Content Menu

● Introduction

● Understanding Heat Pump Dryers

>> How Heat Pump Dryers Work

● Efficiency Ratings and Power Consumption

>> Key Factors Influencing Efficiency Ratings

>> Power Consumption of Heat Pump Dryers

>> Energy Efficiency Ratings

● Benefits of Using Heat Pump Dryers for Food Processing

>> 1. Energy Efficiency

>> 2. Cost Savings

>> 3. Quality Preservation

>> 4. Environmental Impact

● Comparison with Traditional Drying Methods

● Conclusion

● Frequently Asked Questions

>> 1. What is the average power consumption of a heat pump dryer?

>> 2. How does a heat pump dryer compare to a conventional dryer in terms of drying time?

>> 3. Are there specific maintenance requirements for heat pump dryers?

>> 4. Can heat pump dryers be used for all types of food products?

>> 5. What should I consider when purchasing a heat pump dryer?

Introduction

In the world of food processing, efficiency and energy consumption are crucial factors that can significantly impact operational costs and sustainability. One of the most innovative technologies in this field is the heat pump dryer. This article delves into the efficiency ratings of heat pump dryers, focusing on their power consumption, benefits, and how they compare to traditional drying methods.

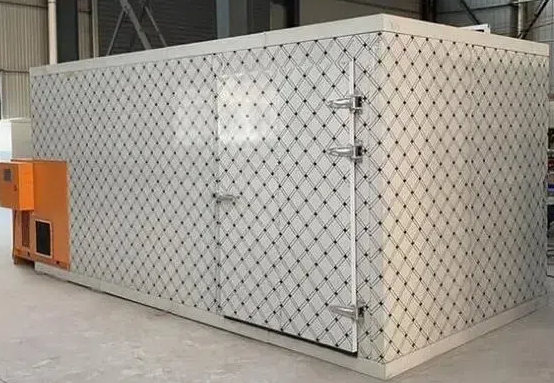

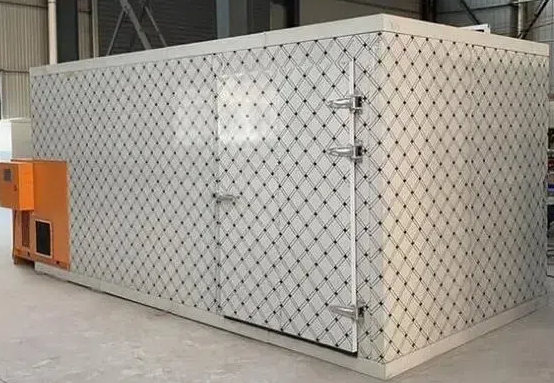

Understanding Heat Pump Dryers

Heat pump dryers utilize a refrigeration cycle to dry products efficiently. Unlike conventional dryers that expel hot air, heat pump dryers recycle warm air, significantly reducing energy consumption. This method not only conserves energy but also maintains the quality of the food being dried.

How Heat Pump Dryers Work

Heat pump dryers operate by extracting moisture from food products using a combination of heat exchange and air circulation. The process involves:

1. Evaporation: Moisture from the food is evaporated using warm air.

2. Condensation: The moisture-laden air is then cooled, causing the water vapor to condense.

3. Recycling: The heat generated during condensation is reused to warm incoming air, creating a closed-loop system.

Efficiency Ratings and Power Consumption

Key Factors Influencing Efficiency Ratings

When evaluating heat pump dryers, several factors contribute to their efficiency ratings:

- Energy Consumption: Measured in kilowatt-hours (kWh), this indicates how much electricity the dryer uses during operation.

- Drying Capacity: The amount of product that can be dried in a single cycle affects overall efficiency.

- Temperature Control: Advanced models feature precise temperature controls that optimize drying without wasting energy.

- Humidity Levels: Efficient moisture removal reduces drying time and energy use.

Power Consumption of Heat Pump Dryers

The power consumption of heat pump dryers is notably lower than that of traditional dryers. Typically, these dryers consume about 50% less energy compared to conventional models. This reduction translates to significant cost savings over time, making them an attractive option for food manufacturers.

Energy Efficiency Ratings

Heat pump dryers are often rated using various efficiency metrics:

- Energy Factor (EF): This measures the drying efficiency based on energy used per load.

- Coefficient of Performance (COP): This ratio indicates how effectively a dryer converts electrical energy into useful drying output.

Higher ratings in these categories signify better performance and lower power consumption.

Benefits of Using Heat Pump Dryers for Food Processing

1. Energy Efficiency

The primary advantage of heat pump dryers is their energy efficiency. By recycling heat, they minimize electricity use while maintaining optimal drying conditions.

2. Cost Savings

Lower power consumption leads to reduced operational costs. Over time, these savings can offset the initial investment in more advanced drying technology.

3. Quality Preservation

Heat pump dryers operate at lower temperatures compared to traditional methods, preserving the nutritional quality and flavor of food products.

4. Environmental Impact

With rising concerns about energy consumption and environmental sustainability, using heat pump dryers can significantly reduce a company's carbon footprint.

Comparison with Traditional Drying Methods

| Feature | Heat Pump Dryer | Traditional Dryer |

|--------------------------|----------------------------------|---------------------------------|

| Energy Consumption | Low (50% less than traditional) | High |

| Temperature Control | Precise | Limited |

| Quality Preservation | High | Moderate |

| Operational Cost | Lower | Higher |

This comparison highlights why many food manufacturers are shifting towards heat pump technology for their drying needs.

Conclusion

Heat pump dryers represent a significant advancement in food processing technology. Their superior energy efficiency and lower power consumption make them an ideal choice for manufacturers looking to reduce costs while maintaining product quality. As the industry moves towards more sustainable practices, investing in heat pump dryers can provide both economic and environmental benefits.

Frequently Asked Questions

1. What is the average power consumption of a heat pump dryer?

The average power consumption varies by model but generally ranges from 1 kWh to 3 kWh per cycle, significantly lower than traditional dryers.

2. How does a heat pump dryer compare to a conventional dryer in terms of drying time?

While drying times may be slightly longer due to lower temperatures, the overall efficiency and quality preservation make heat pump dryers preferable for many applications.

3. Are there specific maintenance requirements for heat pump dryers?

Yes, regular cleaning of filters and ensuring proper airflow are essential for maintaining efficiency and prolonging the life of the dryer.

4. Can heat pump dryers be used for all types of food products?

Most heat pump dryers are versatile and can handle various food types, including fruits, vegetables, and meats, although specific settings may be required for different products.

5. What should I consider when purchasing a heat pump dryer?

Consider factors such as energy efficiency ratings, capacity, temperature control features, and your specific drying needs to choose the right model for your operation.