When it comes to fruit processing, one of the most crucial steps is the drying process. The fruit dryer machine plays a vital role in transforming fresh fruits into dried, nutrient-packed snacks or ingredients for various recipes. However, the efficiency of this machine can significantly impact the quality, yield, and ultimately, the profitability of your operation. In this blog post, we'll explore various ways to optimize the efficiency of your fruit dryer machine for the best results.

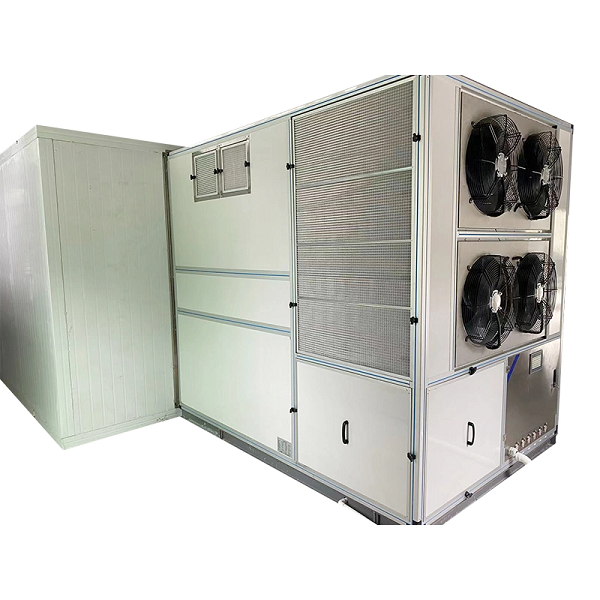

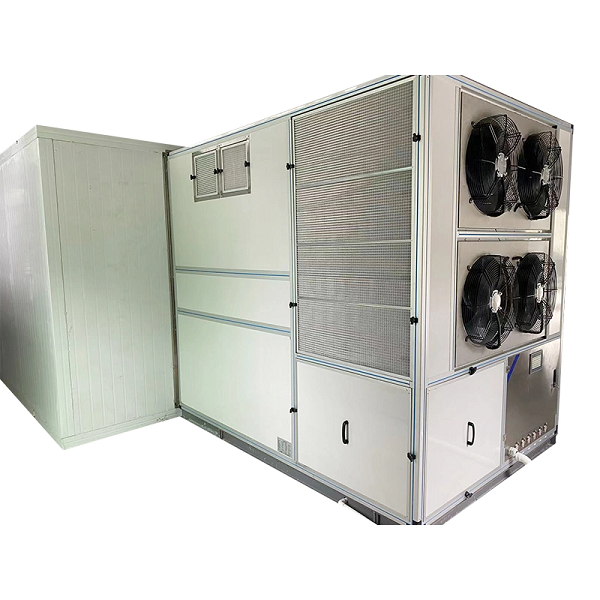

Before delving into optimization strategies, it's essential to have a basic understanding of how a fruit dryer machine works. In its most basic form, a fruit dryer machine uses heat to evaporate moisture from the fruit, resulting in a dried product. However, there are several types of fruit dryers, including convection dryers, vacuum dryers, and microwave dryers, each with its unique set of operating principles and advantages.

Choosing the Right Fruit Dryer for Your Needs

The first step in optimizing your fruit dryer machine's efficiency is to ensure you've chosen the right type of dryer for your specific needs. Different fruits have varying moisture content, texture, and nutritional profiles, and thus, require different drying methods. For example, delicate fruits like berries may require a gentle drying method like vacuum drying, while heartier fruits like apples can tolerate higher temperatures and faster drying rates using convection drying.

Optimizing Operating Parameters

Once you've selected the right fruit dryer, it's time to optimize its operating parameters. Here are a few key factors to consider:

●Temperature Control: Temperature plays a crucial role in the drying process. Too high a temperature can damage the fruit's nutritional value and color, while too low a temperature can result in incomplete drying. It's essential to find the optimal temperature range for your specific fruit and adjust the dryer accordingly.

●Airflow and Humidity Control: Proper airflow is necessary to ensure even distribution of heat and moisture removal. Adjusting the airflow rate and humidity levels can help optimize the drying process, preventing moisture pockets and ensuring complete drying.

●Loading Density: The amount of fruit loaded into the dryer also affects its efficiency. Too much fruit can hinder airflow, leading to incomplete drying, while too little fruit may result in wasted energy. Finding the right loading density for your specific fruit and dryer type is crucial.

●Drying Time: The duration of the drying process is another important factor to consider. Over-drying can degrade the fruit's quality, while under-drying can lead to moisture-related issues. Experimenting with different drying times and monitoring the results can help you determine the optimal drying time for your fruit.

Maintenance and Cleaning

Regular maintenance and cleaning are essential for maintaining your fruit dryer's efficiency. Here are a few tips:

●Cleaning the Drying Chamber: Over time, residue from the fruit can build up in the drying chamber, affecting airflow and heat transfer. Regularly cleaning the chamber with a suitable cleaning agent can help restore its efficiency.

●Inspecting and Replacing Filters: Filters play a crucial role in removing dust and debris from the airflow, ensuring clean, healthy drying conditions. Inspect filters regularly and replace them when necessary.

●Lubricating Moving Parts: Moving parts like fans and motors require proper lubrication to function efficiently. Use the recommended lubricant and follow the manufacturer's guidelines for lubricating your fruit dryer's moving parts.

●Checking Heating Elements: Heating elements are the heart of any fruit dryer. Regularly checking them for damage or wear and tear and replacing them as needed can help maintain your dryer's efficiency.

Monitoring and Troubleshooting

Monitoring your fruit dryer's performance and troubleshooting any issues that arise is crucial for maintaining its efficiency. Here are a few tips:

●Installing Temperature and Moisture Sensors: Installing sensors inside the drying chamber can help you monitor the temperature and moisture levels during the drying process. This information can be used to make adjustments to optimize the drying conditions.

●Regularly Inspecting the Dried Fruit: Regularly inspecting the dried fruit for quality issues like discoloration, shrinkage, or incomplete drying can help you identify problems with your dryer's performance.

●Recording Operating Data: Recording operating data like temperature, humidity, airflow rate, and drying time can help you identify patterns and trends in your dryer's performance. This information can be used to make adjustments to optimize efficiency.

●Troubleshooting Common Issues: Issues like overheating, poor airflow, or incomplete drying are common with fruit dryers. Familiarizing yourself with these issues and knowing how to troubleshoot them can help you resolve problems quickly and efficiently.