Content Menu

● How Heat Pump Dryers Work

● Advantages of Heat Pump Dryers

● Applications in Food Drying

● Comparison with Traditional Drying Methods

● Future Trends in Heat Pump Technology

● Conclusion

● Frequently Asked Questions

>> 1. What is the main advantage of using a heat pump dryer?

>> 2. Can heat pump dryers be used for delicate fabrics?

>> 3. Do heat pump dryers require external venting?

>> 4. How do heat pump dryers compare to traditional dryers in terms of drying time?

>> 5. Are heat pump dryers suitable for food drying?

Heat pump dryers are an innovative solution for drying clothes efficiently and effectively. Unlike traditional dryers that expel hot air outside, heat pump dryers recycle air within a closed system, making them more energy-efficient and environmentally friendly. This article will explore the working principle of heat pump dryers, their advantages, and their applications in food drying, particularly in the context of your business as a manufacturer of food drying machines.

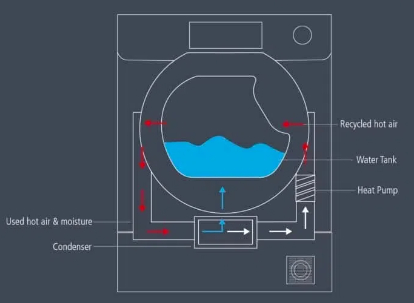

How Heat Pump Dryers Work

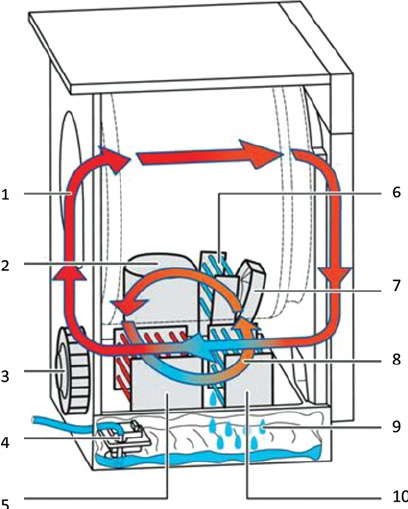

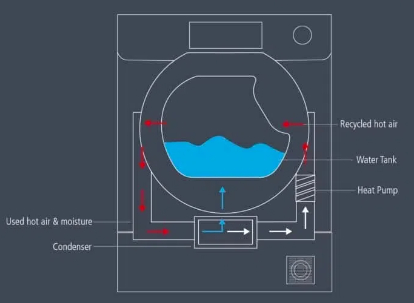

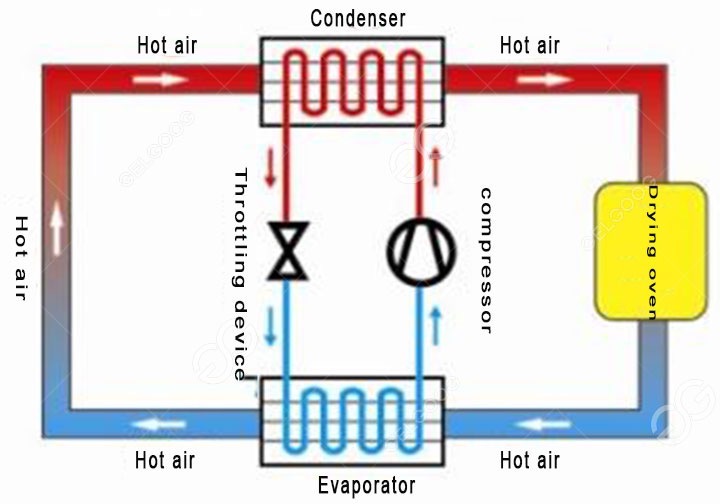

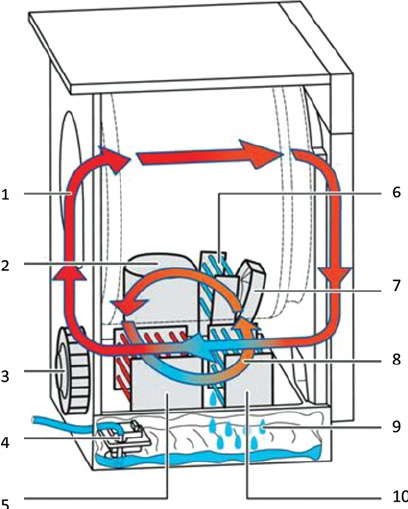

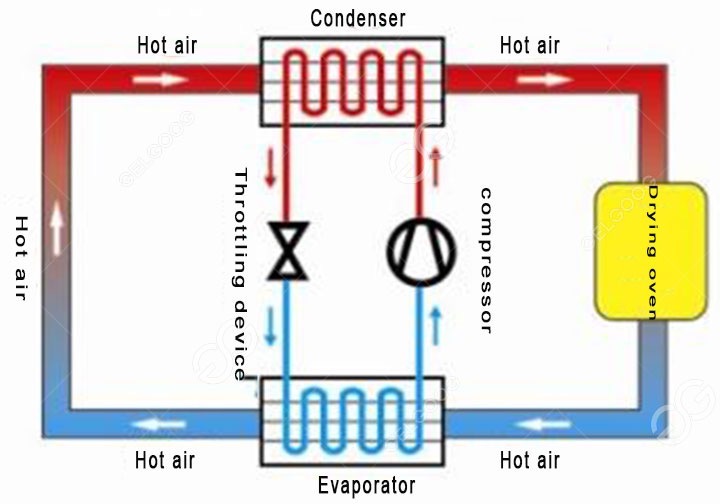

At the core of a heat pump dryer is a refrigeration cycle that involves four main components: the evaporator, compressor, condenser, and expansion valve. Here’s a breakdown of how these components work together to dry clothes:

1. Evaporator: The process begins in the evaporator, where the air from the dryer drum is drawn in. This air contains moisture from the wet clothes. The evaporator cools the air, causing the moisture to condense into water, which is collected in a reservoir or drained away.

2. Compressor: The now-dry air is then passed to the compressor. The compressor increases the pressure of the air, which raises its temperature. This hot air is essential for the drying process.

3. Condenser: The hot, pressurized air moves to the condenser, where it releases its heat into the dryer drum. This heat warms the air inside the drum, allowing it to absorb moisture from the clothes. The cycle continues as the air is recirculated.

4. Expansion Valve: After passing through the condenser, the air is cooled and depressurized by the expansion valve before returning to the evaporator to repeat the cycle.

This closed-loop system allows heat pump dryers to operate at lower temperatures than traditional dryers, which helps to protect delicate fabrics and reduce energy consumption.

Advantages of Heat Pump Dryers

1. Energy Efficiency: Heat pump dryers use significantly less energy compared to conventional dryers. They can save up to 50% on energy costs, making them an economical choice for both households and businesses.

2. Gentle on Fabrics: The lower drying temperatures are less harsh on clothes, reducing wear and tear. This is particularly beneficial for delicate fabrics that might be damaged in a traditional dryer.

3. No Ventilation Required: Since heat pump dryers do not expel air outside, they can be installed in various locations without the need for external venting. This flexibility is advantageous for both residential and commercial settings.

4. Environmentally Friendly: By using less energy and recycling air, heat pump dryers have a lower carbon footprint compared to traditional dryers.

5. Versatile Applications: Beyond laundry, heat pump technology can be applied in food drying processes, making it suitable for your business in manufacturing food drying machines.

Applications in Food Drying

Heat pump dryers are increasingly being used in the food industry for drying fruits, vegetables, and other food products. The benefits of using heat pump technology in food drying include:

1. Preservation of Nutrients: The lower drying temperatures help retain the nutritional value of food products, which is crucial for health-conscious consumers. Traditional drying methods often involve high temperatures that can degrade vitamins and minerals.

2. Improved Quality: Heat pump dryers can produce high-quality dried products with better texture and flavor compared to traditional drying methods. The controlled environment allows for uniform drying, preventing the over-drying of some parts while others remain moist.

3. Energy Savings: The energy efficiency of heat pump dryers translates to lower operational costs for food manufacturers. This is particularly important in a competitive market where profit margins can be tight.

4. Reduced Risk of Contamination: The closed-loop system minimizes the risk of contamination from external sources, ensuring that the dried food products maintain their quality and safety.

5. Scalability: Heat pump dryers can be designed to accommodate various scales of production, from small artisanal operations to large industrial facilities. This adaptability makes them suitable for a wide range of food processing businesses.

Comparison with Traditional Drying Methods

When comparing heat pump dryers to traditional drying methods, several key differences emerge:

1. Temperature Control: Traditional dryers often operate at high temperatures, which can lead to uneven drying and nutrient loss. Heat pump dryers, on the other hand, maintain a consistent and lower temperature, ensuring that food retains its quality.

2. Energy Consumption: Traditional dryers can consume a significant amount of energy, especially when used frequently. Heat pump dryers are designed to be energy-efficient, making them a more sustainable option for long-term use.

3. Installation Requirements: Traditional dryers typically require venting to the outside, which can limit installation options. Heat pump dryers can be placed in various locations without the need for external venting, providing greater flexibility.

4. Cost of Operation: While the initial investment in a heat pump dryer may be higher, the long-term savings on energy bills and improved product quality can offset these costs, making them a wise investment for food manufacturers.

Future Trends in Heat Pump Technology

As technology continues to advance, the future of heat pump dryers looks promising. Some trends to watch for include:

1. Smart Technology Integration: The incorporation of smart technology into heat pump dryers will allow for better monitoring and control of the drying process. This can lead to improved efficiency and product quality.

2. Sustainability Focus: With increasing awareness of environmental issues, manufacturers are likely to focus on developing even more energy-efficient and eco-friendly heat pump dryers.

3. Customization Options: As the demand for specialized food products grows, manufacturers may offer customizable heat pump dryers tailored to specific food drying needs, enhancing versatility in food processing.

4. Research and Development: Ongoing research into heat pump technology will likely lead to innovations that improve performance, reduce costs, and expand applications in various industries beyond food drying.

Conclusion

Heat pump dryers represent a significant advancement in drying technology, offering numerous benefits for both laundry and food drying applications. Their energy efficiency, gentle drying capabilities, and versatility make them an excellent choice for manufacturers and consumers alike. As your business continues to provide OEM services for food drying machines, understanding the principles and advantages of heat pump technology will be crucial in meeting the needs of your clients and staying competitive in the market.

Frequently Asked Questions

1. What is the main advantage of using a heat pump dryer?

The main advantage is energy efficiency, as heat pump dryers use significantly less energy than traditional dryers.

2. Can heat pump dryers be used for delicate fabrics?

Yes, heat pump dryers operate at lower temperatures, making them gentle on delicate fabrics.

3. Do heat pump dryers require external venting?

No, heat pump dryers do not require external venting, allowing for flexible installation options.

4. How do heat pump dryers compare to traditional dryers in terms of drying time?

While heat pump dryers may take slightly longer to dry clothes, the energy savings and fabric care benefits often outweigh this factor.

5. Are heat pump dryers suitable for food drying?

Yes, heat pump dryers are increasingly used in food drying applications due to their ability to preserve nutrients and improve product quality.