Content Menu

● The Evolution of Food Dehydration

● Introduction of Heat Pump Technology

● Advantages of Heat Pump Dryers

● Applications in Food Processing

● Technological Advancements in Food Drying

● Benefits of Heat Pump Drying

● Environmental Impact

● Conclusion

● FAQs

>> 1. What is a heat pump dryer?

>> 2. How does a heat pump dryer work?

>> 3. What are the benefits of using a heat pump dryer for food?

>> 4. Can I use a heat pump dryer at home?

>> 5. When was the first heat pump dryer invented?

● Citations:

Food dehydration is an ancient preservation technique that has evolved significantly over the centuries, leading to the modern food drying machines we see today. Among these innovations, heat pump dryers have emerged as a revolutionary technology in food processing. This article will explore the history of food drying technology, focusing on heat pump dryers, their development, and their applications in the food industry.

The Evolution of Food Dehydration

Food dehydration is one of the oldest methods of food preservation, with practices dating back to 12,000 BCE. Ancient civilizations utilized natural sunlight to dry fruits, vegetables, and meats, allowing them to store food for extended periods without spoilage.

- Ancient Techniques: The Egyptians and Incas were among the first to harness the sun's energy for drying foods. They laid out food items in the sun to remove moisture, ensuring a stable food supply during droughts or famines.

- Automated Processes: The first automated dehydration process was developed in 1795 by French inventors Masson and Chollet. Their method involved heating food while extracting air to create a vacuum, significantly improving efficiency.

- Spray-Drying Invention: In 1872, Samuel Percy invented spray-drying, which atomized liquid into tiny droplets and dried them with hot air. This technique preserved nutritional content and flavor while extending shelf life.

- Freeze-Drying Development: In 1906, Jacques-Arsène d'Arsonval invented freeze-drying, a process that maintains food structure and nutritional value by sublimating frozen water directly into vapor.

Introduction of Heat Pump Technology

The concept of heat pumps dates back to the 1850s when they were used for heating and cooling applications. However, it wasn't until the late 20th century that heat pump technology was adapted for use in dryers.

- First Heat Pump Dryer: The first commercially available heat pump dryer was launched by Sanyo in 1987. This innovative appliance utilized a closed-loop system to recycle warm air and moisture from clothes, enhancing energy efficiency compared to traditional dryers.

- Working Principle: A heat pump dryer operates similarly to a refrigerator but in reverse. It extracts heat from the surrounding air and uses it to warm the air inside the dryer drum. Moist air is then passed through a condenser where moisture is collected, allowing dry air to be recirculated back into the drum.

Advantages of Heat Pump Dryers

Heat pump dryers offer several benefits over conventional drying methods:

- Energy Efficiency: They consume significantly less energy—up to 50% less than standard electric dryers—making them an environmentally friendly choice.

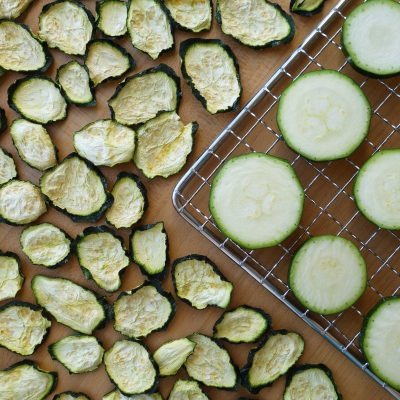

- Gentle Drying Process: The lower drying temperatures help preserve the quality of sensitive foods while preventing shrinkage or toughening.

- Versatility: Heat pump dryers can be used for various applications beyond laundry, including drying fruits and vegetables efficiently.

Applications in Food Processing

Heat pump technology has found applications in various sectors of food processing:

- Commercial Food Dehydration: Many manufacturers use heat pump dryers for large-scale dehydration processes due to their energy efficiency and ability to maintain product quality.

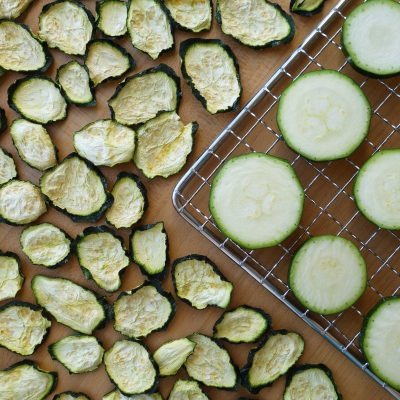

- Home Use: With the growing interest in home food preservation, many consumers are turning to heat pump dehydrators for making dried snacks like fruits and jerky.

Technological Advancements in Food Drying

Recent advancements in food drying technologies have focused on improving efficiency while maintaining product quality. These innovations include:

- Hybrid Drying Techniques: Combining heat pump drying with microwave or infrared drying can significantly reduce drying times while preserving nutrients. For instance, microwave-assisted heat pump drying utilizes electromagnetic radiation to generate internal heat within the product, enhancing drying efficiency[6][10].

- Smart Drying Systems: Integration of IoT technology allows for real-time monitoring and control of drying conditions. This ensures optimal temperature and humidity levels are maintained throughout the process[4][10].

- Non-Destructive Monitoring Technologies: These systems utilize computer vision and spectroscopy techniques to monitor moisture content and product quality during drying without damaging the food[4].

Benefits of Heat Pump Drying

The advantages of using heat pump dryers extend beyond energy savings:

- Cost-Effectiveness: Although initial investment costs may be higher than traditional methods, long-term savings on energy bills can offset these costs over time[3][8].

- Precise Temperature Control: Heat pump dryers can maintain specific temperature ranges that are optimal for different types of foods. This precision helps prevent nutrient loss and ensures consistent product quality[3][6].

- Increased Shelf Life: By effectively removing moisture from foods while preserving their structure and nutrients, heat pump dryers can significantly extend shelf life[3][7].

Environmental Impact

Heat pump dryers are also considered more environmentally friendly than traditional methods:

- Reduced Carbon Footprint: Their energy-efficient operation lowers overall electricity consumption, which is particularly beneficial when paired with renewable energy sources like solar power[8].

- Minimal Emissions: Unlike conventional dryers that may release pollutants into the atmosphere, heat pump systems operate with minimal environmental impact due to their closed-loop design[9][10].

Conclusion

The evolution of food drying technology has come a long way from ancient sun-drying methods to modern heat pump dryers. These appliances not only revolutionize how we preserve food but also contribute significantly to energy savings and sustainability in food processing. As advancements continue, we can expect even more innovative solutions that will enhance our ability to preserve foods efficiently while maintaining their quality.

FAQs

1. What is a heat pump dryer?

A heat pump dryer is an energy-efficient appliance that uses a refrigeration cycle to extract moisture from clothes or food items without venting hot air outside.

2. How does a heat pump dryer work?

It works by extracting heat from the surrounding air, using it to warm the air inside the drum where moist items are placed. The moist air is then condensed back into water while dry air is recirculated into the drum.

3. What are the benefits of using a heat pump dryer for food?

Heat pump dryers preserve nutritional content better than traditional methods due to lower temperatures and are more energy-efficient, reducing overall operating costs.

4. Can I use a heat pump dryer at home?

Yes! Many consumers use home models of heat pump dryers for dehydrating fruits, vegetables, and meats as part of their preservation practices.

5. When was the first heat pump dryer invented?

The first commercially available heat pump dryer was invented by Sanyo in 1987, marking a significant advancement in laundry technology.

Citations:

[1] https://www.frontiersin.org/research-topics/60295/food-drying-advancements-in-food-dehydration-and-preservation-approaches

[2] https://zeroenergyproject.com/2024/01/25/heat-pump-dryers-low-impact-laundry/

[3] https://vn.dryers-dehydrators.com/info/advantage-of-food-heat-pump-dryer-81163580.html

[4] https://www.mdpi.com/2227-9717/12/5/942

[5] https://www.energystar.gov/products/clothes_dryers/heat-pump-dryer

[6] http://sciencebeingjournal.com/sites/default/files/Octa%20J.%20Biosci.%20Vol.%2010%20(2)124-133_0.pdf

[7] https://pmc.ncbi.nlm.nih.gov/articles/PMC3550996/

[8] https://nef.org.uk/what-is-a-heat-pump-tumble-dryer/

[9] https://annals.fih.upt.ro/pdf-full/2016/ANNALS-2016-1-34.pdf

[10] https://pmc.ncbi.nlm.nih.gov/articles/PMC3550864/