Content Menu

● Understanding Heat Pump Dryers

>> Benefits of Heat Pump Dryers

● Key Considerations When Choosing a Heat Pump Dryer

>> 1. Capacity and Size

>> 2. Temperature Control

>> 3. Moisture Control

>> 4. Energy Efficiency Ratings

>> 5. Ease of Use and Maintenance

>> 6. Durability and Build Quality

>> 7. Cost and Return on Investment

>> 8. Manufacturer Reputation and Support

>> 9. Compliance with Food Safety Standards

>> 10. Customization Options

● Conclusion

● Frequently Asked Questions

>> 1. What is the main advantage of using a heat pump dryer for food processing?

>> 2. Can heat pump dryers be used for all types of food?

>> 3. How do I maintain a heat pump dryer?

>> 4. Are heat pump dryers more expensive than traditional dryers?

>> 5. What should I look for in terms of warranty and support?

When it comes to food processing, drying is a crucial step that can significantly affect the quality, shelf life, and safety of food products. As a manufacturer of food dryers in China, we understand the importance of selecting the right drying technology. One of the most efficient and innovative options available today is the heat pump dryer. This article will explore the key considerations when choosing a heat pump dryer for food processing, focusing on its benefits, features, and operational aspects.

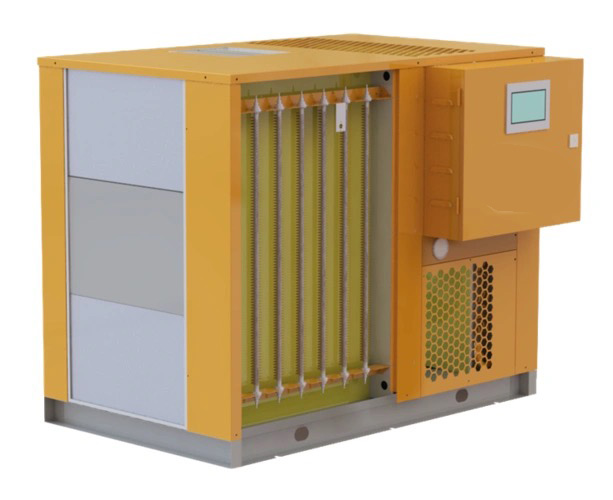

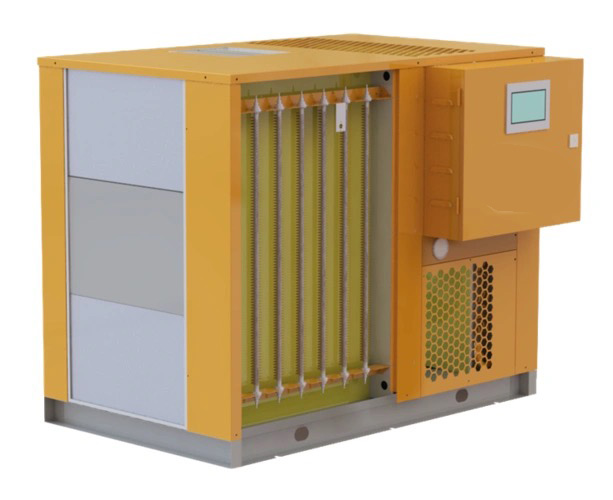

Understanding Heat Pump Dryers

Heat pump dryers utilize a closed-loop system that recycles heat, making them highly energy-efficient. Unlike traditional dryers that expel hot air and require constant energy input, heat pump dryers extract moisture from food while reusing the heat generated in the process. This not only reduces energy consumption but also maintains a consistent drying temperature, which is essential for preserving the nutritional value and flavor of food products.

Benefits of Heat Pump Dryers

1. Energy Efficiency: Heat pump dryers can reduce energy consumption by up to 50% compared to conventional drying methods. This is particularly beneficial for large-scale food processing operations where energy costs can be significant.

2. Consistent Drying: The ability to maintain a stable temperature throughout the drying process ensures that food products are dried evenly, preventing over-drying or under-drying.

3. Quality Preservation: By operating at lower temperatures, heat pump dryers help retain the color, flavor, and nutritional content of food, making them ideal for sensitive products like fruits, vegetables, and herbs.

4. Versatility: Heat pump dryers can be used for a wide range of food products, including meats, fish, fruits, and vegetables. This versatility makes them suitable for various applications in the food industry.

5. Environmentally Friendly: With lower energy consumption and reduced greenhouse gas emissions, heat pump dryers are a more sustainable option for food processing.

Key Considerations When Choosing a Heat Pump Dryer

1. Capacity and Size

When selecting a heat pump dryer, it is essential to consider the capacity that meets your production needs. Heat pump dryers come in various sizes, from small units suitable for artisanal producers to large industrial models designed for high-volume operations. Assess your production volume and choose a dryer that can handle your specific requirements without compromising efficiency.

2. Temperature Control

The ability to control the drying temperature is crucial for food quality. Look for heat pump dryers that offer precise temperature settings and monitoring capabilities. This feature allows you to adjust the drying conditions based on the type of food being processed, ensuring optimal results. For instance, drying herbs may require lower temperatures compared to drying meats, and having this flexibility can significantly enhance product quality.

3. Moisture Control

Effective moisture control is vital for preventing spoilage and ensuring product quality. Choose a heat pump dryer equipped with advanced moisture sensors that can automatically adjust the drying process based on the moisture content of the food. This feature helps maintain consistent drying conditions and reduces the risk of over-drying. Additionally, some models offer real-time monitoring, allowing operators to track moisture levels throughout the drying cycle.

4. Energy Efficiency Ratings

Energy efficiency is a significant factor in the operational costs of a heat pump dryer. Look for models with high energy efficiency ratings, which indicate lower energy consumption and reduced operating costs. Investing in an energy-efficient dryer can lead to substantial savings over time. Many manufacturers provide energy consumption data, which can help you compare different models and make an informed decision.

5. Ease of Use and Maintenance

Consider the user-friendliness of the heat pump dryer. Features such as intuitive controls, easy-to-read displays, and automated functions can simplify the drying process. Additionally, choose a model that is easy to clean and maintain, as regular maintenance is essential for optimal performance and longevity. Some advanced models even come with self-cleaning features, reducing the need for manual intervention.

6. Durability and Build Quality

The durability of the heat pump dryer is crucial, especially in a commercial setting. Look for models constructed from high-quality materials that can withstand the rigors of daily use. Stainless steel components are often preferred for their resistance to corrosion and ease of cleaning. A robust design not only extends the lifespan of the dryer but also ensures consistent performance over time.

7. Cost and Return on Investment

While the initial cost of a heat pump dryer may be higher than traditional dryers, it is essential to consider the long-term return on investment. Calculate potential energy savings, maintenance costs, and the value of improved product quality when evaluating the overall cost-effectiveness of the dryer. A thorough cost-benefit analysis can help you justify the investment and understand the financial implications.

8. Manufacturer Reputation and Support

Choose a reputable manufacturer with a proven track record in producing heat pump dryers. Research customer reviews and testimonials to gauge the reliability and performance of their products. Additionally, consider the level of customer support and service offered by the manufacturer, as this can be crucial for troubleshooting and maintenance. A manufacturer that provides comprehensive training and support can significantly enhance your operational efficiency.

9. Compliance with Food Safety Standards

Ensure that the heat pump dryer complies with relevant food safety regulations and standards. This is particularly important for food processing operations, as non-compliance can lead to legal issues and product recalls. Look for certifications that demonstrate adherence to safety and quality standards. Compliance not only protects your business but also builds trust with your customers.

10. Customization Options

Some manufacturers offer customization options for heat pump dryers, allowing you to tailor the equipment to your specific needs. This can include modifications to the drying chamber, control systems, and additional features that enhance functionality. Consider whether customization is necessary for your operation, as tailored solutions can improve efficiency and product quality.

Conclusion

Choosing the right heat pump dryer for food processing is a critical decision that can impact the quality, efficiency, and sustainability of your operations. By considering factors such as capacity, temperature control, energy efficiency, and manufacturer reputation, you can make an informed choice that meets your specific needs. Investing in a high-quality heat pump dryer not only enhances your production capabilities but also contributes to a more sustainable and environmentally friendly food processing industry.

Frequently Asked Questions

1. What is the main advantage of using a heat pump dryer for food processing?

The main advantage is energy efficiency, as heat pump dryers can significantly reduce energy consumption while maintaining consistent drying temperatures, preserving food quality.

2. Can heat pump dryers be used for all types of food?

Yes, heat pump dryers are versatile and can be used for a wide range of food products, including fruits, vegetables, meats, and herbs.

3. How do I maintain a heat pump dryer?

Regular maintenance includes cleaning the filters, checking for any blockages, and ensuring that the moisture sensors are functioning correctly. Following the manufacturer's maintenance guidelines is essential.

4. Are heat pump dryers more expensive than traditional dryers?

Yes, the initial cost of heat pump dryers is typically higher, but they offer long-term savings through reduced energy consumption and improved product quality.

5. What should I look for in terms of warranty and support?

Look for manufacturers that offer comprehensive warranties and reliable customer support to assist with any issues that may arise during operation.