Content Menu

● Introduction

● What are Hang Type Drying Machines?

● Key Features and Benefits

● Applications in Food Processing

● Advanced Technologies Integrated into Hang Type Drying Machines

● Customization Options

● Case Studies

● Conclusion

● FAQ

>> 1. What types of foods can be dried using hang type dryers?

>> 2. How do hang type dryers ensure even drying?

>> 3. What are the energy savings associated with heat pump technology?

>> 4. Can hang type dryers be customized?

>> 5. How do intelligent controls enhance operation?

● Citations:

Introduction

In the food processing industry, the drying method used for food products has a profound impact on the final product's quality, safety, and nutritional value. Traditional drying methods often fall short in maintaining these critical attributes, leading to concerns about spoilage, loss of flavor, and reduced nutritional content. However, hang type drying machines have emerged as a game-changing solution, revolutionizing how food products are dried and offering a multitude of benefits. This article explores the technology, advantages, and applications of hang type drying machines in food processing, providing a comprehensive overview for food drying machine brand owners, wholesalers, and manufacturers seeking OEM services.

What are Hang Type Drying Machines?

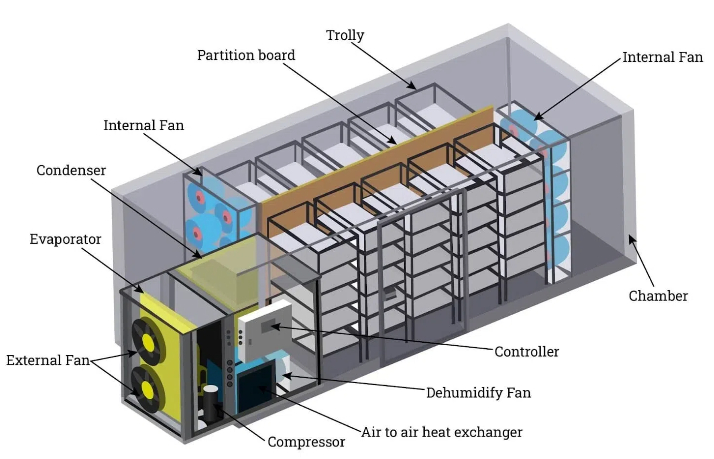

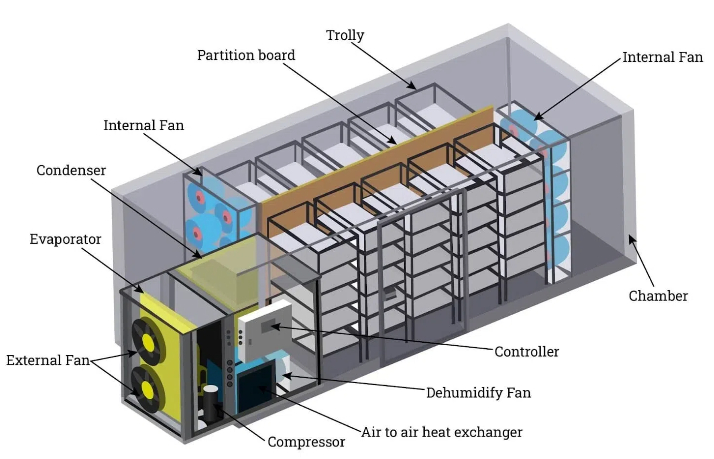

Hang type drying machines are specialized equipment designed to dry food products by suspending them from hangers within a controlled environment. This method is particularly effective for items such as noodles, sausages, fish, and herbs, where even drying is crucial to prevent spoilage and maintain texture. Unlike traditional tray dryers, hang type systems minimize contact points, reducing the risk of sticking or deformation.

Key Features and Benefits

1. Uniform Drying: Hang-type drying machines excel in ensuring uniform drying, a crucial factor for maintaining the desirable texture, authentic flavor, and essential nutritional value of food products. The precisely controlled environment diligently prevents overheating and guarantees that moisture is extracted evenly, resulting in consistently high-quality products. The suspended arrangement allows maximum surface area exposure to airflow, preventing uneven drying and ensuring consistent results across all surfaces of the food product. The controlled environment and precise airflow management further contribute to uniform drying.

2. Enhanced Product Quality: By using lower temperatures for drying, these machines prevent excessive browning or oxidation. The controlled drying conditions help to retain the natural flavors and aromas of the food products. This is particularly important for herbs and spices, where the flavor is the primary selling point.

3. Preservation of Nutritional Value: Drying at lower temperatures helps to preserve the nutritional content of the food products. High temperatures can destroy vitamins and other nutrients, reducing the nutritional value of the final product.

4. Increased Efficiency: Our machines are meticulously designed to dry substantial quantities of products simultaneously, significantly reducing the time and energy needed for effective drying. This efficiency directly translates into higher production capacity, streamlined operations, and substantially lower operational costs.

5. Energy Efficiency: A defining feature of hang-type drying machines is their utilization of advanced heat pump technology, which is demonstrably more energy-efficient than legacy drying methods. By delivering savings of up to 75% on electricity consumption, these machines offer a substantial reduction in your overall energy expenditure.

6. Versatility: Hang-type drying machines are highly versatile and can efficiently process a wide range of food products. This includes, but is not limited to, noodles, pasta variations, sausages, an assortment of fish, and more. In addition, they are capable of executing diverse drying processes, such as hot drying, cold drying, and specialized dehumidification.

7. Automation and Intelligent Control: Equipped with state-of-the-art control systems, hang-type drying machines provide automated operation, markedly reducing the need for manual intervention and ensuring consistent, repeatable results. This automation leads to fewer errors and more streamlined production. Modern hang type dryers feature intelligent digital controls that simplify operation. Users can program specific drying cycles tailored to different products, ensuring consistent results every time. These systems can also monitor and record data on temperature, humidity, and airflow, providing valuable insights into the drying process. Remote monitoring capabilities allow users to monitor the drying process from anywhere in the world. Predictive maintenance features can help to prevent breakdowns and minimize downtime.

8. Hygiene and Food Safety: Constructed with premium stainless steel, these machines are not only exceptionally durable but also easy to clean and maintain, while strictly adhering to all relevant food safety standards. The hygienic design actively prevents contamination, safeguarding the integrity and safety of the food products.

Applications in Food Processing

Hang type drying machines are versatile and can be used for various food products:

1. Noodles and Pasta: The suspended arrangement prevents noodles from clumping together, ensuring uniform drying without compromising their shape or texture. This is particularly important for delicate pasta shapes that are prone to sticking or breaking. Hang-type drying machines are ideally suited for the efficient drying of noodles and pasta products. Their unique design ensures that these delicate items maintain their intended shape and texture throughout the drying process. The precisely controlled environment diligently prevents cracking and ensures uniform drying, resulting in superior product quality.

- Detailed Process: The process begins by evenly distributing the freshly made noodles or pasta on specialized hangers. These hangers are then carefully loaded into the drying chamber. The system then initiates a precisely controlled drying cycle, where temperature, humidity, and airflow are meticulously managed to extract moisture gradually. This slow and controlled approach is essential to prevent the pasta from becoming brittle or cracking. Once the drying cycle is complete, the noodles or pasta retain their structural integrity, possessing the ideal texture and appearance coveted by food producers and consumers. The automated nature of these machines reduces the risk of human error and ensures consistency across every batch.

2. Sausages and Cured Meats: These machines provide a controlled environment for curing and drying meats, preventing harmful bacterial growth while enhancing flavor development. The controlled temperature and humidity allow for precise control over the drying rate, ensuring that the meat products develop the desired texture and flavor. These specialized machines are ideally suited for the controlled drying of sausages. They work to meticulously preserve their distinct flavor profiles and substantially extend their shelf life. The efficient hanging method facilitates even drying and prevents sausages from sticking together, ensuring each product meets quality standards.

- Enhancing Curing Processes: Hang-type drying machines play a pivotal role in enhancing the curing processes for various meats. By creating a precisely managed environment, they inhibit the growth of harmful bacteria while optimizing flavor development. The machines diligently control the temperature and humidity, facilitating the slow and uniform drying of the meat products. This meticulous drying process not only enhances the texture but also intensifies the unique flavors of the cured meats. In addition, this controlled environment effectively reduces the risk of spoilage, ensuring that the products meet stringent safety standards and boast an extended shelf life.

3. Fish and Seafood: Hang type dryers preserve nutritional value while preventing excessive shrinking or hardening during the drying process. The gentle drying conditions help to retain the natural flavors and aromas of the fish and seafood, resulting in a higher quality product. Hang-type drying machines are perfectly suited for drying various types of fish. They work to effectively maintain their crucial nutritional value and prevent spoilage. The meticulously controlled temperature and humidity levels guarantee optimal drying conditions, resulting in high-quality, safe-to-consume dried fish products.

- Maintaining Nutritional Integrity: The nutritional integrity of fish and seafood is meticulously maintained throughout the drying process. The hang-type drying machines work to prevent excessive shrinking or hardening, which can compromise the texture and flavor of the final product. The gentle drying conditions ensure that the natural flavors and aromas are retained, resulting in a high-quality end product that boasts both nutritional value and appealing taste profiles. This method enhances the overall appeal and marketability of dried seafood products.

4. Herbs and Spices: Low-temperature drying helps retain essential oils and flavors in herbs and spices, resulting in potent final products. High temperatures can degrade the essential oils and reduce the flavor intensity of the herbs and spices.

- Essential Oil Retention: Retaining essential oils is paramount when drying herbs and spices. Hang-type drying machines achieve this by employing low-temperature drying techniques. This method protects the delicate essential oils from degradation, ensuring that the final product is potent and flavorful. The controlled environment prevents the loss of volatile compounds, allowing the herbs and spices to retain their aromatic qualities. This, in turn, enhances the overall quality and market value of the products.

5. Fruits and Vegetables: Hang type drying can be used for fruits like apples, pears, and apricots, or vegetables such as tomatoes and peppers. The controlled environment ensures even moisture removal, preventing spoilage and maintaining nutritional content. Our innovative machines can be employed for drying a diverse range of meat products, including popular items like jerky and biltong. They meticulously ensure that these products are rendered safe for consumption and exhibit an extended shelf life, meeting the highest standards for both quality and safety.

- Preventing Spoilage and Preserving Nutrients: In the realm of fruits and vegetables, hang-type drying plays a vital role in preventing spoilage and preserving essential nutrients. The controlled environment facilitates even moisture removal, effectively inhibiting microbial growth and extending the shelf life of these perishable items. The gentle drying process helps retain vitamins, minerals, and antioxidants, ensuring that the dried fruits and vegetables remain a nutritious option for consumers. This method enhances the overall quality and marketability of dried produce.

Advanced Technologies Integrated into Hang Type Drying Machines

1. Smart Sensors and IoT Integration: Modern hang type dryers often incorporate smart sensors and Internet of Things (IoT) integration. These technologies allow for real-time monitoring and control of the drying process. Sensors can detect moisture levels, temperature variations, and airflow patterns within the drying chamber. This data is then transmitted to a central control system, where it can be analyzed to optimize the drying process. IoT integration enables remote monitoring and control, allowing operators to adjust settings and receive alerts from anywhere in the world. This advanced connectivity improves efficiency, reduces downtime, and enhances product quality.

2. Automated Loading and Unloading Systems: Automated loading and unloading systems can significantly reduce labor costs and improve efficiency. These systems use robotic arms or conveyor belts to automatically load and unload the drying chamber. This eliminates the need for manual handling, reducing the risk of contamination and ensuring consistent loading patterns. Automated systems can also be programmed to handle different types of products, providing versatility and flexibility.

3. Advanced Airflow Management: Proper airflow is essential for uniform drying. Advanced airflow management systems use computational fluid dynamics (CFD) to optimize airflow patterns within the drying chamber. These systems ensure that air is evenly distributed across all surfaces of the food products, preventing hot spots and ensuring consistent drying. Adjustable baffles and diffusers allow operators to fine-tune airflow patterns based on the specific characteristics of the product being dried.

4. Predictive Maintenance: Predictive maintenance uses machine learning algorithms to analyze data from sensors and identify potential maintenance issues before they lead to breakdowns. This allows operators to schedule maintenance proactively, minimizing downtime and reducing the risk of costly repairs. Predictive maintenance can also help to optimize the performance of the drying machine, ensuring that it operates at peak efficiency.

5. Heat Recovery Systems: Heat recovery systems capture and reuse waste heat from the drying process, further improving energy efficiency. These systems can use heat exchangers to transfer heat from the exhaust air to the incoming air, reducing the amount of energy needed to heat the drying chamber. Heat recovery systems can also be used to preheat water or other fluids, providing additional energy savings.

Customization Options

Manufacturers often provide customization options for hang type drying machines to meet specific requirements:

1. Modifications to hanger design

2. Adjustments in chamber size

3. Custom air circulation systems

4. Tailored control systems

This flexibility ensures optimal results for various food types with differing moisture content. The materials used in the construction of the drying machine can be customized to suit the specific needs of the food product. For example, stainless steel is often used for its corrosion resistance and ease of cleaning, while other materials may be used for their thermal properties. Automation features can be added to the drying machine to reduce labor costs and improve efficiency. These features can include automatic loading and unloading systems, as well as automated cleaning and sanitization systems.

Case Studies

1. Noodle Production: A large noodle manufacturer replaced their traditional tray dryers with hang type drying machines and saw a significant improvement in product quality and efficiency. The noodles dried more evenly, with less breakage and clumping, leading to higher customer satisfaction and reduced waste.

2. Sausage Curing: A sausage producer implemented hang type drying machines for their curing process and was able to reduce the curing time by 30% while maintaining the desired flavor and texture. The controlled environment of the drying machine also helped to prevent bacterial growth, improving food safety.

Conclusion

Hang type drying machines represent a significant advancement in food processing technology. Their ability to provide efficient, uniform drying while preserving food quality makes them an invaluable tool for manufacturers worldwide. With energy-efficient designs and customizable features, these machines are poised to play a crucial role in the future of food processing. The precise control, energy efficiency, and versatility of these machines make them an essential investment for any food processing operation looking to improve product quality, reduce costs, and enhance sustainability.

FAQ

1. What types of foods can be dried using hang type dryers?

Hang type dryers are suitable for a variety of foods including noodles, sausages, fish, herbs, and spices due to their ability to provide even airflow and controlled conditions. They are also effective for fruits, vegetables, and other items that benefit from uniform drying.

2. How do hang type dryers ensure even drying?

The suspended arrangement allows maximum surface area exposure to airflow, preventing uneven drying and ensuring consistent results across all surfaces of the food product. The controlled environment and precise airflow management further contribute to uniform drying.

3. What are the energy savings associated with heat pump technology?

Heat pump technology can result in energy savings of up to 75% compared to traditional drying methods by recycling heat within the system. This reduces energy consumption and lowers operating costs.

4. Can hang type dryers be customized?

Yes, manufacturers often provide customization options such as modifications to hanger design, adjustments in chamber size, custom air circulation systems, and tailored control systems to meet specific requirements.

5. How do intelligent controls enhance operation?

Intelligent digital controls simplify operation by allowing users to program specific drying cycles tailored to different products, ensuring consistent results every time. These systems can also monitor and record data on temperature, humidity, and airflow, providing valuable insights into the drying process.

Citations:

[1] https://www.dryeratech.com/hang-type-drying-machines-a-game-changer-for-food-processing.html

[2] https://www.dryeratech.com/maximize-efficiency-with-hang-type-drying-machines.html

[3] https://patents.google.com/patent/CN110207480A/zh

[4] https://www.dryeratech.com/hang-type-dryers-the-secret-to-perfectly-dried-products.html

[5] https://www.gosuburban.com/tsunami/blog/industrial-air-dryers-for-oil-gas-industry

[6] https://patents.google.com/patent/CN112481977B/zh

[7] https://gcwgandhinagar.com/econtent/document/1588156026Unit%20V%20Types%20of%20dryers%20and%20their%20applications.pdf

[8] https://www.ifsqn.com/forum/index.php/topic/31165-is-the-use-of-hand-dryers-acceptable-in-the-food-industry/