Content Menu

● Understanding Heat Pump Dryers

● Advantages of Heat Pump Dryers

● Comparison with Traditional Dryers

● The Role of Technology in Food Drying

● Enhanced Nutritional Retention

● Environmental Impact

● Cost Considerations

● Case Studies and Applications

● Future Prospects

● Conclusion

● FAQ

>> 1. What is a heat pump dryer?

>> 2. How does a heat pump dryer work?

>> 3. Are heat pump dryers more expensive than traditional dryers?

>> 4. Can I use a heat pump dryer for all types of food?

>> 5. Do heat pump dryers require special installation?

● Citations:

In the realm of food drying technology, heat pump dryers have emerged as a revolutionary solution, particularly for industrial applications. As a manufacturer of food drying machines, understanding the efficiency and functionality of heat pump dryers compared to traditional dryers is vital for optimizing production processes. This article explores the workings of heat pump condenser dryers, their advantages over traditional dryers, and their significance in the food processing industry.

Understanding Heat Pump Dryers

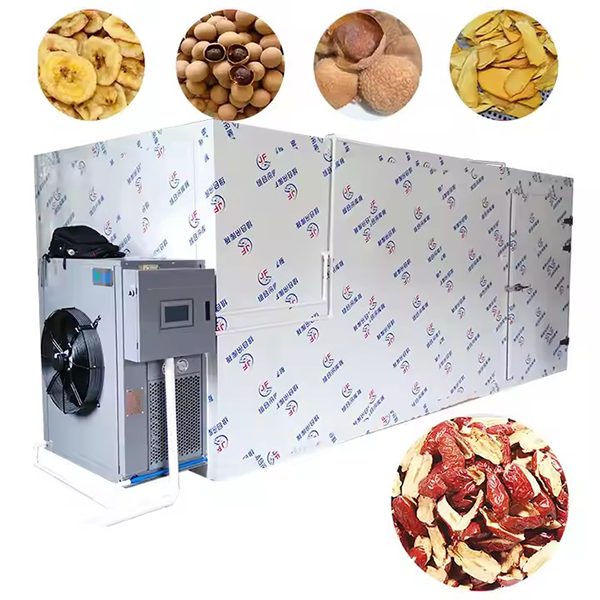

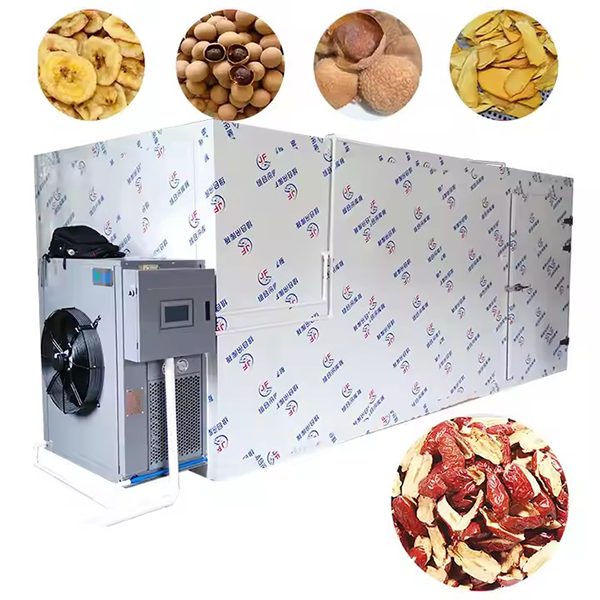

Heat pump dryers utilize a sophisticated system that operates similarly to an air conditioner or refrigerator. They work by extracting moisture from food products while recycling the warm air generated during the drying process.

Key Components:

- Compressor: Pressurizes refrigerant to release heat.

- Evaporator Coils: Absorb moisture from the air.

- Condenser Coils: Release heat back into the drying chamber.

- Fans: Circulate air evenly throughout the drying chamber.

This closed-loop system allows for efficient moisture removal without the need for external venting, making it ideal for various food products.

Advantages of Heat Pump Dryers

Heat pump dryers offer several advantages over traditional drying methods:

- Energy Efficiency: Heat pump dryers consume significantly less energy compared to traditional dryers. They can use up to 50% less energy per load, translating to lower operational costs and reduced environmental impact.

- Gentle Drying Process: Operating at lower temperatures (typically around 50°C), heat pump dryers prevent damage to delicate food items, preserving their nutritional value and texture. This is crucial for products like fruits and vegetables that can easily lose quality under high heat.

- Uniform Drying: Advanced air circulation systems ensure even drying across all trays, reducing the risk of hot spots and ensuring consistent quality in the final product. This uniformity is essential for maintaining product integrity and customer satisfaction.

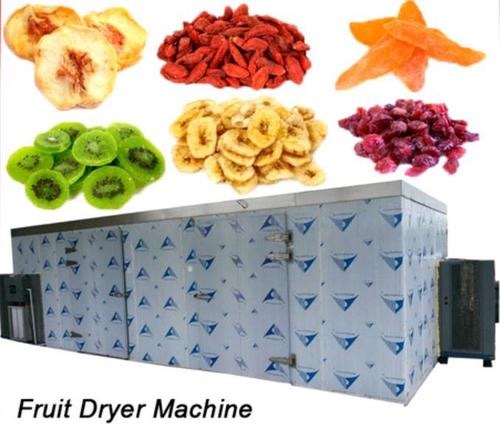

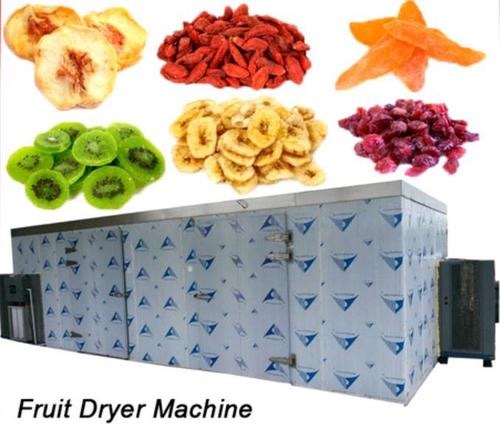

- Versatility: Heat pump dryers can handle a wide variety of foods, including fruits, vegetables, meats, and herbs. Their adjustable settings allow for tailored drying processes based on specific product requirements.

Comparison with Traditional Dryers

To better understand the efficiency of heat pump dryers, let's compare them with traditional drying methods:

| Feature | Heat Pump Dryer | Traditional Dryer |

| Energy Consumption | Up to 50% less per load | Higher energy usage |

| Operating Temperature | Around 50°C | 70-75°C |

| Drying Time | Longer (15-30 minutes more) | Shorter |

| Moisture Extraction | Recycles warm air | Expels moist air externally |

| Product Quality Preservation | Excellent | Moderate |

As illustrated in the table above, while heat pump dryers may require longer drying times, their energy efficiency and ability to preserve product quality make them a superior choice for many applications.

The Role of Technology in Food Drying

Modern heat pump dryers incorporate advanced technology that enhances their functionality:

- Programmable Controls: Users can set specific drying times and temperatures based on the type of food being processed. This flexibility allows for optimal results tailored to different products.

- Real-Time Monitoring: Many systems now feature sensors that provide real-time data on temperature and humidity levels within the drying chamber. This capability ensures that conditions remain optimal throughout the drying process.

- Remote Access: Some models allow users to control and monitor their operations remotely via smartphones or computers, enhancing convenience and operational efficiency.

Enhanced Nutritional Retention

One of the significant benefits of heat pump drying technology is its ability to retain nutrients in food products. Traditional drying methods often expose foods to high temperatures that can degrade vitamins and minerals. In contrast, heat pump dryers operate at lower temperatures, which helps preserve essential nutrients such as vitamin C and antioxidants. This retention is particularly important for health-conscious consumers who seek high-quality dried fruits and vegetables without compromising nutritional value.

Environmental Impact

The environmental benefits of using heat pump dryers cannot be overstated. These systems are designed to be eco-friendly by utilizing less energy and reducing greenhouse gas emissions compared to conventional dryers. As industries move towards sustainable practices, adopting heat pump technology aligns with global efforts to combat climate change while maintaining production efficiency.

Cost Considerations

While the initial investment in a heat pump dryer may be higher than that for traditional models, the long-term savings are substantial. The reduced energy consumption leads to lower utility bills over time. Additionally, because these dryers are more efficient in moisture removal, they can expedite production cycles, allowing manufacturers to process more product within shorter time frames.

Case Studies and Applications

Numerous case studies highlight the effectiveness of heat pump dryers in various applications:

1. Fruit Drying: A study conducted on apple slices demonstrated that using a heat pump dryer not only reduced energy consumption by 40% but also improved color retention compared to hot air drying methods.

2. Herbs and Spices: In another case involving herbs like basil and oregano, heat pump drying preserved volatile oils better than traditional methods, resulting in enhanced flavor profiles in dried products.

3. Meat Products: For meat dehydration processes, heat pump technology has been shown to reduce microbial growth while maintaining texture and flavor integrity—crucial factors for consumer acceptance.

Future Prospects

The future of food processing will likely see increased adoption of hybrid technologies that combine heat pump systems with other innovative drying methods such as microwave-assisted or infrared drying. These combinations can further enhance efficiency while maintaining product quality. As research continues into optimizing these systems for various food types, manufacturers will benefit from improved processes that meet consumer demands for both quality and sustainability.

Conclusion

Heat pump condenser dryers represent a significant advancement in food drying technology. Their energy efficiency, gentle drying capabilities, and advanced features make them an excellent choice for manufacturers looking to optimize their production processes while maintaining high product quality. As the demand for energy-efficient solutions continues to grow in the food processing industry, investing in heat pump technology will likely yield substantial long-term benefits.

FAQ

1. What is a heat pump dryer?

A heat pump dryer is an appliance that uses a refrigeration cycle to dry clothes or food by recycling warm air instead of venting it outside.

2. How does a heat pump dryer work?

It works by drawing in humid air from the drum, extracting moisture through evaporator coils, then reheating and recirculating dry air back into the drum.

3. Are heat pump dryers more expensive than traditional dryers?

While they may have a higher initial purchase price, heat pump dryers save money over time due to lower energy consumption.

4. Can I use a heat pump dryer for all types of food?

Yes, heat pump dryers are versatile and can effectively dry various foods including fruits, vegetables, meats, and herbs.

5. Do heat pump dryers require special installation?

No special installation is needed; they do not require venting outside and can be placed in any suitable location within your facility.

Citations:

[1] http://www.ijstr.org/final-print/jan2021/Conventional-And-Advanced-Food-drying-Technology-A-Current-Review.pdf

[2] https://vn.dryers-dehydrators.com/info/advantage-of-food-heat-pump-dryer-81163580.html

[3] http://sciencebeingjournal.com/sites/default/files/Octa%20J.%20Biosci.%20Vol.%2010%20(2)124-133_0.pdf

[4] https://ijsra.net/sites/default/files/IJSRA-2024-0222.pdf

[5] https://pmc.ncbi.nlm.nih.gov/articles/PMC3550996/

[6] https://annals.fih.upt.ro/pdf-full/2016/ANNALS-2016-1-34.pdf

[7] https://pmc.ncbi.nlm.nih.gov/articles/PMC3550864/

[8] https://pmc.ncbi.nlm.nih.gov/articles/PMC7554907/

[9] https://www.mdpi.com/2076-3417/13/19/10597

[10] https://www.tandfonline.com/doi/full/10.1080/15538362.2021.1911746