Content Menu

● The Science Behind Negative Pressure Drying

● JIMU's Proprietary Negative Pressure Technology

>> Advanced Vacuum Generation

>> Precision Temperature Control

>> Customizable Airflow Patterns

>> Intelligent Monitoring and Control

● Applications Across the Food Industry

>> Fruit and Vegetable Processing

>> Meat and Seafood Drying

>> Grain and Cereal Processing

>> Herb and Spice Drying

● Case Study: JIMU's Impact on a Major Snack Manufacturer

● The Environmental Advantage

● Customization and Scalability

● Global Support and Service

● Future Innovations

● The JIMU Advantage: A Closer Look

>> Precision Engineering

>> Advanced Materials

>> Modular Design

● Energy Efficiency: A Deeper Dive

>> Heat Recovery Systems

>> Variable Frequency Drives

>> Insulation Technology

● Quality Assurance and Food Safety

>> Reduced Contamination Risk

>> Uniform Drying for Consistent Quality

>> Gentle Processing for Nutrient Retention

● Industry 4.0 Integration

>> IoT Connectivity

>> Data Analytics

>> Predictive Maintenance

● Sustainability Beyond Energy Efficiency

>> Water Conservation

>> Reduced Food Waste

>> Eco-Friendly Manufacturing

● Conclusion

● Frequently Asked Questions

>> 1. How does negative pressure drying differ from traditional drying methods?

>> 2. What types of food products are best suited for JIMU's negative pressure dryers?

>> 3. How does JIMU's negative pressure technology impact energy consumption?

>> 4. Can JIMU's negative pressure dryers be integrated into existing production lines?

>> 5. What maintenance is required for JIMU's negative pressure drying systems?

● Citations:

JIMU, a leading Chinese manufacturer of food drying equipment, has revolutionized the industry with its innovative negative pressure design. This cutting-edge technology sets JIMU apart from competitors and offers significant advantages for food processing companies worldwide. Let's explore the unique features of JIMU's negative pressure food dryers and why they are becoming increasingly popular among global food manufacturers.

The Science Behind Negative Pressure Drying

Negative pressure drying, also known as vacuum pressure or suction drying, is an advanced technique that utilizes pressure differentials to remove moisture from food products efficiently. Unlike traditional positive pressure systems that blow hot air onto food items, JIMU's negative pressure design creates a partial vacuum within the drying chamber, effectively "pulling" moisture out of the food.

This approach offers several key benefits:

1. More uniform drying

2. Lower drying temperatures

3. Reduced risk of contamination

4. Improved energy efficiency

5. Better preservation of food quality and nutrients

JIMU's Proprietary Negative Pressure Technology

JIMU has developed a proprietary negative pressure system that takes this concept to the next level. Their design incorporates several innovative features:

Advanced Vacuum Generation

JIMU's dryers use high-efficiency vacuum pumps to create a consistent negative pressure environment throughout the drying chamber. This ensures optimal moisture removal from even the most challenging food products.

Precision Temperature Control

The system maintains precise temperature control, allowing for lower drying temperatures that preserve the nutritional value and sensory qualities of the food being processed.

Customizable Airflow Patterns

JIMU's engineers have developed adjustable airflow patterns within the drying chamber, enabling processors to fine-tune the drying process for different food types and shapes.

Intelligent Monitoring and Control

State-of-the-art sensors and control systems continuously monitor and adjust drying parameters in real-time, ensuring consistent results and maximum efficiency.

Applications Across the Food Industry

JIMU's negative pressure dryers have found applications in various sectors of the food industry:

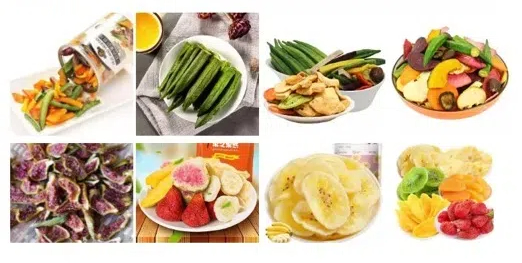

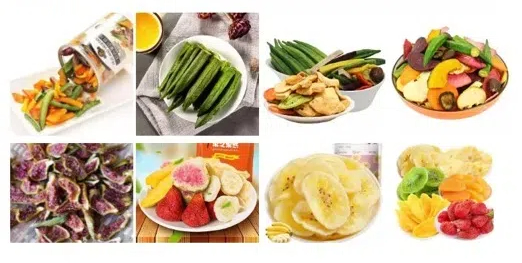

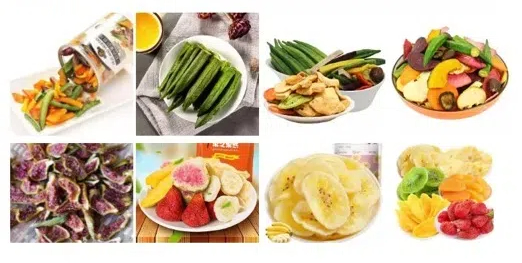

Fruit and Vegetable Processing

The gentle drying process is ideal for preserving the color, flavor, and nutritional content of fruits and vegetables. Processors can create high-quality dried products with extended shelf life.

Meat and Seafood Drying

JIMU's technology allows for the efficient drying of meat and seafood products while maintaining their texture and taste. This is particularly valuable for producing jerky, dried fish, and other preserved meat products.

Grain and Cereal Processing

The uniform drying achieved through negative pressure is perfect for grains and cereals, ensuring consistent moisture content throughout the batch.

Herb and Spice Drying

Delicate herbs and spices benefit from the low-temperature drying capabilities, preserving their essential oils and aromatic compounds.

Case Study: JIMU's Impact on a Major Snack Manufacturer

To illustrate the real-world benefits of JIMU's negative pressure dryers, let's examine a case study involving a leading international snack food company.

The company, which produces a wide range of dried fruit and vegetable snacks, was facing challenges with product quality and energy costs using traditional drying methods. After implementing JIMU's negative pressure drying system, they experienced:

- A 30% reduction in energy consumption

- Improved product texture and flavor retention

- 25% faster drying times

- Increased production capacity

- Reduced product waste due to more consistent drying

These improvements led to significant cost savings and a boost in product quality, helping the manufacturer maintain its competitive edge in the market.

The Environmental Advantage

JIMU's commitment to sustainability is evident in their negative pressure drying technology. The increased energy efficiency and reduced drying times translate to a smaller carbon footprint for food processing operations. Additionally, the lower operating temperatures mean less heat is released into the environment, further reducing the overall environmental impact.

Customization and Scalability

One of the key strengths of JIMU's negative pressure dryers is their adaptability to different production scales and requirements. The company offers a range of models suitable for small-batch processors up to large-scale industrial operations. Each system can be customized to meet specific product needs and production volumes.

Global Support and Service

As an OEM supplier to international food dryer brands, wholesalers, and manufacturers, JIMU provides comprehensive support and service worldwide. This includes:

- Installation and commissioning

- Operator training

- Preventive maintenance programs

- Remote diagnostics and troubleshooting

- Spare parts supply

This global support network ensures that JIMU's customers can maximize the benefits of their negative pressure drying systems, regardless of their location.

Future Innovations

JIMU continues to invest in research and development to further enhance its negative pressure drying technology. Some areas of focus include:

- Integration of artificial intelligence for predictive maintenance and process optimization

- Development of hybrid drying systems combining negative pressure with other technologies

- Exploration of new materials for improved energy efficiency and durability

These ongoing innovations promise to keep JIMU at the forefront of food drying technology for years to come.

The JIMU Advantage: A Closer Look

Precision Engineering

At the heart of JIMU's negative pressure design is precision engineering. Every component of the drying system is carefully designed and manufactured to exacting standards. This attention to detail ensures optimal performance and longevity of the equipment.

Advanced Materials

JIMU utilizes cutting-edge materials in the construction of their dryers. From corrosion-resistant alloys to high-performance polymers, these materials contribute to the durability and efficiency of the systems. The use of advanced materials also allows for better thermal management and easier cleaning, crucial factors in food processing environments.

Modular Design

JIMU's negative pressure dryers feature a modular design that offers several advantages:

1. Easy scalability to meet changing production needs

2. Simplified maintenance and part replacement

3. Flexibility to adapt to different product types

4. Reduced downtime during upgrades or repairs

This modular approach allows food processors to invest in a system that can grow and evolve with their business.

Energy Efficiency: A Deeper Dive

The energy efficiency of JIMU's negative pressure dryers is one of their most compelling features. Let's explore this aspect in more detail:

Heat Recovery Systems

JIMU incorporates advanced heat recovery systems into their dryers. These systems capture and recycle heat that would otherwise be lost, significantly reducing overall energy consumption.

Variable Frequency Drives

The use of variable frequency drives (VFDs) in JIMU's dryers allows for precise control of motor speeds. This results in optimized energy use based on the specific drying requirements of each product batch.

Insulation Technology

JIMU employs state-of-the-art insulation materials and designs to minimize heat loss during the drying process. This not only improves energy efficiency but also contributes to more consistent drying conditions within the chamber.

Quality Assurance and Food Safety

JIMU's negative pressure design plays a crucial role in ensuring food safety and quality:

Reduced Contamination Risk

The closed system of negative pressure drying minimizes the risk of external contamination. This is particularly important for sensitive food products or those requiring strict hygiene standards.

Uniform Drying for Consistent Quality

The even distribution of negative pressure throughout the drying chamber results in more uniform moisture removal. This consistency is key to producing high-quality dried foods with reliable texture and flavor profiles.

Gentle Processing for Nutrient Retention

The lower drying temperatures made possible by JIMU's negative pressure technology help preserve heat-sensitive nutrients, vitamins, and bioactive compounds in food products.

Industry 4.0 Integration

JIMU is at the forefront of Industry 4.0 adoption in food drying technology:

IoT Connectivity

JIMU's negative pressure dryers can be equipped with Internet of Things (IoT) capabilities, allowing for remote monitoring and control of drying processes.

Data Analytics

Advanced data analytics tools integrated into JIMU's systems provide valuable insights into drying performance, energy usage, and product quality metrics.

Predictive Maintenance

By leveraging machine learning algorithms, JIMU's dryers can predict maintenance needs before issues arise, minimizing downtime and optimizing performance.

Sustainability Beyond Energy Efficiency

While energy efficiency is a key component of JIMU's sustainability efforts, the company's commitment to environmental responsibility extends further:

Water Conservation

JIMU's negative pressure drying technology requires minimal water usage compared to some traditional drying methods, contributing to water conservation efforts in food processing.

Reduced Food Waste

The precise control and consistency offered by JIMU's dryers help reduce product waste due to over-drying or uneven moisture content.

Eco-Friendly Manufacturing

JIMU implements sustainable practices in their own manufacturing processes, including the use of recycled materials and energy-efficient production techniques.

Conclusion

JIMU's negative pressure design represents a significant leap forward in food drying technology. By harnessing the power of vacuum pressure, JIMU has created a system that offers superior drying performance, energy efficiency, and product quality. As the food industry continues to evolve, JIMU's innovative approach positions them as a leader in meeting the challenges of modern food processing.

For food manufacturers looking to improve their drying processes, JIMU's negative pressure dryers offer a compelling solution that can drive efficiency, quality, and sustainability. With its commitment to ongoing innovation and global support, JIMU is poised to remain a trusted partner for food processors worldwide.

Frequently Asked Questions

1. How does negative pressure drying differ from traditional drying methods?

Negative pressure drying creates a partial vacuum within the drying chamber, effectively "pulling" moisture out of food products. This differs from traditional methods that use positive pressure to blow hot air onto the food. The negative pressure approach results in more uniform drying, lower operating temperatures, and better preservation of food quality.

2. What types of food products are best suited for JIMU's negative pressure dryers?

JIMU's negative pressure dryers are versatile and can handle a wide range of food products. They are particularly well-suited for fruits, vegetables, meats, seafood, grains, cereals, herbs, and spices. The gentle drying process makes them ideal for products that are sensitive to heat or require careful moisture removal to maintain quality.

3. How does JIMU's negative pressure technology impact energy consumption?

JIMU's negative pressure dryers typically reduce energy consumption by 20-30% compared to traditional drying methods. This is achieved through more efficient moisture removal, lower operating temperatures, and shorter drying times. The energy savings can lead to significant cost reductions for food processors.

4. Can JIMU's negative pressure dryers be integrated into existing production lines?

Yes, JIMU designs its negative pressure dryers with flexibility in mind. They can be integrated into most existing production lines with minimal disruption. JIMU's engineering team works closely with clients to ensure seamless integration and optimal performance within their specific production environments.

5. What maintenance is required for JIMU's negative pressure drying systems?

JIMU's negative pressure dryers are designed for reliability and ease of maintenance. Regular maintenance typically includes cleaning, filter replacement, and inspection of seals and vacuum components. JIMU provides comprehensive maintenance guidelines and offers preventive maintenance programs to ensure optimal performance and longevity of the equipment.

Citations:

[1] https://www.danthermgroup.com/uk/insights/insulation-drying-taking-a-negative-approach-to-deliver-positive-results

[2] https://eureka.patsnap.com/patent-CN108413735A

[3] https://unimac.com/international/zh-hans/

[4] https://patents.google.com/patent/CN201828125U/en

[5] https://www.reycosystems.com/solutions/negative-pneumatic-system/

[6]https://www.aptgroup.com/cn/%E5%85%AC%E5%8F%B8/%E6%A1%88%E4%BE%8B/%E7%BE%8E%E8%AF%BA%E7%94%B5%E5%99%A8%EF%BC%8C%E6%8D%B7%E5%85%8Buni%C4%8Dov%E5%B7%A5%E5%8E%82

[7] https://www.dryeratech.com/the-role-of-negative-pressure-in-penetration-type-dryers.html

[8] https://alliedcleanrooms.com/what-is-a-negative-pressure-room/

[9] https://www.lncc.edu.cn/wlx/pdf2/dzjc.pdf