Content Menu

● Understanding Heat Pump Dryers

● Advantages of Heat Pump Dryers

>> Increased Energy Efficiency

>> Cost-Effectiveness

>> Precise Temperature Control

>> Nutrient Retention

>> Reduced Drying Time

>> Extended Shelf Life

>> Environmental Impact

● Applications in Food Processing

● How Heat Pump Dryers Compare to Traditional Dryers

● The Technology Behind Heat Pump Dryers

● Benefits Beyond Energy Efficiency

● Challenges and Considerations

● Conclusion

● FAQs

>> 1. What is a heat pump dryer?

>> 2. How does a heat pump dryer save energy?

>> 3. Can I use a heat pump dryer for all types of foods?

>> 4. What are the benefits of using a heat pump dryer over traditional methods?

>> 5. Are there any downsides to using a heat pump dryer?

● Citations:

In the world of food processing, drying is a crucial step that affects the quality, shelf life, and nutritional value of food products. Among the various drying technologies available, heat pump dryers have emerged as a leading choice for food manufacturers due to their energy efficiency and effectiveness. This article explores the advantages of heat pump dryers, particularly in the context of food drying, while also addressing the question: Why use a heat pump dryer?

Understanding Heat Pump Dryers

Heat pump dryers operate on a principle similar to that of refrigeration systems. They use a closed-loop system to recycle air, which significantly reduces energy consumption compared to traditional dryers that vent hot air outside. Here's how they work:

1. Heat Extraction: The system extracts heat from the ambient air using a compressor and refrigerant.

2. Moisture Removal: Warm air circulates through the dryer, absorbing moisture from the food.

3. Condensation: The moisture is condensed into water and drained away, while the cooled air is reheated and recirculated.

This process allows heat pump dryers to maintain lower temperatures while effectively removing moisture, making them ideal for sensitive food products.

Advantages of Heat Pump Dryers

Increased Energy Efficiency

One of the most significant benefits of heat pump dryers is their energy efficiency. They consume about 30-50% less energy than conventional dryers because they recycle warm air instead of generating new heat. This not only leads to lower electricity bills but also reduces greenhouse gas emissions associated with energy production.

Cost-Effectiveness

While the initial investment in a heat pump dryer may be higher than traditional drying methods, the long-term savings on energy costs can be substantial. Businesses can expect a return on investment through reduced operational expenses over time.

Precise Temperature Control

Heat pump dryers offer precise control over temperature and humidity levels. This capability allows for optimal drying conditions tailored to specific food types, ensuring uniform drying and preserving product quality.

Nutrient Retention

Unlike high-temperature drying methods that can degrade vitamins and minerals, heat pump technology operates at lower temperatures, which helps retain the nutritional value of foods. This is particularly important for fruits and vegetables that are sensitive to heat.

Reduced Drying Time

Heat pump dryers can significantly reduce drying times due to their efficient heat transfer capabilities. This is crucial for perishable items that require quick processing to maintain freshness.

Extended Shelf Life

By effectively removing moisture without compromising quality, heat pump dryers help prolong the shelf life of food products. This minimizes spoilage and waste, making it an environmentally friendly option.

Environmental Impact

The eco-friendly operation of heat pump dryers contributes to sustainability in food processing. By reducing energy consumption and eliminating emissions associated with traditional drying methods, these systems support greener practices in the industry.

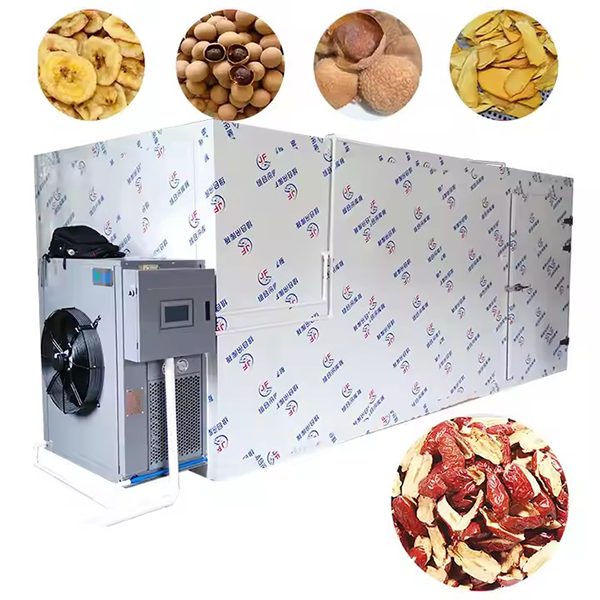

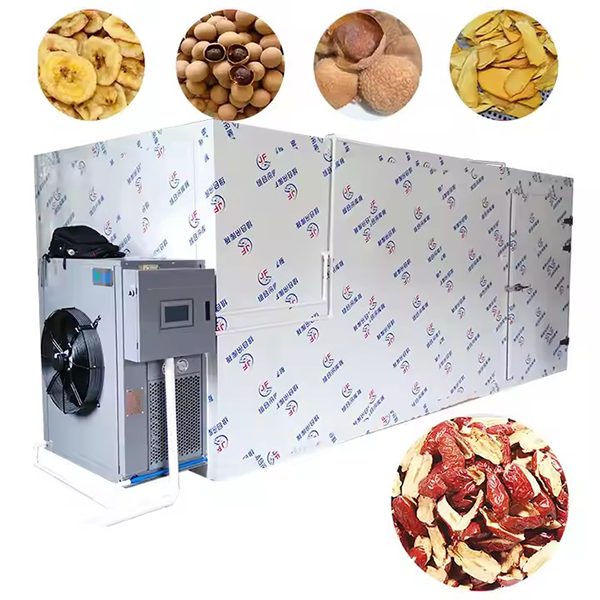

Applications in Food Processing

Heat pump dryers are versatile and can be used for a wide range of food products:

- Fruits: Apples, bananas, berries

- Vegetables: Carrots, tomatoes, herbs

- Meats: Jerky production

- Seafood: Fish drying

- Spices: Dehydrating herbs and spices for longer shelf life

How Heat Pump Dryers Compare to Traditional Dryers

| Feature | Heat Pump Dryer | Traditional Dryer |

| Energy Consumption | 30-50% less | Higher |

| Temperature Control | Precise | Limited |

| Nutrient Retention | High | Low |

| Drying Time | Reduced | Longer |

| Environmental Impact | Eco-friendly | Higher emissions |

The Technology Behind Heat Pump Dryers

Heat pump dryers utilize advanced technology that enables them to operate efficiently even in humid conditions. The system consists of several key components:

- Compressor: Compresses refrigerant gas to increase its temperature.

- Evaporator: Absorbs moisture from the air as it cools down.

- Condenser: Releases heat back into the air after moisture has been extracted.

- Expansion Valve: Regulates refrigerant flow within the system.

This combination allows for effective moisture removal while maintaining lower temperatures compared to conventional drying methods.

Benefits Beyond Energy Efficiency

In addition to energy savings, heat pump dryers offer several other benefits:

- Improved Product Quality: The gentle drying process helps preserve flavors, colors, and textures.

- Versatility in Applications: Suitable for various products including fruits, vegetables, meats, and herbs.

- Reduced Operating Costs: Lower energy consumption translates into reduced operational costs over time.

- Less Food Waste: By extending shelf life and maintaining quality, businesses can minimize spoilage and waste.

Challenges and Considerations

Despite their many advantages, there are some challenges associated with heat pump dryers:

- Initial Investment: The upfront cost can be higher compared to traditional dryers.

- Maintenance Requirements: Regular maintenance is essential to ensure optimal performance.

- Learning Curve: Operators may need training to understand how to set up and use these systems effectively.

Conclusion

In conclusion, heat pump dryers represent a significant advancement in food drying technology. Their ability to operate efficiently while preserving the quality and nutritional value of food makes them an ideal choice for manufacturers looking to optimize their processes. As businesses strive for sustainability and cost-effectiveness, adopting heat pump technology will likely become increasingly popular in the food industry.

The future of food processing will likely see more innovations aimed at improving efficiency while minimizing environmental impact. As consumers become more health-conscious and environmentally aware, manufacturers will need to adapt by investing in technologies like heat pump drying systems that align with these values.

FAQs

1. What is a heat pump dryer?

A heat pump dryer is an appliance that uses a closed-loop system to recycle warm air for drying clothes or food products efficiently without venting hot air outside.

2. How does a heat pump dryer save energy?

It saves energy by recycling heated air instead of generating new heat, consuming significantly less electricity compared to traditional vented dryers.

3. Can I use a heat pump dryer for all types of foods?

Yes, heat pump dryers are versatile and can effectively dry various foods including fruits, vegetables, meats, seafood, and herbs.

4. What are the benefits of using a heat pump dryer over traditional methods?

Benefits include lower energy consumption, precise temperature control, better nutrient retention, reduced drying times, and extended shelf life for dried products.

5. Are there any downsides to using a heat pump dryer?

While they may have higher upfront costs compared to conventional dryers, the long-term savings on energy bills typically offset this initial investment.

Citations:

[1] https://etsolutions.in/10-amazing-benefits-of-electrical-food-dehydrator-machines/

[2] https://vn.dryers-dehydrators.com/info/advantage-of-food-heat-pump-dryer-81163580.html

[3] https://annals.fih.upt.ro/pdf-full/2016/ANNALS-2016-1-34.pdf

[4] https://etsolutions.in/how-does-a-food-dehydrator-work-explore-the-benefits-of-food-dehydrators/

[5] http://sciencebeingjournal.com/sites/default/files/Octa%20J.%20Biosci.%20Vol.%2010%20(2)124-133_0.pdf

[6] https://pmc.ncbi.nlm.nih.gov/articles/PMC3550864/

[7] https://www.weforum.org/stories/2021/07/food-dehydrator-reducing-waste/

[8] https://www.linkedin.com/pulse/what-advantages-using-food-dryer-ella-huang

[9] https://www.tandfonline.com/doi/full/10.1080/15538362.2021.1911746

[10] https://www.dryeratech.com/what-are-the-benefits-of-using-a-heat-pump-dryer.html