are emerging within the realm of food drying:

- Smart Technology Integration: Many modern heat pump dryers are being equipped with smart technology that allows users to monitor and control drying processes remotely via mobile apps. This feature adds convenience and efficiency by enabling real-time adjustments based on specific needs.

- Sustainability Initiatives: With an increasing focus on sustainability in food production, manufacturers are investing in technologies that reduce waste and energy consumption. Heat pump technology aligns perfectly with these initiatives by offering an eco-friendly solution.

- Customization Options: As consumer preferences shift towards personalized products, manufacturers are exploring ways to customize drying processes based on specific food types or desired outcomes. Heat pump systems can be adapted easily for various applications.

- Enhanced Research and Development: Ongoing research into improving heat transfer efficiency and reducing costs will likely lead to even more advanced models in the future, further solidifying their place in both residential and commercial markets.

Conclusion

Heat pump dryers represent a significant advancement in drying technology, offering numerous advantages over traditional methods. Their energy efficiency, gentle drying capabilities, versatility in installation, and positive environmental impact make them an excellent choice for both residential and commercial applications—particularly within the food processing industry.

As manufacturers continue to innovate within this space, understanding these benefits will be crucial for developing competitive products that meet the needs of modern consumers who prioritize sustainability and efficiency.

FAQ

1. What makes heat pump dryers more energy-efficient than traditional dryers?

Heat pump dryers recycle air within a closed-loop system, using approximately 28% less energy than conventional models that vent hot air outside.

2. Can heat pump dryers be used for drying food?

Yes! Heat pump dryers are ideal for food drying as they operate at lower temperatures, preserving nutrients while ensuring consistent quality.

3. Are there any downsides to using heat pump dryers?

The main downsides include longer drying times compared to traditional models and higher initial costs; however, these can be mitigated by energy savings over time.

4. How does the installation of a heat pump dryer differ from traditional dryers?

Heat pump dryers do not require external venting or ductwork, allowing for flexible installation in various locations without significant modifications.

5. What maintenance do heat pump dryers require?

Regular maintenance includes cleaning filters and ensuring proper airflow within the system to maintain efficiency and prolong lifespan.

Citations:

[1] https://elephantenergy.com/heat-pump-dryer-vs-electric-dryer-whats-right-for-you/

[2] https://www.aztecappliance.com/blog/pros-cons-of-heat-pump-dryer

[3] https://www.ike.cn/video.html

[4] https://www.youtube.com/watch?v=FKSgyjk_e3c

[5] https://www.bonprixelectromenagers.com/blogs/news/pros-and-cons-of-heat-pump-vs-traditional-dryers-5

[6] https://www.familyhandyman.com/article/heat-pump-dryer/

[7] https://www.youtube.com/watch?v=rR2G5UO-5Ms

[8] https://www.istockphoto.com/de/bot-wall?returnUrl=%2Fde%2Fphotos%2Ffood-dryer

[9] https://www.eastcoastappliance.com/blog/heat-pump-dryer-guide

[10] https://www.energystar.gov/products/clothes_dryers/heat-pump-dryer