Content Menu

● Introduction

● What is a Vented Dryer?

>> Advantages of Vented Dryers

>> Disadvantages of Vented Dryers

● What is a Heat Pump Dryer?

>> Advantages of Heat Pump Dryers

>> Disadvantages of Heat Pump Dryers

● Key Considerations When Choosing Between Vented and Heat Pump Dryers

>> 1. Energy Efficiency

>> 2. Product Type

>> 3. Space Limitations

>> 4. Initial Budget vs. Long-Term Costs

>> 5. Maintenance Requirements

● Additional Factors Affecting Your Decision

>> 1. Climate Considerations

>> 2. Production Volume

>> 3. Regulatory Compliance

>> 4. Technology Advancements

● Conclusion

● Frequently Asked Questions

>> 1. What is the main difference between a vented dryer and a heat pump dryer?

>> 2. Are heat pump dryers more energy-efficient than vented dryers?

>> 3. Can I use a heat pump dryer for all types of food products?

>> 4. Do I need special installation for a vented dryer?

>> 5. What are the maintenance needs for each type of dryer?

Introduction

In the food processing industry, drying is a crucial step that significantly impacts the quality, shelf life, and taste of the final product. As a manufacturer of food dryers, we understand the importance of selecting the right type of dryer for your specific needs. Among the various options available, vented and heat pump dryers are two popular choices. This article will explore the differences between these two types of dryers, their advantages and disadvantages, and what you should consider when choosing the right food dryer for your business.

What is a Vented Dryer?

A vented dryer operates by drawing in air from the environment, heating it, and then blowing it into the drying chamber. The moisture-laden air is expelled outside through a vent. This method is commonly used in many industrial applications due to its straightforward design and effectiveness in removing moisture from food products.

Advantages of Vented Dryers

- Faster Drying Times: Vented dryers typically offer quicker drying times compared to heat pump dryers due to their higher temperature settings. This can be particularly beneficial for businesses that require rapid processing to meet demand.

- Lower Initial Cost: Generally, vented dryers are less expensive to purchase and install than heat pump dryers. This makes them an attractive option for startups or smaller operations with limited budgets.

- Simplicity: The design and operation of vented dryers are relatively simple, making them easier to maintain. This simplicity can lead to lower operational costs in terms of maintenance labor and downtime.

Disadvantages of Vented Dryers

- Energy Inefficiency: Vented dryers can be less energy-efficient since they continuously draw in new air and expel heated air outside. This can lead to higher energy bills over time, especially in high-volume operations.

- Environmental Impact: The expulsion of warm air can lead to increased energy consumption and a larger carbon footprint. For businesses committed to sustainability, this can be a significant drawback.

- Space Requirements: Vented dryers require proper ventilation, which may limit installation options in certain facilities. Businesses located in urban areas or those with limited outdoor space may find it challenging to accommodate vented systems.

What is a Heat Pump Dryer?

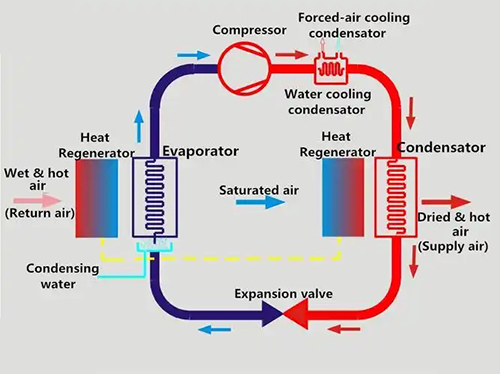

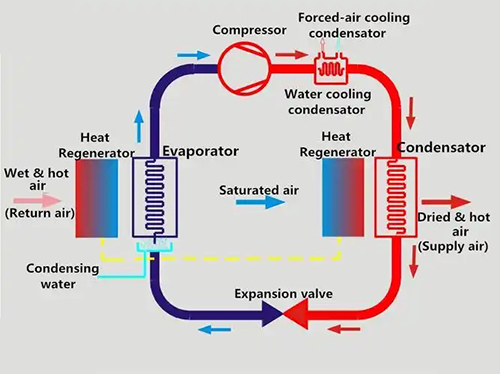

Heat pump dryers use a different technology that recycles hot air within the drying chamber. They operate by extracting moisture from the air and using a heat exchanger to warm it up again before recirculating it back into the chamber. This closed-loop system allows for more efficient moisture removal without expelling heated air outside.

Advantages of Heat Pump Dryers

- Energy Efficiency: Heat pump dryers are more energy-efficient than vented models because they recycle hot air, reducing overall energy consumption. This efficiency can lead to significant savings on utility bills over time.

- Lower Operating Costs: Although they may have a higher initial cost, heat pump dryers can lead to significant savings on energy bills over time. For businesses that prioritize long-term financial planning, this makes heat pump dryers an appealing choice.

- Gentler Drying Process: The lower temperatures used in heat pump drying can help preserve the quality and nutritional value of food products. This is particularly important for delicate items such as fruits and vegetables that may lose flavor or nutrients when exposed to high heat.

Disadvantages of Heat Pump Dryers

- Higher Initial Investment: The upfront cost for heat pump dryers is generally higher than that of vented dryers. For small businesses or those just starting out, this initial investment can be a barrier.

- Longer Drying Times: While they are efficient, heat pump dryers typically take longer to dry products compared to vented models. This could impact production schedules if not properly managed.

- Complex Maintenance: The technology involved in heat pump dryers can make maintenance more complicated and potentially more costly. Businesses must ensure they have access to qualified technicians who can perform necessary repairs.

Key Considerations When Choosing Between Vented and Heat Pump Dryers

When deciding between a vented or heat pump dryer for your food processing needs, consider the following factors:

1. Energy Efficiency

If your primary concern is energy consumption and long-term operating costs, a heat pump dryer may be the better option. However, if you need faster drying times and have immediate production demands, a vented dryer could be more suitable.

2. Product Type

Different food products require different drying techniques. For instance, delicate items such as fruits may benefit from the gentler approach of heat pump dryers, whereas bulkier items might be processed more efficiently with vented models. Understanding your product's characteristics will help you choose the right dryer.

3. Space Limitations

Consider your facility's layout. If space is limited or if proper ventilation is challenging to achieve, a heat pump dryer might be advantageous due to its closed-loop system that does not require external venting. Additionally, some heat pump models are designed to fit into tighter spaces without sacrificing performance.

4. Initial Budget vs. Long-Term Costs

Evaluate your budget for both initial investment and long-term operational costs. While vented dryers may have lower upfront costs, their higher energy consumption could lead to greater expenses over time. A thorough cost analysis will help you make an informed decision based on your financial situation.

5. Maintenance Requirements

Assess your ability to perform regular maintenance on your equipment. Vented dryers typically require simpler maintenance tasks compared to heat pump dryers which may involve more complex systems due to their technology. Ensure that your team has the necessary skills or access to service providers for ongoing maintenance needs.

Additional Factors Affecting Your Decision

In addition to the considerations mentioned above, other factors may influence your choice between vented and heat pump dryers:

1. Climate Considerations

The climate where your facility is located can also impact dryer performance. In humid environments, heat pump dryers may perform better as they effectively manage moisture levels without losing efficiency. Conversely, in dry climates, vented dryers might excel due to their ability to quickly expel moisture-laden air.

2. Production Volume

Your production volume will determine how often you need to run your dryer and how quickly you need it to operate. High-volume operations may benefit from the speed of vented dryers despite their inefficiencies, while lower-volume producers might find that heat pump dryers meet their needs without excessive energy costs.

3. Regulatory Compliance

Depending on your location and product type, there may be regulations governing food processing equipment and energy use standards. Make sure that whichever type of dryer you choose complies with local regulations regarding emissions and energy efficiency.

4. Technology Advancements

Keep an eye on advancements in drying technology as both vented and heat pump systems continue to evolve with new features aimed at improving efficiency and performance. Investing in newer technologies could provide long-term benefits as they often come with enhanced capabilities that improve overall productivity.

Conclusion

Choosing between a vented or heat pump dryer involves careful consideration of several factors including energy efficiency, product type, space limitations, budget constraints, maintenance requirements, climate considerations, production volume needs, regulatory compliance, and technological advancements. Each type has its unique advantages and disadvantages that can significantly impact your food processing operations.

Understanding these differences will help you make an informed decision that aligns with your business goals and operational needs. By evaluating your specific requirements against the features offered by each type of dryer—whether it's a traditional vented model or an innovative heat pump system—you can ensure that you select the best option for your food drying processes.

Frequently Asked Questions

1. What is the main difference between a vented dryer and a heat pump dryer?

The main difference lies in their operation; vented dryers expel moisture-laden air outside while heat pump dryers recycle hot air within a closed system for efficient moisture removal.

2. Are heat pump dryers more energy-efficient than vented dryers?

Yes, heat pump dryers are generally more energy-efficient as they recycle hot air instead of expelling it outside, leading to lower energy consumption over time.

3. Can I use a heat pump dryer for all types of food products?

While heat pump dryers are suitable for many types of food products due to their gentler drying process, certain bulkier items may dry faster in a vented dryer.

4. Do I need special installation for a vented dryer?

Yes, vented dryers require proper ventilation to expel moist air outside; this may limit installation options depending on your facility's layout.

5. What are the maintenance needs for each type of dryer?

Vented dryers typically require simpler maintenance tasks compared to heat pump dryers which may involve more complex systems due to their technology.