Content Menu

● Understanding Food Dryers

● Types of Food Dryers

>> Condenser Dryers

>>> Advantages:

>>> Disadvantages:

>>> Ideal Applications:

>> Vented Dryers

>>> Advantages:

>>> Disadvantages:

>>> Ideal Applications:

>> Heat Pump Dryers

>>> Advantages:

>>> Disadvantages:

>>> Ideal Applications:

● Comparing Dryer Types

● Factors to Consider When Choosing a Dryer

● Additional Considerations

>> Regulatory Compliance

>> Scalability

>> User-Friendliness

● Maintenance Tips for Food Dryers

● Expanding on Applications of Food Dryers

>> Herbs & Spices

>> Meat Products

>> Snack Foods

● Energy Consumption Analysis

>> 1. Condenser Dryers

>> 2. Vented Dryers

>> 3. Heat Pump Dryers

● Conclusion Revisited

● Conclusion

● FAQ

>> 1. What is the main difference between condenser and vented dryers?

>> 2. Are heat pump dryers worth the investment?

>> 3. Can I install a vented dryer indoors?

>> 4. How often do I need to maintain my dryer?

>> 5. Which dryer is best for drying fruits?

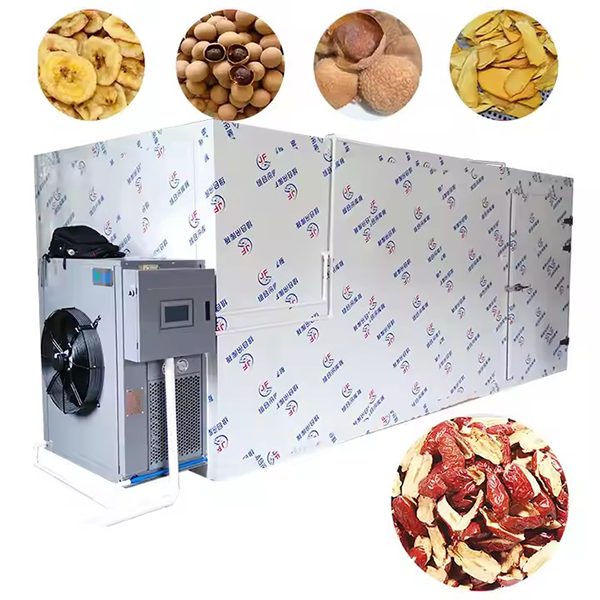

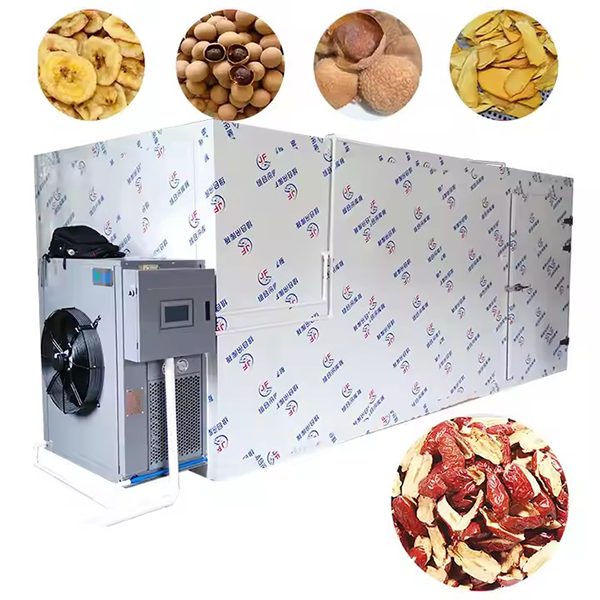

In the food processing industry, the choice of drying equipment is crucial for maintaining product quality and operational efficiency. As a manufacturer of food dryers in China, we understand the importance of selecting the right dryer type to meet your specific needs. This article will explore the three main types of dryers—condenser, vented, and heat pump—highlighting their features, benefits, and suitability for various applications in food drying.

Understanding Food Dryers

Food dryers are essential in preserving food by removing moisture content. The drying process not only extends shelf life but also enhances flavor and nutritional value. Choosing the right type of dryer can significantly impact your production efficiency and product quality.

Types of Food Dryers

Condenser Dryers

Condenser dryers operate by extracting moisture from the air inside the dryer and condensing it into water. This water is then collected in a tank or drained away.

Advantages:

- Energy Efficiency: These dryers use less energy compared to traditional vented models because they recycle hot air.

- No Ventilation Required: Since they do not expel hot air outside, they can be installed in various locations without needing external ventilation systems.

- Consistent Performance: They maintain a consistent temperature and humidity level, which is crucial for uniform drying.

Disadvantages:

- Initial Cost: The upfront investment can be higher than vented dryers.

- Maintenance Needs: Regular cleaning of the condenser unit is necessary to ensure optimal performance.

Ideal Applications:

Condenser dryers are suitable for drying fruits, vegetables, herbs, and other delicate food items that require careful moisture control.

Vented Dryers

Vented dryers work by expelling hot air outside while drawing in cooler air to replace it. This process helps to remove moisture from the food being dried.

Advantages:

- Faster Drying Times: The constant influx of fresh air allows for quicker moisture removal.

- Lower Initial Cost: Generally, vented dryers are less expensive than condenser models.

Disadvantages:

- Energy Consumption: They can be less energy-efficient due to heat loss during the drying process.

- Ventilation Requirements: These dryers require proper ventilation to function effectively, which may limit installation options.

Ideal Applications:

Vented dryers are best suited for larger-scale operations where speed is essential, such as drying bulk grains or meats.

Heat Pump Dryers

Heat pump dryers use a refrigeration cycle to extract moisture from food. They recycle heat within the system, making them highly energy-efficient.

Advantages:

- Energy Efficiency: Heat pump dryers consume significantly less energy compared to both condenser and vented models.

- Gentle Drying Process: They operate at lower temperatures, which helps preserve the quality of sensitive food items.

Disadvantages:

- Higher Initial Investment: The cost of heat pump technology can be prohibitive for some businesses.

- Longer Drying Times: While they are gentle on food products, this can result in longer drying times compared to vented options.

Ideal Applications:

Heat pump dryers are ideal for high-value products such as herbs, spices, and gourmet foods that require careful handling during the drying process.

Comparing Dryer Types

To help you make an informed decision about which dryer is best for your company, here's a comparison table summarizing key features:

| Feature | Condenser Dryer | Vented Dryer | Heat Pump Dryer |

| Energy Efficiency | High | Moderate | Very High |

| Initial Cost | High | Low | High |

| Maintenance | Moderate | Low | Moderate |

| Drying Speed | Moderate | Fast | Slow |

| Installation Flexibility | High | Low | Moderate |

Factors to Consider When Choosing a Dryer

When selecting a dryer for your food processing needs, consider the following factors:

- Type of Food Product: Different foods require different drying methods. Delicate items may benefit from condenser or heat pump dryers, while robust products may suit vented options.

- Production Volume: Higher production volumes may necessitate faster drying times provided by vented dryers. If your operation involves large batches of meat or grains that need quick processing, a vented dryer might be more appropriate.

- Energy Costs: Evaluate your local energy costs and choose a dryer that will minimize operating expenses over time. While heat pump dryers have higher upfront costs, their energy efficiency can lead to significant savings in the long run.

- Space Availability: Consider your facility's layout and whether you have space for ventilation if opting for a vented dryer. If space is limited or if you plan to install multiple units, condenser or heat pump dryers may offer more flexibility.

Additional Considerations

Regulatory Compliance

In many regions, food processing operations must comply with strict health and safety regulations. When choosing a dryer, ensure that it meets local standards regarding materials used in construction and operational safety features. This can include aspects like temperature controls and moisture monitoring systems that help maintain hygiene standards during the drying process.

Scalability

As your business grows, so too will your production needs. Consider whether the dryer you choose can scale with your operation. Some models allow for modular expansion or have adjustable settings that can accommodate varying batch sizes without compromising on quality or efficiency.

User-Friendliness

Ease of use is another factor that should not be overlooked. Look for models with intuitive controls that allow operators to easily adjust settings based on specific product requirements. Features like digital displays and automated cycles can greatly enhance operational efficiency and reduce training time for new staff members.

Maintenance Tips for Food Dryers

Proper maintenance is essential to prolonging the lifespan of your food dryer and ensuring consistent performance. Here are some key maintenance tips:

- Regular Cleaning: Keep all components clean from dust and debris. For condenser dryers, ensure that filters are regularly cleaned or replaced as needed to maintain airflow efficiency.

- Check Seals and Gaskets: Inspect seals and gaskets regularly for wear and tear. Replacing damaged seals can prevent energy loss and maintain optimal drying conditions.

- Monitor Performance: Keep an eye on drying times and product quality. Any significant changes may indicate that maintenance is required or that adjustments need to be made to settings.

- Professional Servicing: Schedule regular professional inspections to catch any potential issues early before they lead to costly repairs or downtime.

Expanding on Applications of Food Dryers

Food dryers play an integral role across various sectors within the food industry beyond just fruits and vegetables:

Herbs & Spices

Drying herbs like basil or thyme requires careful temperature control to preserve their essential oils and flavors. Condenser or heat pump dryers are preferred due to their gentle drying capabilities which help retain these qualities while ensuring thorough moisture removal.

Meat Products

For meat processing companies looking at jerky production or similar products, vented dryers offer rapid moisture removal which is crucial in preventing spoilage during long processes like curing or marinating before final drying stages.

Snack Foods

The growing trend towards healthy snacking has led many companies toward producing dried fruit snacks or vegetable chips. In this case:

- Condenser models can maintain flavor integrity while providing consistent results.

- Vented systems might be utilized when speed is prioritized over delicate handling since they allow bulk processing efficiently without compromising too much on quality if monitored correctly throughout cycles.

Energy Consumption Analysis

Understanding energy consumption patterns across different types of dryers can also guide decision-making:

1. Condenser Dryers

- Typically consume around 2–4 kWh per load depending on size.

- Ideal for operations focused on sustainability as they minimize wasted energy through recirculation.

2. Vented Dryers

- Can consume upwards of 5 kWh per load due to constant heating requirements.

- Best suited where quick turnaround times justify higher energy costs.

3. Heat Pump Dryers

- Generally range between 1–2 kWh per load.

- Highly efficient but initial setup costs should be weighed against long-term savings.

Conclusion Revisited

Choosing between condenser, vented, or heat pump dryers involves evaluating multiple factors including product type compatibility with each system's capabilities along with operational considerations like space requirements & potential scalability options based on future growth plans within your business model framework thus ensuring optimal performance while maximizing profitability through effective resource management strategies tailored specifically towards enhancing overall productivity levels across all aspects involved throughout production cycles effectively leading towards achieving desired outcomes efficiently.

Conclusion

Choosing the right type of dryer—be it condenser, vented, or heat pump—depends on various factors including product type, production volume, energy efficiency needs, and installation requirements. Each type has its unique advantages and disadvantages that can significantly impact your operations.

By understanding these differences and evaluating your specific needs carefully, you can make an informed decision that will enhance your production capabilities while ensuring high-quality dried food products. Investing in the right equipment not only improves efficiency but also contributes positively to your bottom line by reducing waste and improving product quality over time.

FAQ

1. What is the main difference between condenser and vented dryers?

Condenser dryers recycle air within the unit while removing moisture through condensation. Vented dryers expel hot air outside and draw in cooler air to facilitate drying.

2. Are heat pump dryers worth the investment?

Yes, heat pump dryers are highly energy-efficient and provide gentle drying at lower temperatures, making them ideal for high-value food products despite their higher initial cost.

3. Can I install a vented dryer indoors?

Vented dryers require proper ventilation to expel hot air outside; therefore, they are typically not suitable for indoor installation without appropriate ductwork.

4. How often do I need to maintain my dryer?

Maintenance frequency depends on usage but generally includes cleaning filters and checking components regularly to ensure optimal performance across all dryer types.

5. Which dryer is best for drying fruits?

Condenser dryers are often best suited for drying fruits due to their ability to maintain consistent temperature and humidity levels during the drying process.