Content Menu

● Introduction to Penetration Type Dryers

>> Key Features of Penetration Type Dryers

● Benefits of Penetration Type Dryers

>> Cost Savings

>> Environmental Sustainability

>> Versatility

>> Operational Efficiency and Maintenance

● Applications of Penetration Type Dryers

>> Nuts and Seeds

>> Spices

>> Fruits and Vegetables

● Future Developments and Trends

>> Integration of AI

>> Integration of Renewable Energy

>> Enhanced Automation

● Case Studies and Success Stories

● Conclusion

● Frequently Asked Questions

>> 1. What is the typical capacity of penetration type dryer machines?

>> 2. How energy-efficient are penetration type dryers compared to traditional dryers?

>> 3. What types of food products are suitable for penetration type dryers?

>> 4. Can penetration type dryers be customized for specific drying needs?

>> 5. How do penetration type dryers contribute to environmental sustainability?

● Citations:

In the rapidly evolving food processing industry, efficient and sustainable drying solutions are increasingly crucial for businesses seeking to optimize their operations while minimizing environmental impact. Among the various drying technologies available, penetration type dryers have emerged as a standout choice due to their unique combination of energy efficiency, versatility, and consistent drying results. This article will delve into the key features and advantages of JIMU's penetration type dryers, highlighting why they are a preferred option for food manufacturers worldwide.

Introduction to Penetration Type Dryers

Penetration type dryers are designed to efficiently dry products by utilizing a patented half-vacuum air duct system. This technology allows for even drying even when products are stacked together, making it ideal for large-scale operations. These dryers are energy-efficient, using only 25% of the electricity required by traditional dryers, and offer adjustable temperature settings from 18°C to 80°C, supporting hot drying, cool drying, and dehumidification functions.

Key Features of Penetration Type Dryers

1. Energy Efficiency: These dryers significantly reduce energy consumption compared to traditional models, making them cost-effective for businesses. By using less electricity, they not only reduce operational costs but also contribute to a more sustainable food processing environment.

2. Versatility: They can handle a wide range of products, from small batches to large quantities, with capacities ranging from 300 kg to 10 tons. This versatility makes them suitable for various industries, particularly in food processing.

3. Temperature Control: The ability to adjust temperatures ensures that products are dried without damage, preserving their quality. This feature is especially beneficial for sensitive food products that require precise temperature control to maintain nutritional value and texture.

4. Space Efficiency: The ability to stack products allows for more efficient use of space, making them ideal for facilities with limited area.

5. Consistent Drying: The half-vacuum system ensures uniform drying, reducing the risk of over-drying or under-drying.

Benefits of Penetration Type Dryers

Cost Savings

Penetration type dryers offer significant cost savings due to their energy efficiency. By using only 25% of the electricity required by traditional dryers, businesses can reduce their operational expenses and allocate resources more effectively.

Environmental Sustainability

The reduced energy consumption of these machines contributes to environmental sustainability. Lower energy usage means less carbon footprint, aligning with global efforts to reduce greenhouse gas emissions.

Versatility

These dryers are versatile and can handle a wide range of food products. Their adjustable temperature and humidity control features ensure that different products can be dried under optimal conditions.

Operational Efficiency and Maintenance

Penetration type dryers are designed with ease of maintenance in mind. The components are accessible, allowing for quick cleaning and replacement of parts when needed. This reduces downtime and ensures continuous operation.

Applications of Penetration Type Dryers

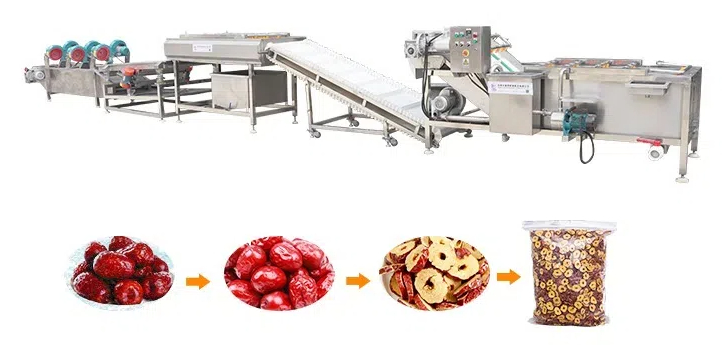

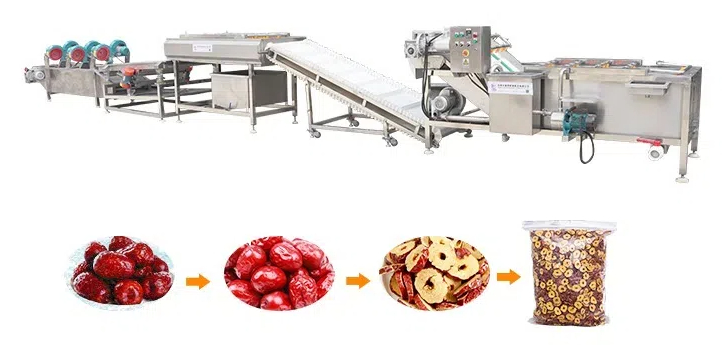

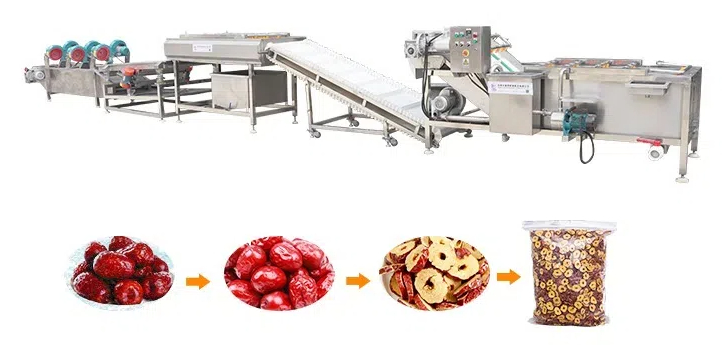

Penetration type dryers are ideal for drying various food products, including nuts, spices, seeds, beans, and other similar items. They can handle a wide range of food items that can be stacked together.

Nuts and Seeds

- Peanuts: Ideal for drying peanuts, which require precise temperature control to preserve their quality.

- Sunflower Seeds: Suitable for drying sunflower seeds, ensuring they retain their nutritional value.

- Pumpkin Seeds: Effective for drying pumpkin seeds, maintaining their texture and flavor.

Spices

- Cardamom: Suitable for drying cardamom, preserving its delicate flavors and aromas.

- Cloves: Ideal for drying cloves, maintaining their quality and aroma.

- Red Pepper: Effective for drying red pepper, ensuring consistent drying results.

Fruits and Vegetables

While penetration type dryers are primarily used for nuts and spices, they can also be adapted for drying certain fruits and vegetables, such as herbs and leafy greens. This versatility makes them valuable assets in diverse food processing environments.

Future Developments and Trends

As technology advances, the demand for more efficient and sustainable drying solutions is increasing. Penetration type dryers are well-positioned to meet these demands due to their energy efficiency and versatility. Future developments may include integrating smart technologies and renewable energy sources into drying systems, further enhancing their appeal to modern food processing facilities.

Integration of AI

Artificial intelligence can play a crucial role in optimizing drying processes by monitoring temperature, humidity, and product moisture levels in real-time. This allows for precise adjustments to ensure consistent quality and reduce waste. AI can also predict maintenance needs, reducing downtime and improving overall efficiency.

Integration of Renewable Energy

The integration of renewable energy sources, such as solar or wind power, can further enhance the sustainability of penetration type dryers. This not only reduces reliance on fossil fuels but also decreases operational costs over time.

Enhanced Automation

Future models may incorporate more advanced automation features, allowing for remote monitoring and control of drying processes. This would enable operators to manage multiple dryers from a central location, enhancing operational efficiency.

Case Studies and Success Stories

Several food processing companies have successfully integrated penetration type dryers into their operations, achieving significant improvements in efficiency and product quality. For example, a leading nut processing company reported a 30% reduction in energy costs and a 25% increase in production capacity after switching to penetration type dryers.

Conclusion

Penetration type dryers, particularly those offered by JIMU, stand out in the market due to their energy efficiency, versatility, and consistent drying results. These machines are ideal for large-scale food processing operations, offering significant cost savings and contributing to environmental sustainability. As the food industry continues to evolve, the integration of advanced technologies like AI will further enhance the efficiency and appeal of penetration type dryers.

Frequently Asked Questions

1. What is the typical capacity of penetration type dryer machines?

Penetration type dryer machines can handle capacities ranging from 300 to 10 tons, making them suitable for both small-scale and large-scale food drying operations.

2. How energy-efficient are penetration type dryers compared to traditional dryers?

Penetration type dryers use only 25% of the electricity required by traditional dryers, making them highly energy-efficient and cost-effective.

3. What types of food products are suitable for penetration type dryers?

These machines are ideal for drying nuts, spices, seeds, beans, and other similar products that can be stacked together.

4. Can penetration type dryers be customized for specific drying needs?

Yes, penetration type dryers can be customized to meet specific drying needs due to their adjustable temperature and humidity control features.

5. How do penetration type dryers contribute to environmental sustainability?

Penetration type dryers contribute to environmental sustainability by reducing energy consumption, which leads to a lower carbon footprint and aligns with global efforts to reduce greenhouse gas emissions.

Citations:

[1] https://www.dryeratech.com/key-features-of-penetration-type-dryer-machines-explained.html

[2] https://www.dryeratech.com/why-choose-a-penetration-type-dryer-for-your-business.html

[3] https://patents.google.com/patent/CN110207480A/zh

[4] https://www.dryeratech.com/penetration-type-dryer-machine.html

[5] https://www.dryeratech.com/energy-efficiency-the-advantage-of-penetration-type-dryers.html

[6] https://patents.google.com/patent/CN111575986A/zh

[7] https://www.jimdry.com/a-drying-innovations-unveiling-the-nut-dryer-machine-for-efficient-nut-processing.html

[8] https://www.aimheatpump.com/products-78591